IoT 8-port Android RFID Reader

Features

-

Using Impinj R2000/E710 chip

Using Impinj R2000/E710 chip -

Open development environment based on Android OS

Open development environment based on Android OS -

MT6765 processor, octa-core 2.3GHz, 64GB ROM+4GB RAM

MT6765 processor, octa-core 2.3GHz, 64GB ROM+4GB RAM -

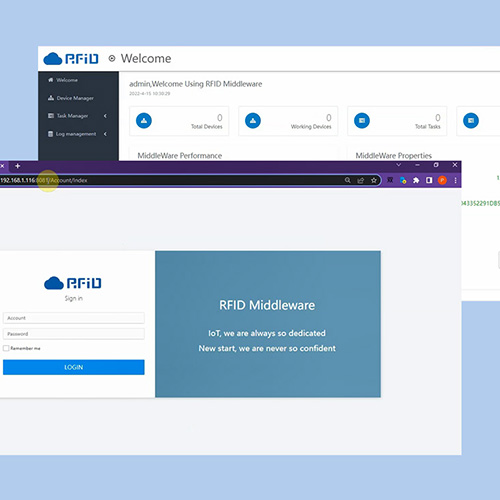

Supports MQTT to send data to Cloud server

Supports MQTT to send data to Cloud server -

Support HTTP POST to send tag data to a web URL directly

Support HTTP POST to send tag data to a web URL directly -

Supports sending data to the database directly

Supports sending data to the database directly -

RJ45, RS485, Wiegand, USB, Bluetooth, WiFi, 4G

RJ45, RS485, Wiegand, USB, Bluetooth, WiFi, 4G -

Support antenna port detection, online updates

Support antenna port detection, online updates -

Supports RSSI and tag data filtering

Supports RSSI and tag data filtering

Highlights

Specifications

-

System

Processor MT6765, Octa Core 2.3Ghz Operation System Android 9.0 Firmware upgrade Demo software/Web page Special function Automatic card reading

