Features

-

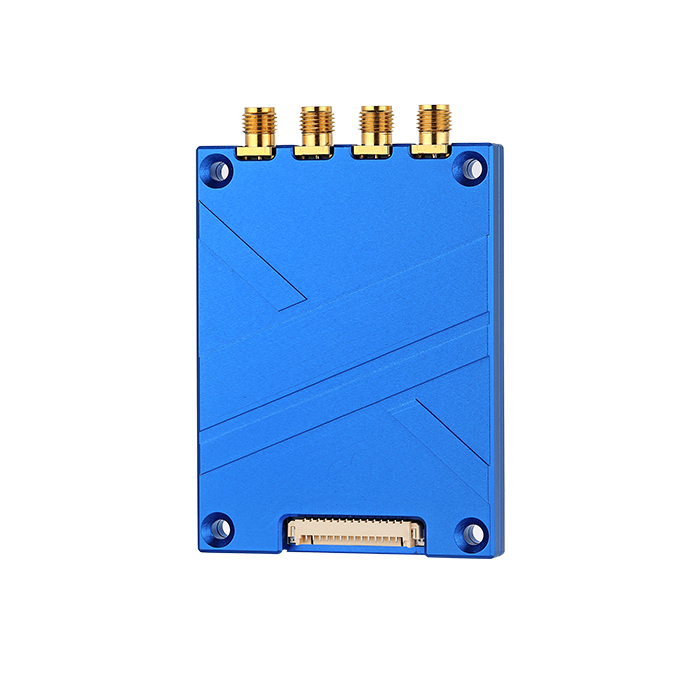

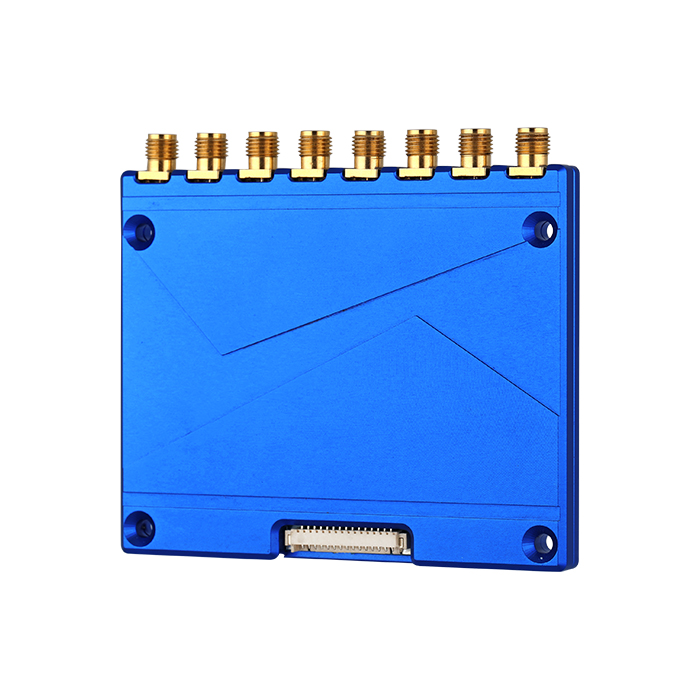

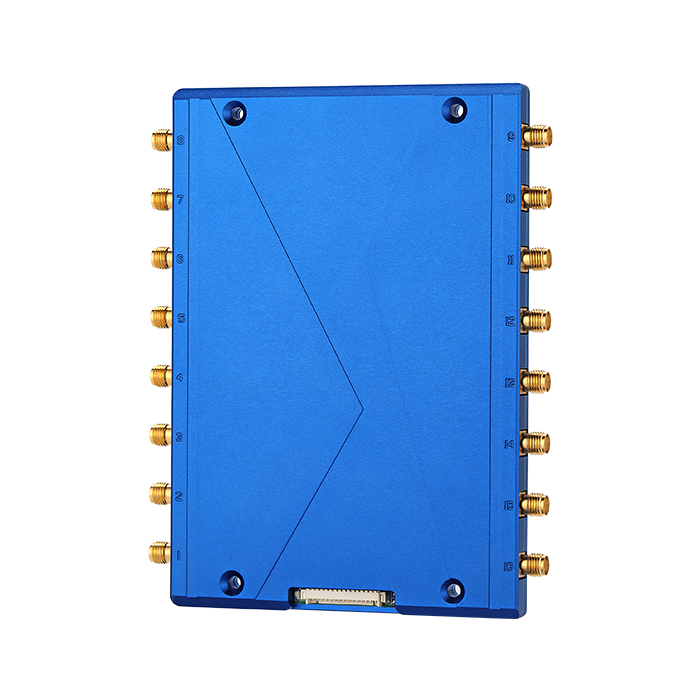

Rich communication interfaces: RS232/RS485

Rich communication interfaces: RS232/RS485 -

Reading distance:0~120mm

Reading distance:0~120mm -

Support online and remote upgrade

Support online and remote upgrade -

Support reading indicator

Support reading indicator

Highlights

Support protocol: ISO15693/ISO14443A

Rich communication interfaces: RS232/RS485

Support Modbus RTU/Own instruction protocol double protocol

Working mode: instruction automatic reading/automatic reading optional

Support online and remote upgrade

Support reading indicator

Specifications

Applications

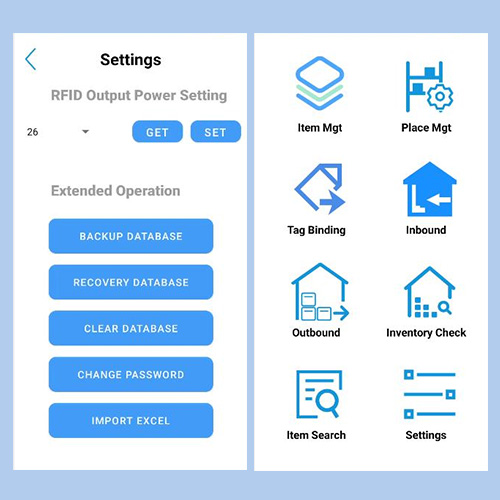

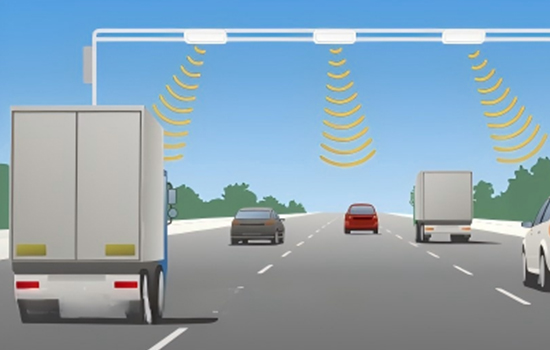

Warehousing & Logistics

Smart Warehousing

Modern warehouse storage is not only to complete the simple batch processing of goods in and out, but also to make clear database records of the types, quantities, production attributes, stacking positions and other information of goods in the warehouse. In order to obtain accurate product data and supply chain information at all stages of the logistics chain.

