High Performance, Humanized Design

Features

-

Fixed/hop frequency optional

Fixed/hop frequency optional -

Support RSSI, antenna detection, online update

Support RSSI, antenna detection, online update -

Support RSSI & Data filtering

Support RSSI & Data filtering -

Support Anti-collision algorithm

Support Anti-collision algorithm

Highlights

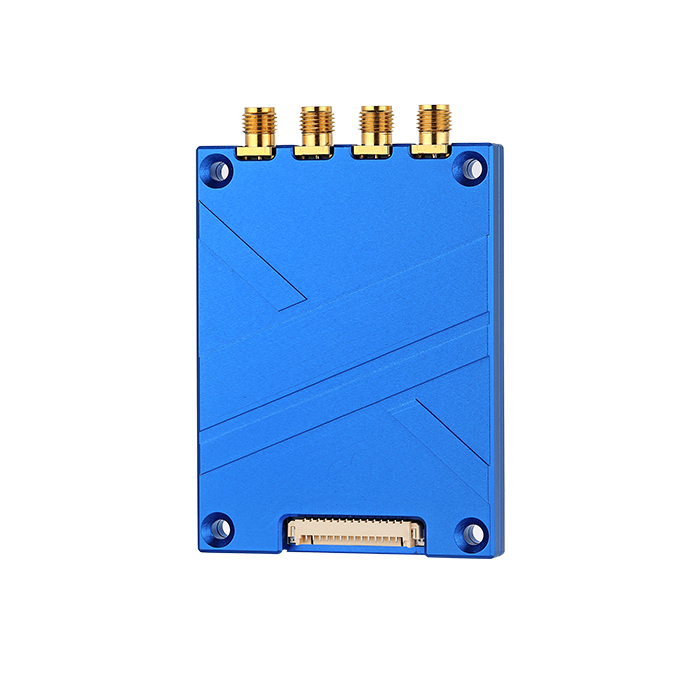

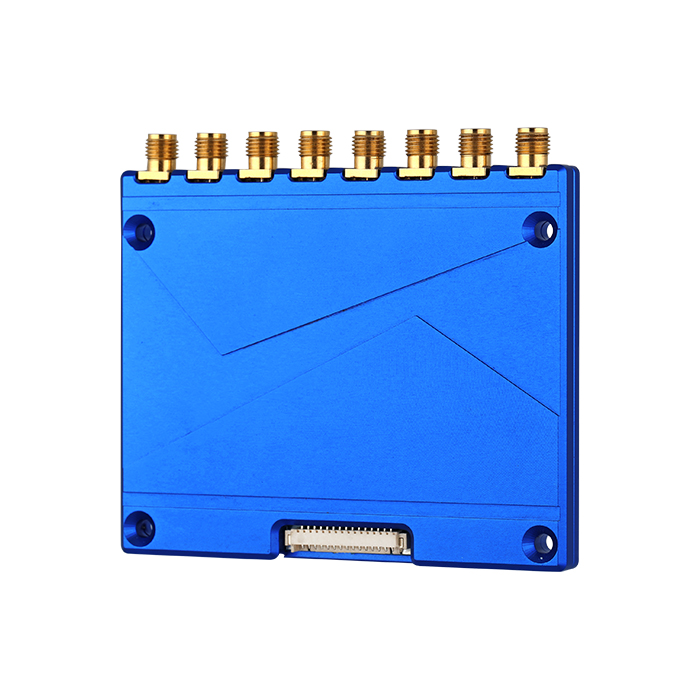

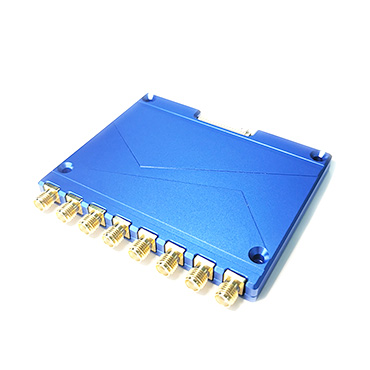

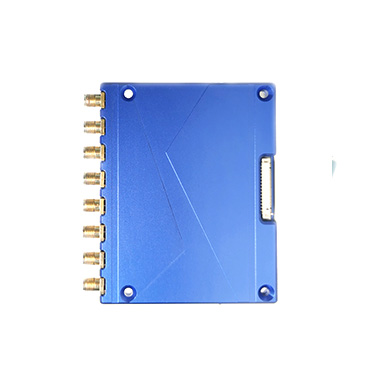

Hopeland HZ580 is the UHF RFID reader module board for developing 8-port fixed RFID reader, which is meant for OEM and developers to embed into products or to be used in the creation of a new 8-port RFID reader. With high integration and superb performance, this UHF RFID reader module is ideal for industries like bank collateral management, smart retail and warehousing.

