i3 RFID Portal Access Control RFID Tracking Gate

Features

-

Powered by Impinj R2000/E710 chipset for maximum tag detection performance.

Powered by Impinj R2000/E710 chipset for maximum tag detection performance. -

Built-in infrared sensor, which can trigger tag reading, or judge the entry and exit.

Built-in infrared sensor, which can trigger tag reading, or judge the entry and exit. -

Built-in alarm light and buzzer, sensitive alarm, safe and reliable

Built-in alarm light and buzzer, sensitive alarm, safe and reliable -

The antenna is specially designed to achieve a horizontal narrow beam design for accurate signal coverage with no blind spots.

The antenna is specially designed to achieve a horizontal narrow beam design for accurate signal coverage with no blind spots. -

Optional LED display to connect to an external computer via HDMI port to display apps

Optional LED display to connect to an external computer via HDMI port to display apps -

Support RSSI, antenna detection, online update

Support RSSI, antenna detection, online update

Highlights

Specifications

-

HARDWARE, OS AND FIRMWARE MANAGEMENT

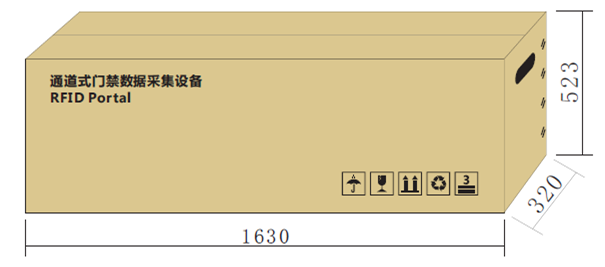

Processor ARM9, 400MHz Memory Flash 128MB;DRAM 32 MB Operating System: Linux 2.6 Display 13.1″ TFT LED Capacitive touch screen, 1920*1080 (optional) Firmware Upgrade Windows – .NET, C++ and Java SDK Dimensions 1500(H) * 385(W) * 45mm(T) Weight One pair, about 20kg -

RFID CHARACTERISTICS

Air Protocols ISO/IEC 18000-6B,6C/EPC C1Gen2、C2Gen2,GB/T 29768-2013 Frequency USA: 902 MHz-928MHz (FCC part 15)

EU: 865-868MHz (ETSI EN 302208)Output Power: 0dBm-35dBm (±1dBm) adjustable Channel bandwidth: <200KHz Reading Distance 0-4m (Pre-factory setting) Anti-collision Support multi-tag / intensive inventory Work Mode: Fixed/hop frequency optional -

CONNECTIVITY

Communications RJ45, RS232, optional HDMI video/touch interface Power supply DC 24V/2.5A (DC 9V ~ 30V,60W) -

ENVIRONMENTAL

Operating Temp. -20℃~+70℃ Storage Temp. -40℃~+85℃ Humidity 5%RH~95%RH 无冷凝 (+25℃) Sealing IP45

Applications

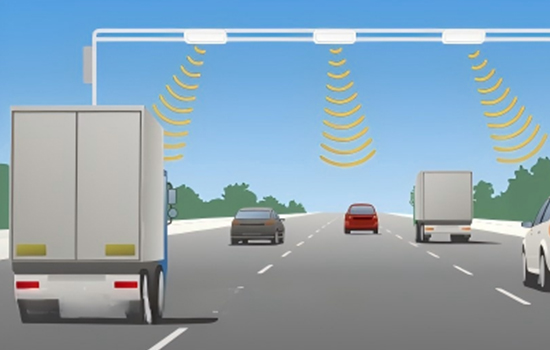

Warehousing & Logistics

Smart Warehousing

Modern warehouse storage is not only to complete the simple batch processing of goods in and out, but also to make clear database records of the types, quantities, production attributes, stacking positions and other information of goods in the warehouse. In order to obtain accurate product data and supply chain information at all stages of the logistics chain.

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

View Details

Smart Retail

Smart Retail Store

Pain points in traditional retail stores

Operating aspects:

The operating costs of common convenience stores continue to rise

The cost of rent

convenience stores and merchants are more and more concerned with the capital. But the store resources are relatively scarce, and the pressure on the rising cost of rent will continue to exist in the future.