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

View Details

Industry 4.0

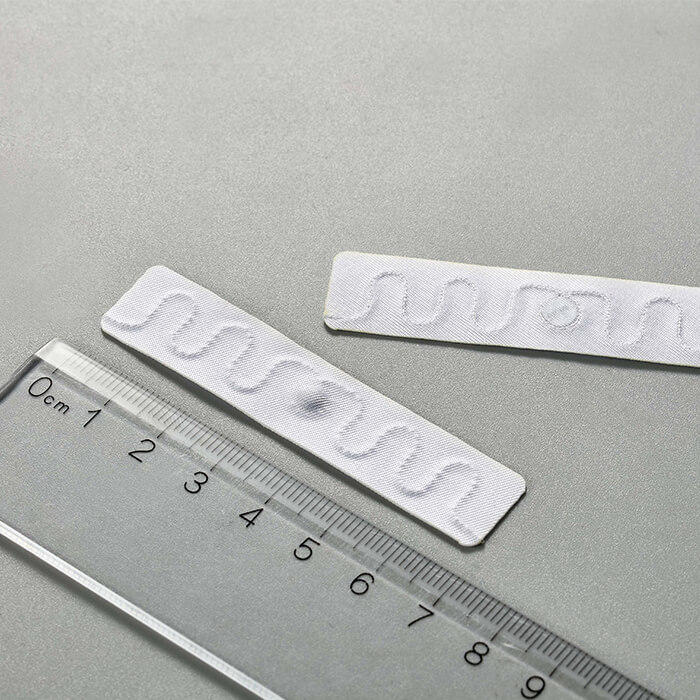

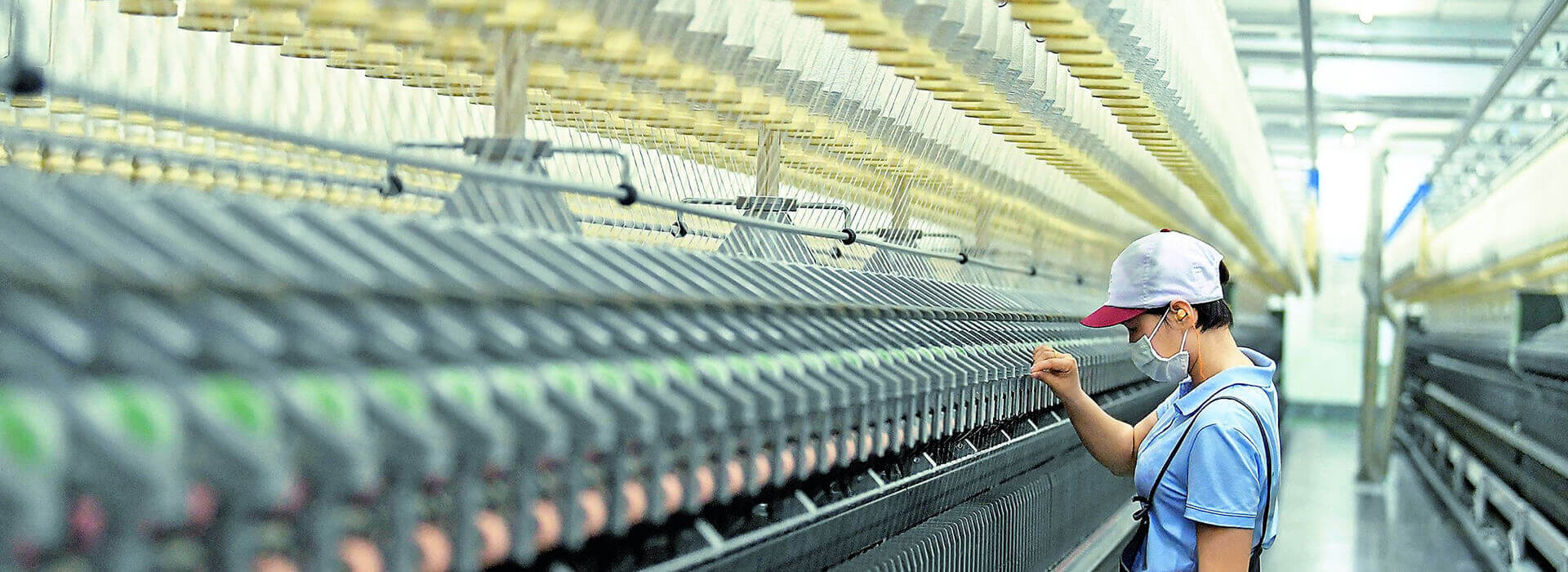

Textile Production

At present, bar code scanners are used to scan the labels outside the box one by one in the weaving and weaving yarn bins and winding in and out warehouses. The average daily scanning time is more than 28 hours and the workload is large, which wastes a lot of manpower and is not efficient.

The modern warehouse management system based on RFID technology can automatically complete the scanning of multiple labels at one time, save time and manpower, effectively achieve the accuracy of inventory, detect idle weft yarns in time, and improve the efficiency of management weft allocation. Cooperate with automatic assembly line, AGV, manipulator and other equipment, use RFID technology to intelligently perceive equipment and materials, realize production automation, real-time and visualize warehouse management, and use special mobile terminals to achieve fast and accurate inventory. The successful implementation of the project will provide strong support for the information process of the subsequent automated allocation warehouse.

The modern warehouse management system based on RFID technology can automatically complete the scanning of multiple labels at one time, save time and manpower, effectively achieve the accuracy of inventory, detect idle weft yarns in time, and improve the efficiency of management weft allocation. Cooperate with automatic assembly line, AGV, manipulator and other equipment, use RFID technology to intelligently perceive equipment and materials, realize production automation, real-time and visualize warehouse management, and use special mobile terminals to achieve fast and accurate inventory. The successful implementation of the project will provide strong support for the information process of the subsequent automated allocation warehouse.

View Details

Asset Management

Tool Management Solutions

