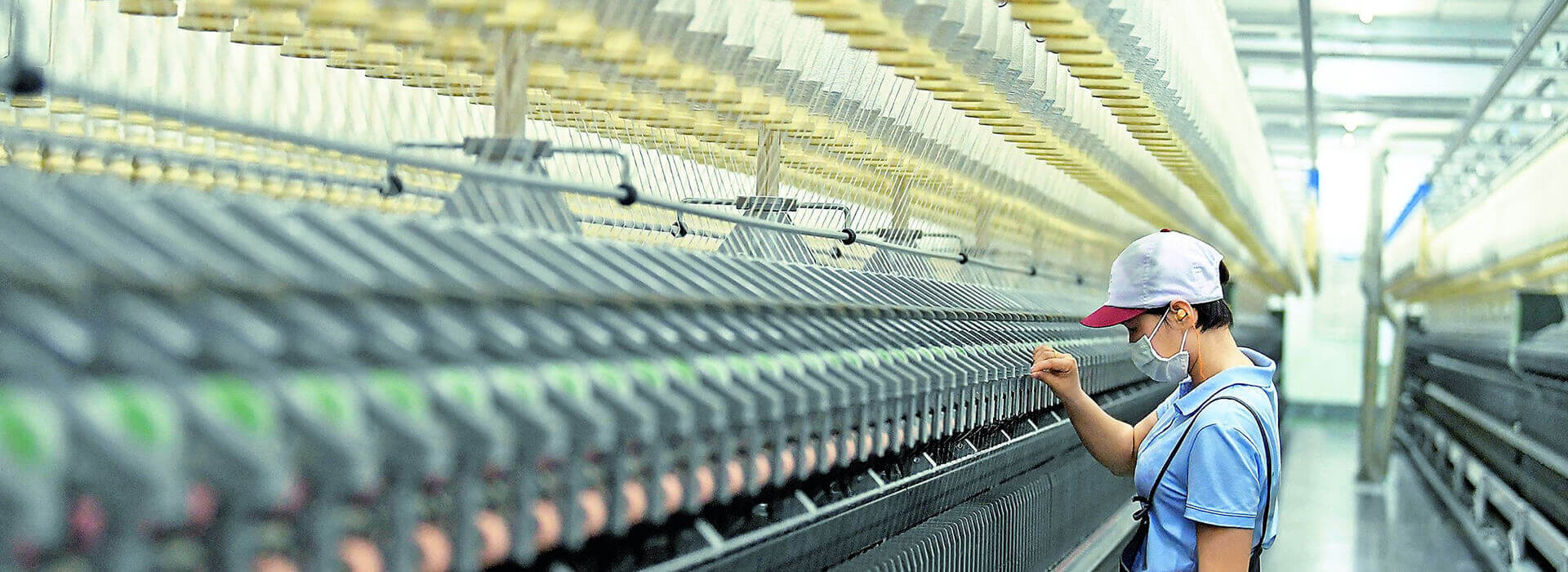

Daily factory management encompasses product and warehouse management, quality and asset monitoring, and personnel and production line allocation. Traditional management largely depends on people, which is suitable for those small factories. However, when the orders are mounting and the technique complicated, traditional management's backsides emerge.

The disadvantages, low efficiency, high error rate, and low precision, will dampen productivity. Luckily, the developed RFID devices can greatly remedy those questions, which will further unleash the potential of the manufacturing industries. So, how do RFID devices digitize the industry, gaining the industry stronger momentum? This passage may give you some hints.