Labor costs

The decline of the working age workforce increases the labor cost. The increase of convenience store staff mobility and the increase of personnel costs and management costs.

The cost of water and electricity

The relative area is larger and the water power consumption is more.

Consumer aspects:

Purchasing daily necessities is inconvenient and far away.

There is no 24-hour store in the evening, and difficult to meet any emergency.

Operating aspects:

The operating costs of common convenience stores continue to rise

The cost of rent

convenience stores and merchants are more and more concerned with the capital. But the store resources are relatively scarce, and the pressure on the rising cost of rent will continue to exist in the future.

Labor costs

The decline of the working age workforce increases the labor cost. The increase of convenience store staff mobility and the increase of personnel costs and management costs.

The cost of water and electricity

The relative area is larger and the water power consumption is more.

Consumer aspects:

Purchasing daily necessities is inconvenient and far away.

There is no 24-hour store in the evening, and difficult to meet any emergency.

View Details

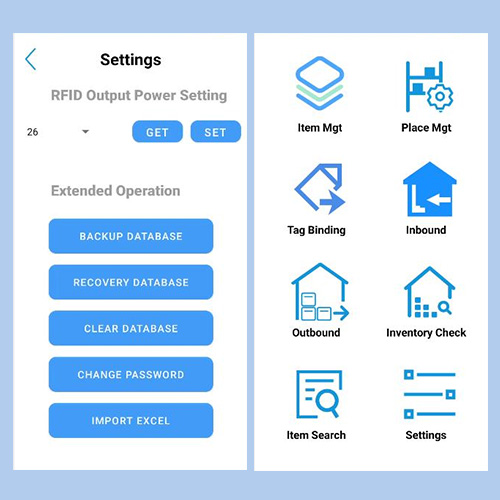

Asset Management

Tool Management Solutions

Traditional tool management methods generally rely on non-automated, paper-based systems to record, track and manage; a few use barcodes to identify and manage assets; but the efficiency is extremely low, with the increase in the number of assets, extremely The earth has increased the burden of management personnel, a serious waste of human resources, and also increased the difficulty of tool management, often resulting in untimely data and high error rates. Often the inventory management is chaotic, and the inbound and outbound data is wrong. If it is left to exist on a large scale for a long time, it will bring great cost problems to the enterprise.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

View Details

Send A Message

Related Products

-

HZ380Cost-effective 8 Ports ReaderCost-effective multi-port fixed UHF RFID reading and writing device, supports ISO18000-6C/6B two protocols, output power 0 ~ 30dBm optional, with high recognition sensitivity, fast speed, strong anti-interference ability , Multi-antenna identification efficiency.Details