Traditional tool management methods generally rely on non-automated, paper-based systems to record, track and manage; a few use barcodes to identify and manage assets; but the efficiency is extremely low, with the increase in the number of assets, extremely The earth has increased the burden of management personnel, a serious waste of human resources, and also increased the difficulty of tool management, often resulting in untimely data and high error rates. Often the inventory management is chaotic, and the inbound and outbound data is wrong. If it is left to exist on a large scale for a long time, it will bring great cost problems to the enterprise.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

View Details

Send A Message

Related Products

-

HH100Android Integrated RFID readerNew Shine serie - Android Integrated RFID reader HH100 Smart IoT device with integrated design but support 1 additional antenna port. Running with Impinj Indy R2000 chipset/ newest Impinj E710 RAIN RFID reader chip upgradable, and operated on Otca-core Android 9.0 operation system. It not only includes built-in 4G, WiFi, and Bluetooth as standard, and PoE (IEEE 802.3 af/at/bt) optional, but also supports built-in web management functions such as remote parameter configuration, MQTT, HTTP post, MySQL database transferring and so on.Details

-

Smart HZ100Parking System Integrated RFID ReaderHigh performance Integrated UHF RFID reader HZ100, updated from CL7206B5A, supporting ISO18000-6C protocol, long range RFID reading, fast identification, excellent multi-tag reading, strong Anti-collision, automatic reading, white list functions. Widely used fixed asset management, logistic, warehouse inventory, products tracking transshipment , e parking system vehicle management, production automation etc.Details

-

S120USB RFID Desktop Reader/WriterS120 is a convenient desktop RFID reader&writer, portable with small size, fit for production line and work station management, access control, library management. It's widely used for tag's reading, writing, authorizing and format operation.Details

-

HF100New 2-port Integrated RFID readerNew Sharp series Linux Super long reading Integrated RFID reader - HF100 2-port version integrated RFID reader is one of series Hopeland Fixed RFID Reader, integrated design but support 1 additional antenna port. Running with Impinj Indy R2000 chipset/ newest Impinj E710 RAIN RFID reader chip upgradable, and operated on Linux 2.6 operation system. It not only includes built-in 4G, WiFi, and Bluetooth, and PoE (IEEE 802.3 af/at/bt) optional, but also supports built-in web management functions such as remote parameter configuration, MQTT, HTTP post, MySQL database transferring and so on.Details