How RFID Devices Process

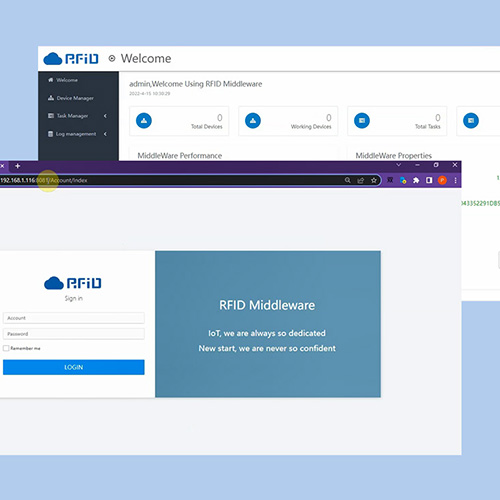

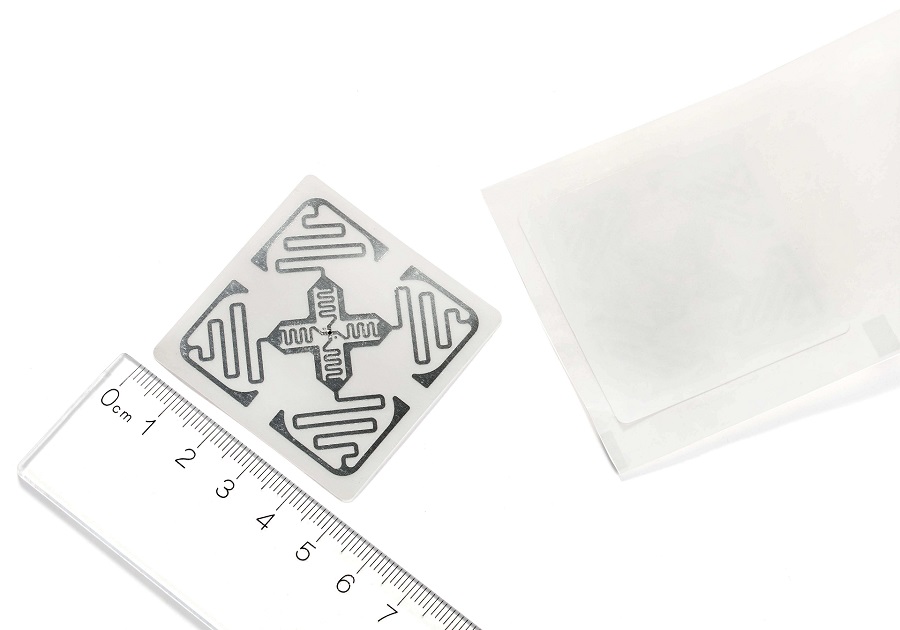

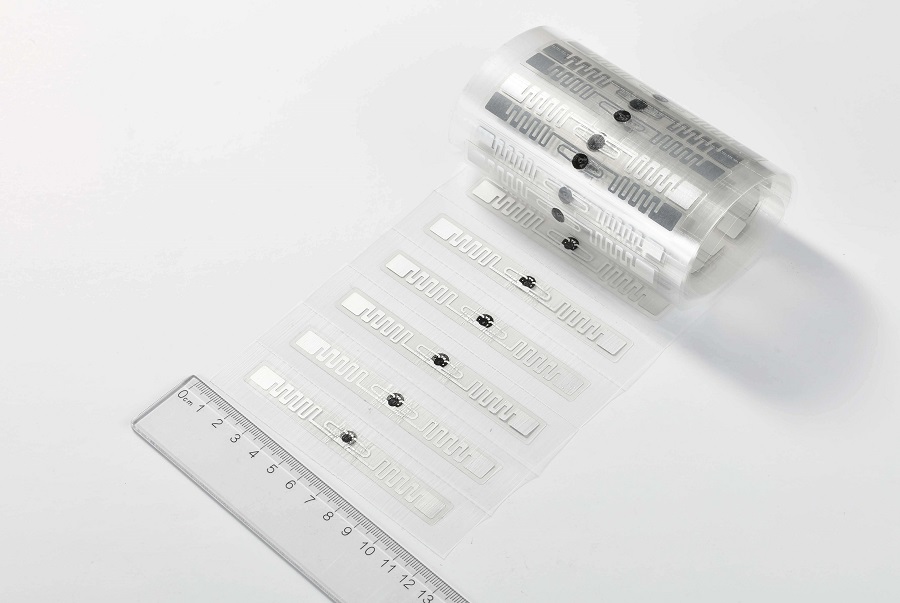

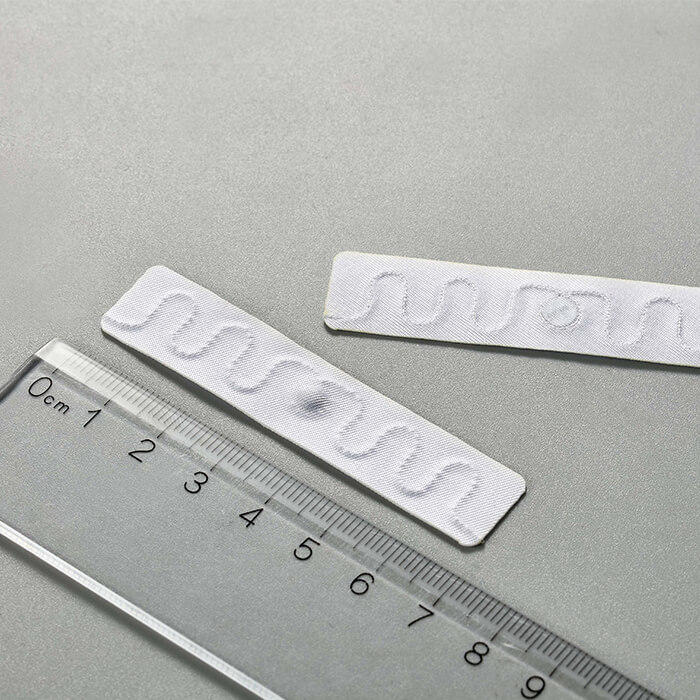

Production lines and warehouses that adopt RFID devices, including RFID antennae, readers, and tags, can achieve automatic and real-time monitoring and management. So here is a more detailed description of their application in the whole manufacturing factory.

- RFID Devices in Production Lines

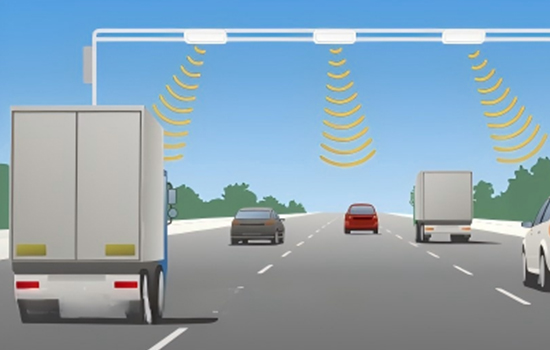

In the production line management, UHF RFID readers and RFID antennae are installed at every spot. Then When goods with RFID tags enter the identity scope of RFID readers, the information in the tags will be identified and transmitted to the management system, which then will project the related information on the UHF RFID readers' screen to remind workers of the following steps.

In this area, RFID devices have unexceptional advantages. It is because they can facilitate automatic data reading and their excellent ability to resist harsh working environments. Their introduction adds flexibility to the production lines management, speeds up the response, and has a low requirement on the communications system.

Speed and precision are the main two gauges to measure the capability of the production lines and the manufacturer. So smart production lines are getting their popularity in pharmacy, foods, logistics, vehicles, and tobacco manufacturing.