Data cache

Data filtering

Can support RF/EM temperature sensor chip

Support MQTT

Support HTTP POST

Support data transfer to specified database

NTP support

API Windows system– .Net / .Net core / C++ / Java SDK

Android system- Java

Linux system – Java, SDKMemory ROM 64GB; RAM 4GB -

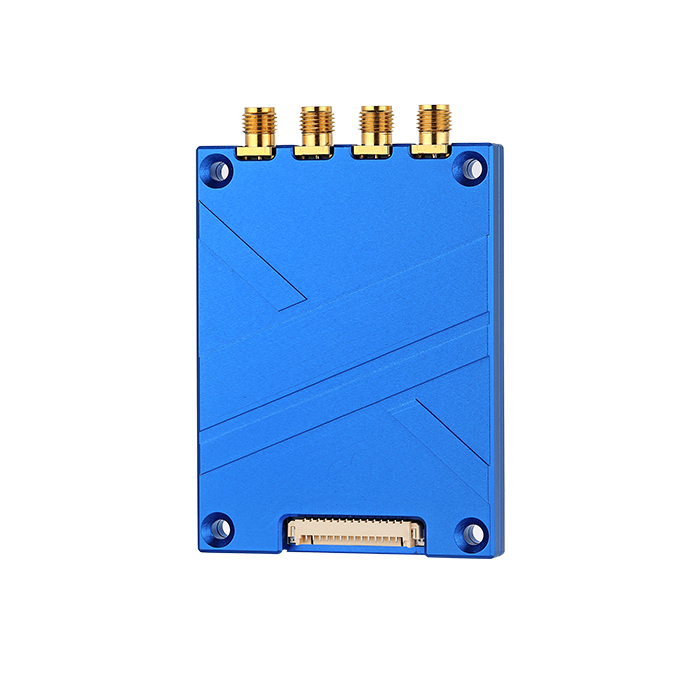

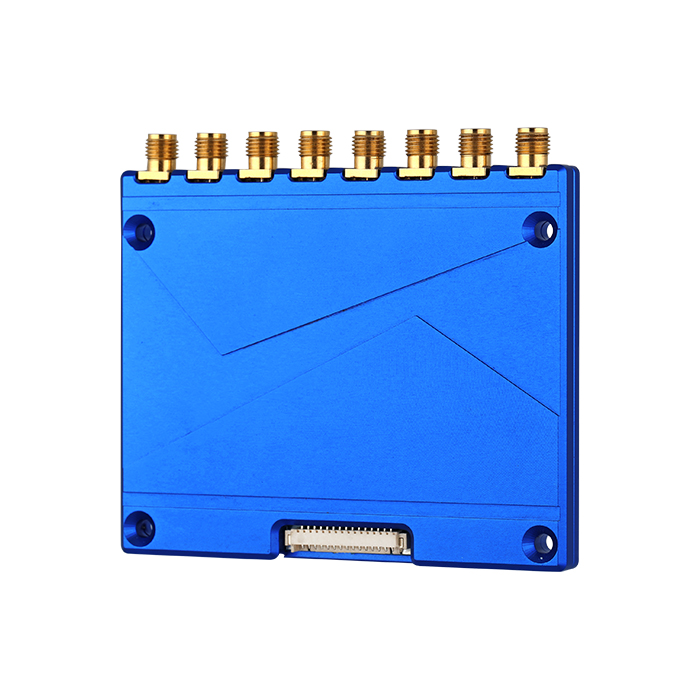

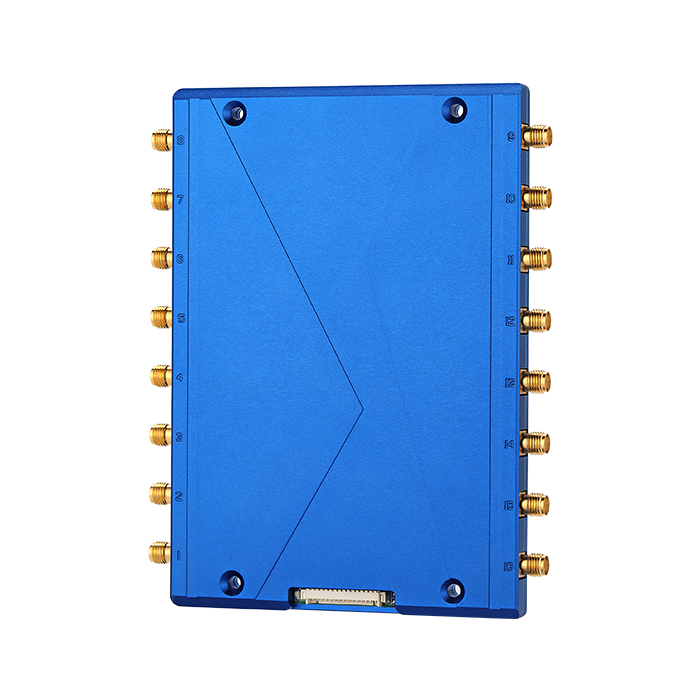

Physical

Dimension 241mm×132mm×36mm Weight 1.0Kg Material Die-cast Aluminum Status indication Power, working status, antenna port, WiFi, 4G, Bluetooth Power consumption 25W Communication RJ45, RS485, OTG, Wiegand

WiFi: 802.11 a/b/g/n/ac

4G: LTE-FDD (CAT-7)/LTE-TDD (CAT-7)/WCDMA/TD-SCDMA/

EVDO/CDMA/GSM

Bluetooth: BT v2.1+EDR, 3.0+HS, v4.1+HSI/O ports 4 optocoupler input (DC 0~4V), 4 relay output Power Supply DC 24V/2.5A (DC 9V~30V,60W) or POE(IEEE 802.3 af/at/bt) Display HDMI, 720P/1080P Antenna port 8 RP-TNC -

RFID

Air Protocols

ISO/IEC18000-6B, 6C / EPC C1Gen2 C2GEN2 optionalFrequency USA: 902 MHz-928MHz (FCC part 15)

CN: 920-925MHz (CMIIT)

Russian / Brazil / Korea / Malaysia / Thailand / other customizableOutput Power 0dBm-35dBm (±1dBm) adjustable Channel bandwidth <200KHz Anti-collision Support multi-tag / intensive inventory Work Mode Fixed/hop frequency optional -

Environment

Operating temperature -20℃~+70℃ Storage temperature -40℃~+85℃ Humidity 5%RH~95%RH(no condensation) Protection level IP53

Applications

Smart Retail

RFID Smart Refrigerator

With the rising cost of human resources and the increasing demand for the ultimate shopping experience, consumers are more comfortable with access to food and beverages anytime and anywhere. This has led to the emergence of smart new retail methods such as unmanned convenience stores, smart refrigerators, and smart vending machines. Among them, unmanned vending machines are one of the most common ones in daily life.

