Overview

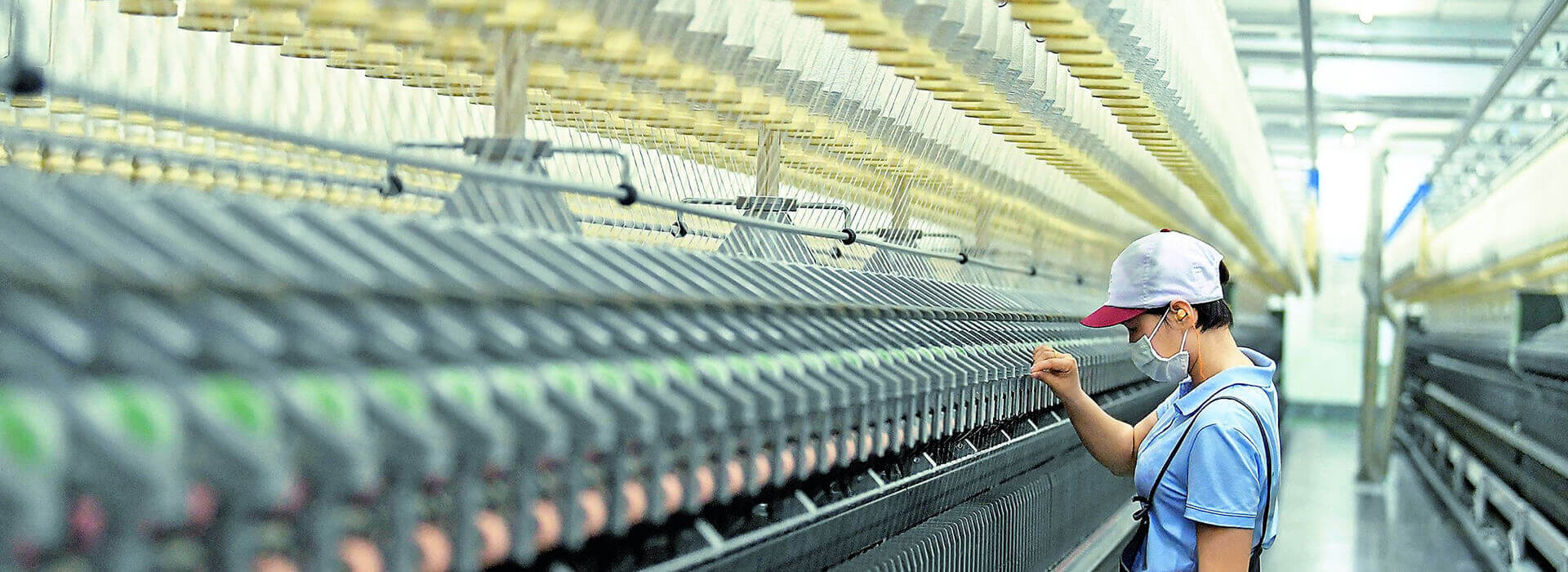

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

Purpose

- Improve the warehousing efficiency of finished products, and set up RFID channel gates at the entrances and exits of finished products, which can realize the simultaneous and automatic reading of the warehousing information of one or more batches of finished products, which greatly improves the efficiency of information collection and reduces the probability of manual errors. .

- Real-time management of finished products and cargo positions within the warehouse, marking the cargo positions with RFID tags and storing them in the information system, and automatically assigning cargo positions through the system during the process of entering and leaving the warehouse or moving the finished products, and through the forklift on-board computer It can automatically identify and match the cargo space information with the RFID identification equipment to guide the forklift driver to carry out the operation of entering and leaving the warehouse. After the operation is completed, the information of the system is automatically and real-time updated.

- Reduce the work intensity of workers in the outbound link, reduce the probability of errors, and realize the automatic processing of most of the work links through RFID technology, completely changing the current status of workers holding paper outbound orders to find the cargo space, and satisfying the speed of the outbound link to the greatest extent. , accurate requirements.