- RFID Devices in Warehouse Management

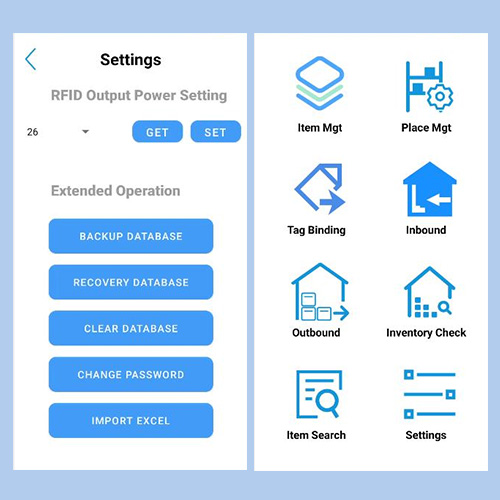

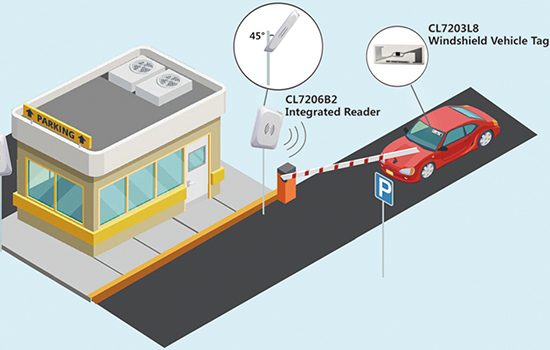

More and more enterprises realize that RFID devices can read data rapidly, even amid a high amount of goods. Besides, they are durable and can be used for source retracing and anti-counterfeiting. Generally speaking, they can slack the cost and increase efficiency. But how to achieve it?

After being fully processed, the goods need to be transported to the warehouses from the production lines. Therefore, the entrances and exits can adopt the stagnant RFID readers, and the managers can grab the handheld RFID readers, which combined can facilitate the data collection and verification in delivery processes, making the storage, picking, stock taking, and removing an easy task. This is how RDID devices digitize warehouse management – striking a balance between manual workers and technology.