At same time, retail companies need to track all goods inventory status, improve operational efficiency, save labor cost and analysis customer's purchase trend to increase revenue. RFID technology can help them achieve it effortlessly. Nowadays, RFID technology is widely used in retail. The automatic retail fridge is built with RFID UHF hardware, so that retailers can track the goods status at any time. More importantly, smart RFID refrigerators enable buyer to finish purchase process alone and automatically.

At same time, retail companies need to track all goods inventory status, improve operational efficiency, save labor cost and analysis customer's purchase trend to increase revenue. RFID technology can help them achieve it effortlessly. Nowadays, RFID technology is widely used in retail. The automatic retail fridge is built with RFID UHF hardware, so that retailers can track the goods status at any time. More importantly, smart RFID refrigerators enable buyer to finish purchase process alone and automatically.

View Details

Smart Retail

Smart Retail Store

Pain points in traditional retail stores

Operating aspects:

The operating costs of common convenience stores continue to rise

The cost of rent

convenience stores and merchants are more and more concerned with the capital. But the store resources are relatively scarce, and the pressure on the rising cost of rent will continue to exist in the future.

Labor costs

The decline of the working age workforce increases the labor cost. The increase of convenience store staff mobility and the increase of personnel costs and management costs.

The cost of water and electricity

The relative area is larger and the water power consumption is more.

Consumer aspects:

Purchasing daily necessities is inconvenient and far away.

There is no 24-hour store in the evening, and difficult to meet any emergency.

Operating aspects:

The operating costs of common convenience stores continue to rise

The cost of rent

convenience stores and merchants are more and more concerned with the capital. But the store resources are relatively scarce, and the pressure on the rising cost of rent will continue to exist in the future.

Labor costs

The decline of the working age workforce increases the labor cost. The increase of convenience store staff mobility and the increase of personnel costs and management costs.

The cost of water and electricity

The relative area is larger and the water power consumption is more.

Consumer aspects:

Purchasing daily necessities is inconvenient and far away.

There is no 24-hour store in the evening, and difficult to meet any emergency.