Excellent extensibility, high output power, high sensitivity, low power consumption

Specifications

-

Physical

Dimension 78.55mm×88mm×7.85mm RF Connector SMA-Female*8 Communication Interface TTL UART serial Interface Cable 12P 1.0mm pitch FFC cable -

Electrical

Operating Voltage +4.5V~+5.5V Standby Current < 20mA Operating Current 5V power supply, 5

1100mA @ +30dBm, working peak current is about 1500mA -

RFID

Chipset Indy R2000 Air Protocal ISO/IEC 18000-6B,ISO/IEC 18000-6C/EPC C1G2/ C2G2 Frequency FCC 902MHz~928MHz,GB 920MHz~925MHz,ETSI 865MHz~868MHz,

Japan Korea Malaysia Taiwan etc.Receive Sensitivity ≤-80dBm Output Power 0~33dBm(±1dB)adjustable -

Environmental

Operating Temperature 25℃~﹢70℃ Storage Temperature ﹣45℃~﹢85℃ Operating humidity <95% (﹢25℃)

Applications

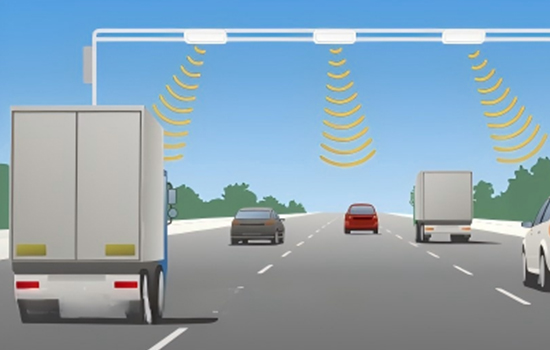

Warehousing & Logistics

Smart Warehousing

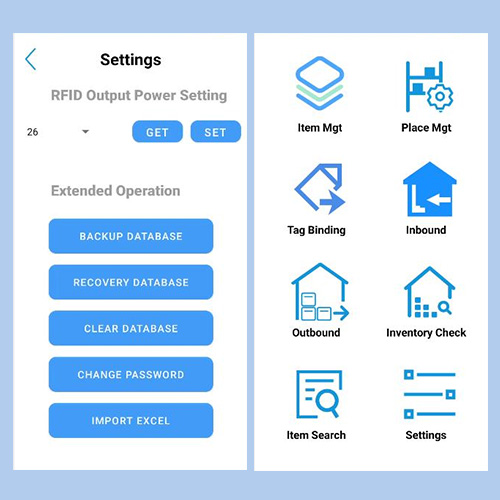

Modern warehouse storage is not only to complete the simple batch processing of goods in and out, but also to make clear database records of the types, quantities, production attributes, stacking positions and other information of goods in the warehouse. In order to obtain accurate product data and supply chain information at all stages of the logistics chain.

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

View Details

Asset Management

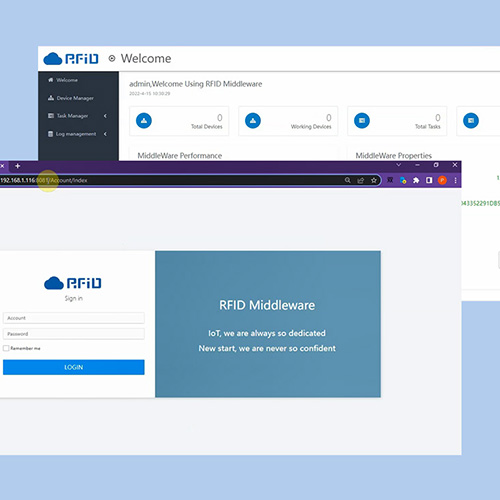

Bank Collateral Management

1. Using RFID technology, intelligent inventory cabinets and control programs, a timed inventory strategy can be formulated, and the system can automatically complete the inventory at a specified time without manual intervention; the inventory results are fed back in real time;

2. Support the remote and unannounced inspections of tier-2 branches by tier-1 branches, trigger remote monitoring at any time, and conduct physical inventory from time to time;

3. The physical inventory data is automatically synchronized with the accounting data of the accounting system to achieve automatic daily reconciliation to ensure that the accounts are consistent.

2. Support the remote and unannounced inspections of tier-2 branches by tier-1 branches, trigger remote monitoring at any time, and conduct physical inventory from time to time;

3. The physical inventory data is automatically synchronized with the accounting data of the accounting system to achieve automatic daily reconciliation to ensure that the accounts are consistent.

View Details

Smart Retail

RFID Smart Refrigerator

With the rising cost of human resources and the increasing demand for the ultimate shopping experience, consumers are more comfortable with access to food and beverages anytime and anywhere. This has led to the emergence of smart new retail methods such as unmanned convenience stores, smart refrigerators, and smart vending machines. Among them, unmanned vending machines are one of the most common ones in daily life.