Hopeland RFID Devices for Recommendation

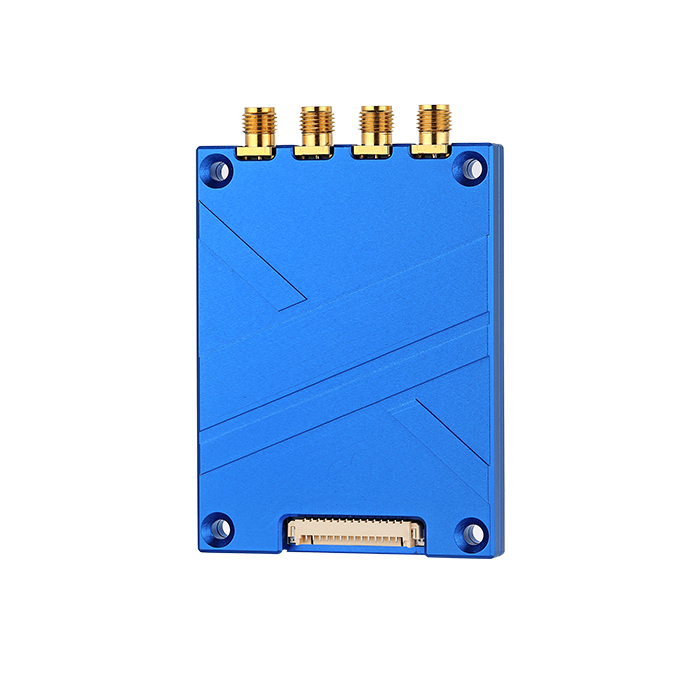

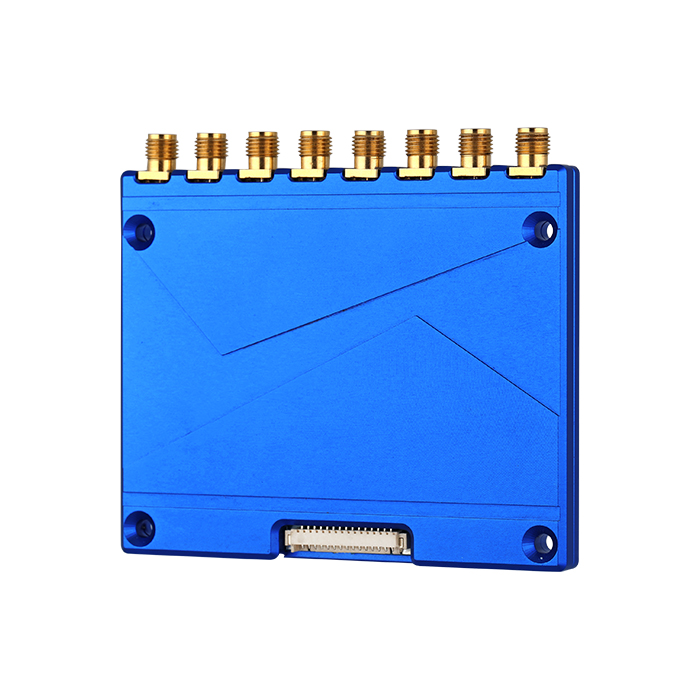

HT100 is our updated, lightweight, exquisite, integrated reader that adapts Impinj RAIN E510, a powerful chip that empowers the reader with greater efficiency and reliability. It is an outstanding RFID device serving multiple uses in the manufacturing industry, in particular. It supports both automatic and commands tag reading mode for different demands. It also boasts an advanced configuration enterprise-grade data capture and reading capability that can facilitate the management process.

It is the upgraded mode of HT100. In light of all the advantages of HT100, HT100W also allows online and remote upgrades that can further slack the effort on maintenance. Besides, both Hopeland RFID readers can withstand harsh environments with extreme temperatures and humidity.

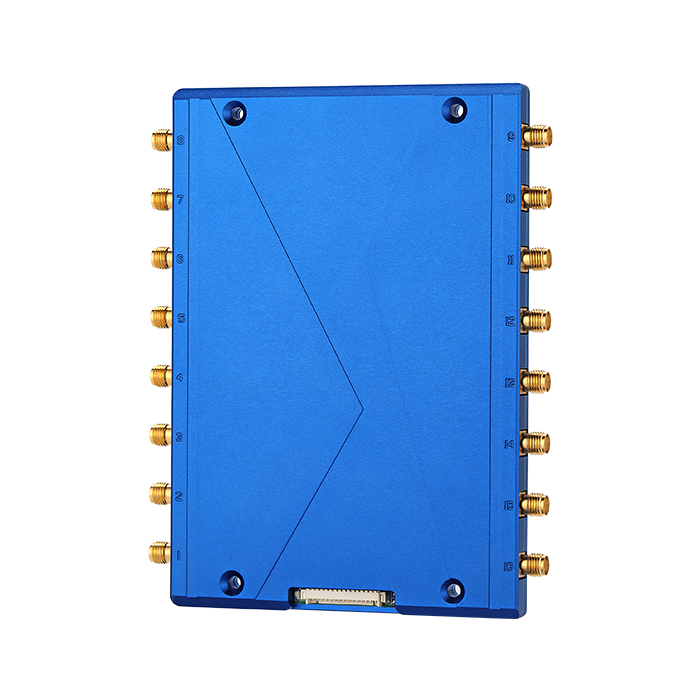

- HT112W

The HT112W is a new-class industrial integrated reader adopting advanced Hopeland technology that can offer high visibility to the goods with RFID tags. It has low power

consumption but a large power supply that allows it to work longer and stabler. The introduction of the Hopeland RFID reader in the factory will streamline the working process, reduce cost, and smoothen production.

Conclusion

You may have a clear vision of how RFID devices digitize the manufacturing industry. To refresh your factories, time to introduce Hopeland's RFID devices. For more information about RFID in manufacturing, come and visit our website. Here offered more information for you to get to know RFID devices.