View Details

Industry 4.0

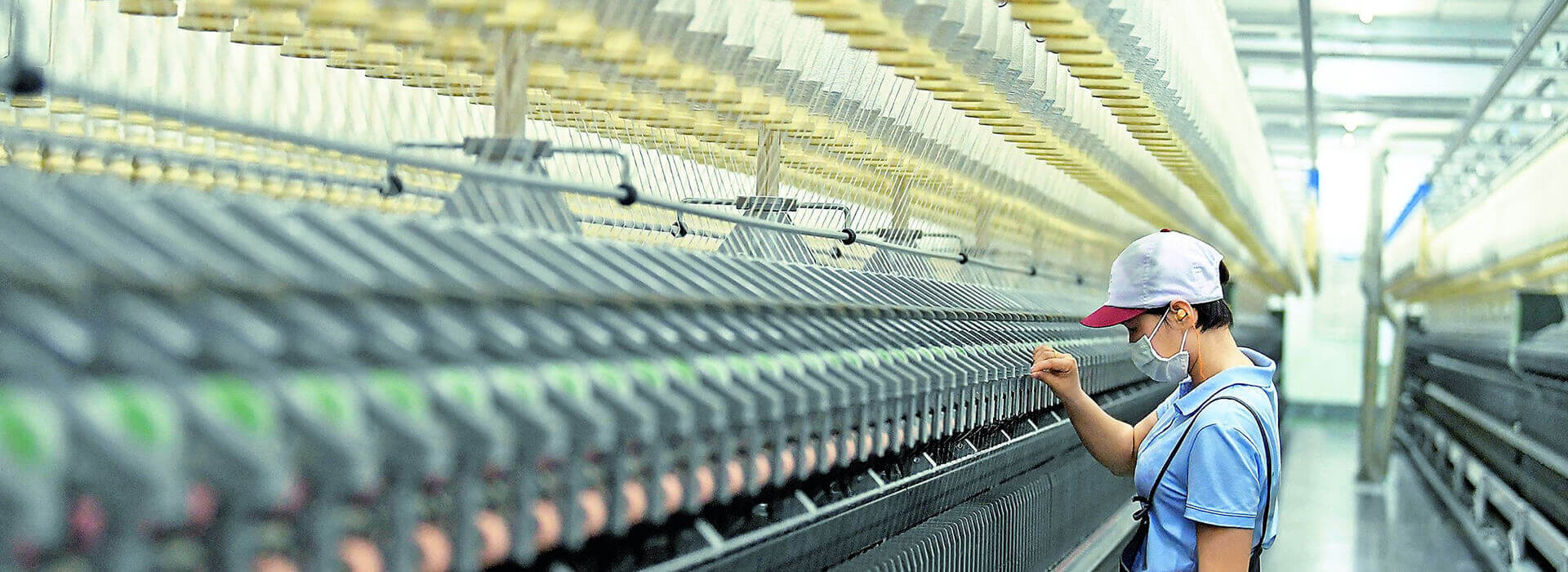

Textile Production

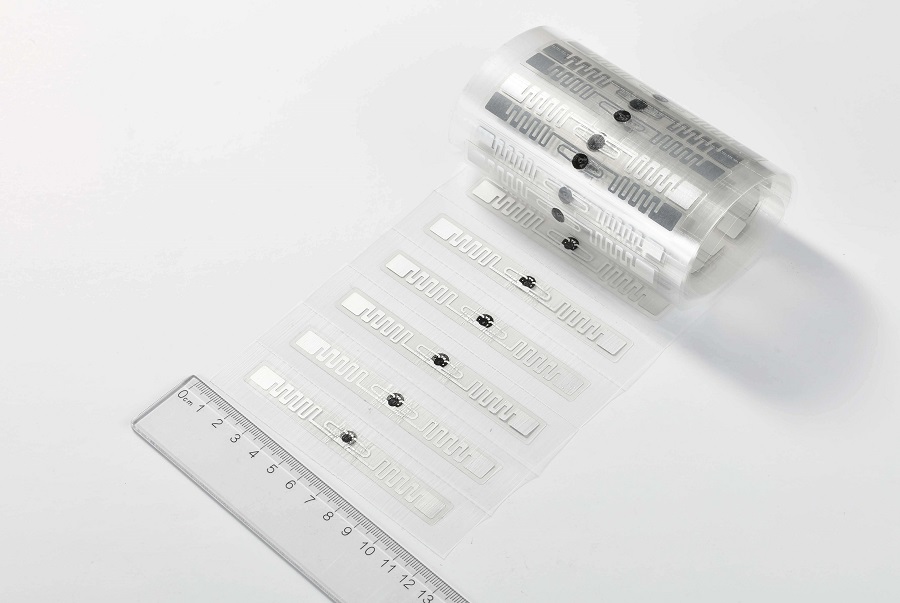

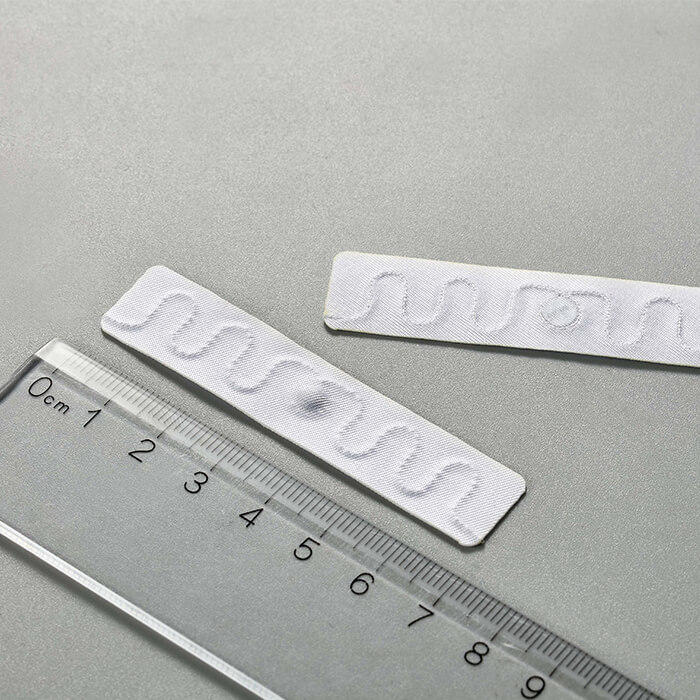

At present, bar code scanners are used to scan the labels outside the box one by one in the weaving and weaving yarn bins and winding in and out warehouses. The average daily scanning time is more than 28 hours and the workload is large, which wastes a lot of manpower and is not efficient.