-

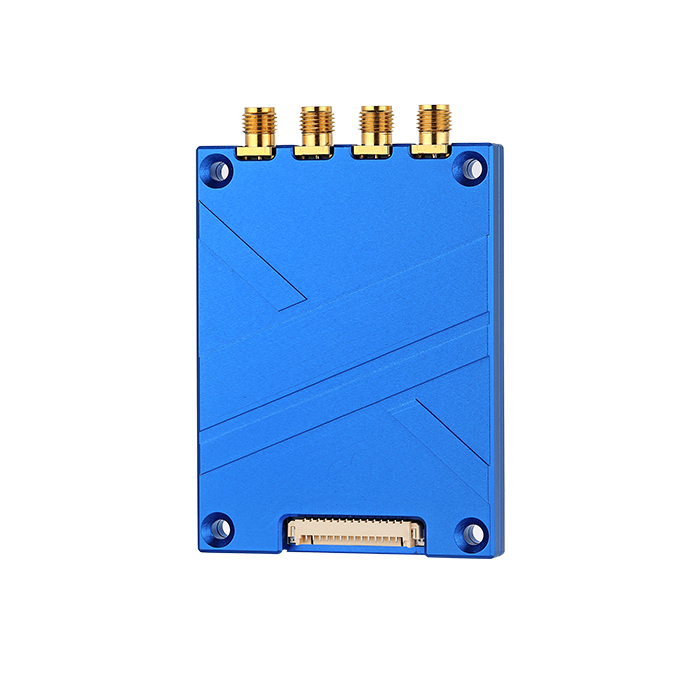

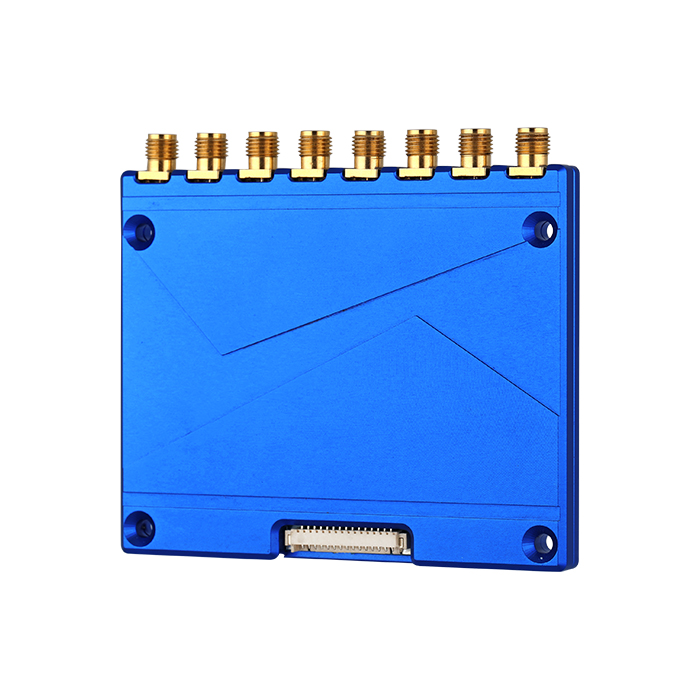

HZ5808-port UHF RFID ModuleHZ580 UHF RFID module provides a wide power supply range (dc4.5v ~ 6V). This RFID reader module is configured GPIO interface (IO1-IO4, IO1 / IO2 as input and IO3 / IO4 as output). Its frequency range is from 840MHz to 960MHz. Users can easily communicate with their own equipment through UART-TTL pin on the interface of HZ580 UHF RFID module.Details

-

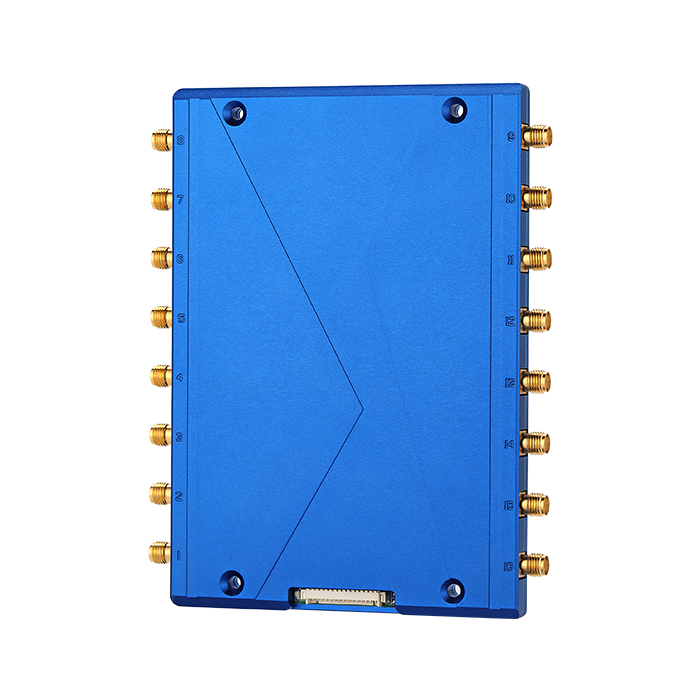

HZ53016-Port UHF RFID ModuleHZ530 16-Port UHF RFID Module is specialized module for developing 16-port fixed RFID reader and Smart RFID cabinet system. Based on Impinj R2000 chip platform, with 16 channels of SMA interfaces for RFID antennas, it support multiple-tag and long range reading.Details

-

HL7205G9dBi Long Range UHF RFID AntennaIt has the characteristics of thin thickness, low standing wave and good circular polarization. This antenna is a general-purpose antenna, suitable for use in medium-distance indoor environments.Details