At same time, retail companies need to track all goods inventory status, improve operational efficiency, save labor cost and analysis customer's purchase trend to increase revenue. RFID technology can help them achieve it effortlessly. Nowadays, RFID technology is widely used in retail. The automatic retail fridge is built with RFID UHF hardware, so that retailers can track the goods status at any time. More importantly, smart RFID refrigerators enable buyer to finish purchase process alone and automatically.

At same time, retail companies need to track all goods inventory status, improve operational efficiency, save labor cost and analysis customer's purchase trend to increase revenue. RFID technology can help them achieve it effortlessly. Nowadays, RFID technology is widely used in retail. The automatic retail fridge is built with RFID UHF hardware, so that retailers can track the goods status at any time. More importantly, smart RFID refrigerators enable buyer to finish purchase process alone and automatically.

View Details

Smart Retail

Smart Retail Store

Pain points in traditional retail stores

Operating aspects:

The operating costs of common convenience stores continue to rise

The cost of rent

convenience stores and merchants are more and more concerned with the capital. But the store resources are relatively scarce, and the pressure on the rising cost of rent will continue to exist in the future.

Labor costs

The decline of the working age workforce increases the labor cost. The increase of convenience store staff mobility and the increase of personnel costs and management costs.

The cost of water and electricity

The relative area is larger and the water power consumption is more.

Consumer aspects:

Purchasing daily necessities is inconvenient and far away.

There is no 24-hour store in the evening, and difficult to meet any emergency.

Operating aspects:

The operating costs of common convenience stores continue to rise

The cost of rent

convenience stores and merchants are more and more concerned with the capital. But the store resources are relatively scarce, and the pressure on the rising cost of rent will continue to exist in the future.

Labor costs

The decline of the working age workforce increases the labor cost. The increase of convenience store staff mobility and the increase of personnel costs and management costs.

The cost of water and electricity

The relative area is larger and the water power consumption is more.

Consumer aspects:

Purchasing daily necessities is inconvenient and far away.

There is no 24-hour store in the evening, and difficult to meet any emergency.

View Details

Send A Message

Related Products

-

HF100New 2-port Integrated RFID readerNew Sharp series Linux Super long reading Integrated RFID reader - HF100 2-port version integrated RFID reader is one of series Hopeland Fixed RFID Reader, integrated design but support 1 additional antenna port. Running with Impinj Indy R2000 chipset/ newest Impinj E710 RAIN RFID reader chip upgradable, and operated on Linux 2.6 operation system. It not only includes built-in 4G, WiFi, and Bluetooth, and PoE (IEEE 802.3 af/at/bt) optional, but also supports built-in web management functions such as remote parameter configuration, MQTT, HTTP post, MySQL database transferring and so on.Details

-

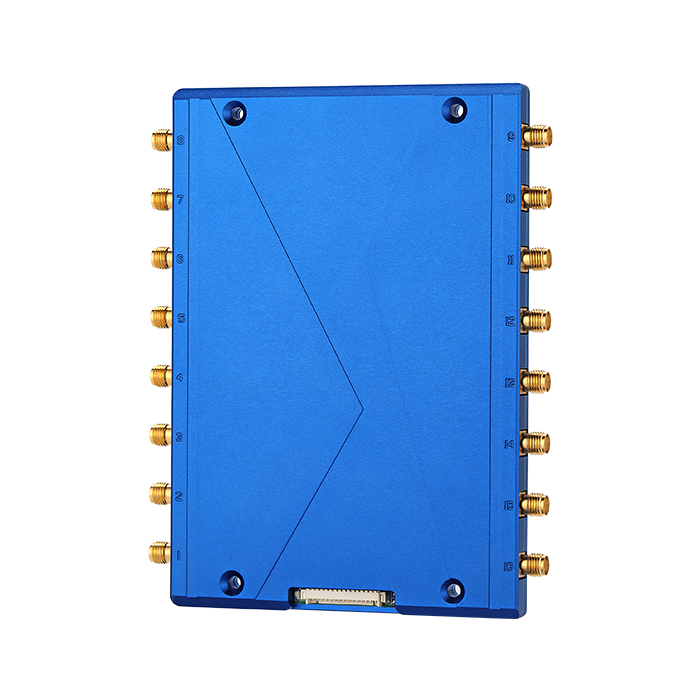

HZ53016-Port UHF RFID ModuleHZ530 16-Port UHF RFID Module is specialized module for developing 16-port fixed RFID reader and Smart RFID cabinet system. Based on Impinj R2000 chip platform, with 16 channels of SMA interfaces for RFID antennas, it support multiple-tag and long range reading.Details

-

HL7205G9dBi Long Range UHF RFID AntennaIt has the characteristics of thin thickness, low standing wave and good circular polarization. This antenna is a general-purpose antenna, suitable for use in medium-distance indoor environments.Details

-

HZ340Cost-effective 4 Ports ReaderCost-effective multi-port fixed UHF RFID reader, supports ISO18000-6C/6B protocols, output power 0 ~ 30dBm optional, with high recognition sensitivity, fast speed, strong anti-interference ability , Multi-antenna identification efficiency.Details