The modern warehouse management system based on RFID technology can automatically complete the scanning of multiple labels at one time, save time and manpower, effectively achieve the accuracy of inventory, detect idle weft yarns in time, and improve the efficiency of management weft allocation. Cooperate with automatic assembly line, AGV, manipulator and other equipment, use RFID technology to intelligently perceive equipment and materials, realize production automation, real-time and visualize warehouse management, and use special mobile terminals to achieve fast and accurate inventory. The successful implementation of the project will provide strong support for the information process of the subsequent automated allocation warehouse.

The modern warehouse management system based on RFID technology can automatically complete the scanning of multiple labels at one time, save time and manpower, effectively achieve the accuracy of inventory, detect idle weft yarns in time, and improve the efficiency of management weft allocation. Cooperate with automatic assembly line, AGV, manipulator and other equipment, use RFID technology to intelligently perceive equipment and materials, realize production automation, real-time and visualize warehouse management, and use special mobile terminals to achieve fast and accurate inventory. The successful implementation of the project will provide strong support for the information process of the subsequent automated allocation warehouse.

View Details

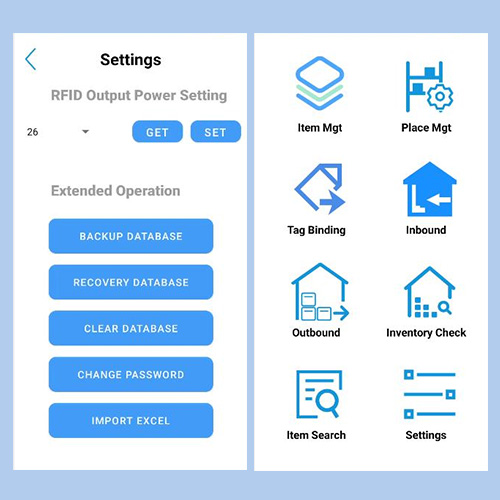

Asset Management

Tool Management Solutions

Traditional tool management methods generally rely on non-automated, paper-based systems to record, track and manage; a few use barcodes to identify and manage assets; but the efficiency is extremely low, with the increase in the number of assets, extremely The earth has increased the burden of management personnel, a serious waste of human resources, and also increased the difficulty of tool management, often resulting in untimely data and high error rates. Often the inventory management is chaotic, and the inbound and outbound data is wrong. If it is left to exist on a large scale for a long time, it will bring great cost problems to the enterprise.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

View Details

Send A Message

Related Products

-

HH100Android Integrated RFID readerNew Shine serie - Android Integrated RFID reader HH100 Smart IoT device with integrated design but support 1 additional antenna port. Running with Impinj Indy R2000 chipset/ newest Impinj E710 RAIN RFID reader chip upgradable, and operated on Otca-core Android 9.0 operation system. It not only includes built-in 4G, WiFi, and Bluetooth as standard, and PoE (IEEE 802.3 af/at/bt) optional, but also supports built-in web management functions such as remote parameter configuration, MQTT, HTTP post, MySQL database transferring and so on.Details

-

HY820UHF RFID handheld terminalImpinj E710 Supportable,UHF 25M Read Range;Industrial IP65 Rugged,1.5M Drop Test,Suitable For Different Harsh EnvironmentDetails

-

HL7202K8Bluetooth UHF Handheld ReaderHL7202K8 Bluetooth Handheld Reader Support Bluetooth V4.2/2.1+EDR,Exquisite Appearance, High Protection Level, Comfortable And Simple Operation, Easy To Carry, High Flexibility, Suitable To Use In Various EnvironmentDetails

-

HZ5101-port UHF RFID ModuleHZ510 module is a miniaturized UHF RFID reading and writing module. The core component adopts R2000 as the core platform. R2000 is a high-performance and highly integrated reader and writer IC, which integrates the functions of analog RF front-end and baseband digital signal processing module.Details