Solution

The system is divided into four layers from bottom to top, namely physical operation layer, acquisition and interaction layer, RFID data service layer, and enterprise application layer:

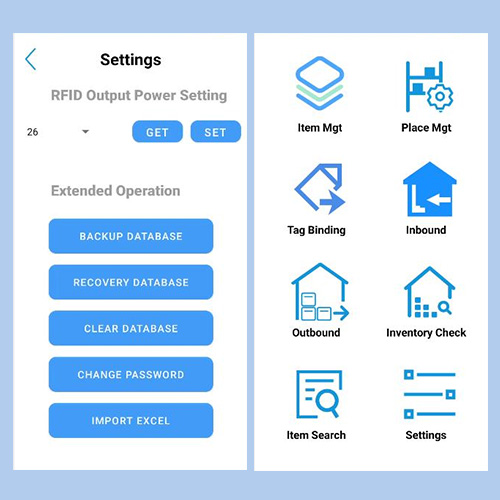

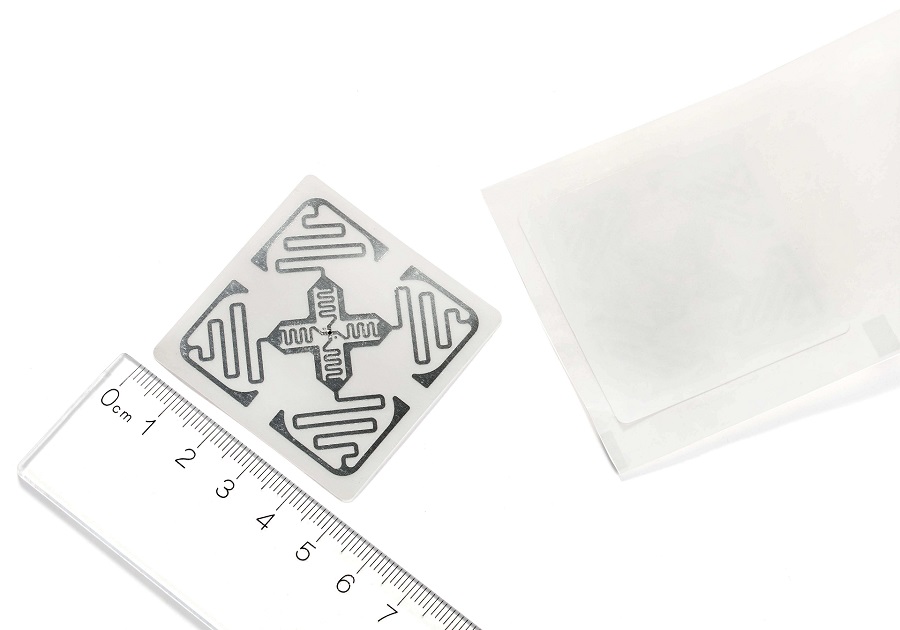

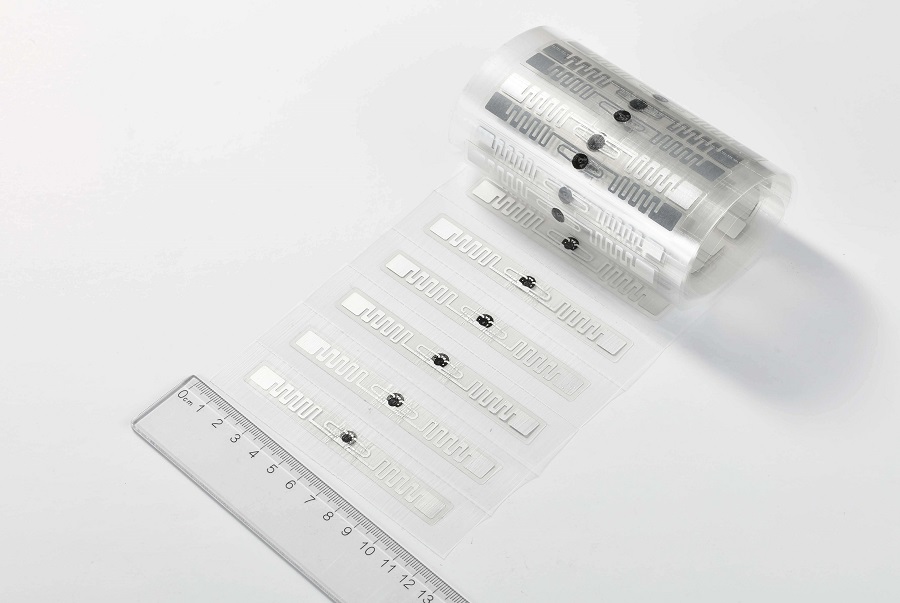

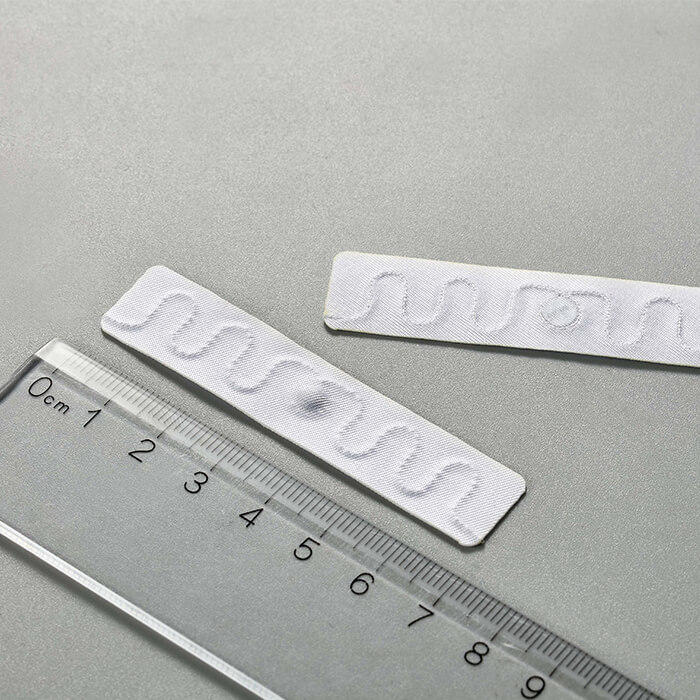

Physical operation layer: The physical layer of the warehouse includes warehouses, warehouse areas, three-dimensional shelves/flat warehouses, warehouse locations, containers, forklifts, on-site operations, etc. On-site operations include warehousing, warehousing, inventory, picking, warehouse transfer, warehouse transfer, etc. All valid storage locations and cargo boxes in the warehouse require the installation of RFID electronic tags to achieve refined management of individual storage locations and cargo boxes.

Data acquisition layer: Contains various on-site data acquisition and user interaction equipment, including RFID handheld terminals, RFID fixed readers, RFID vehicle readers, forklift vehicle computers, wireless barcode scanners with RFID reading functions, etc. It mainly provides user operation guidance, on-site data collection, data entry, etc. Provide real-time on-site data collection and interactive operation guidance for the system.

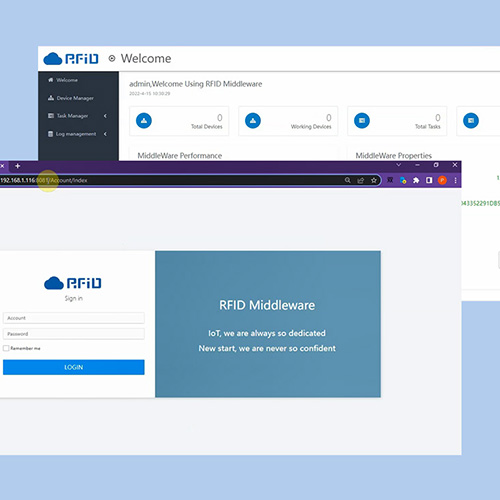

RFID data service layer: manage the RFID equipment and related equipment in the system, collect, cache, filter the collected data, collect and distribute control instructions and related data, etc. The data service layer runs on the system server in the form of system software service, and provides data services for the RFID data and related control instructions of the user application layer and the data acquisition and interaction layer.

Advantages

1) Improve warehouse management accuracy, management accuracy and convenience of operation

Using the most advanced RFID technology and the existing local area network to form a management network to monitor the flow of materials in the warehouse in real time;

2) Improve enterprise efficiency

With the assistance of RFID technology, two electronic tags of cargo packaging and cargo location are used for warehouse management;

3) Realize refined inventory management

There is a unique representation for the smallest packaging unit;

4) Improve the accuracy of entering, exiting, storing and moving

Reduce the dependence on people in daily work and reduce human errors; record the records of various parts and components in storage, the number of in and out, and the location, etc., and record the part change information (type, quantity, etc.) in the warehouse label to track the warehouse. goods;

5) Assist in purchasing to make order planning

The entry and exit of parts and components correspond to the location label, and the inventory of each specification material corresponding to the corresponding location is accurately recorded;

6) It is convenient for quick positioning of goods

In the management of moving warehouses and warehouses, warehouse personnel can quickly locate the goods according to the electronic labels and automatically adjust the positions in the system;

7) Improve inventory efficiency

In the inventory count, it is separated from the documents to improve the inventory efficiency, not only the inventory quantity but also the location, and ensure the correct rate of the goods and the location (storage), and can carry out regional inventory at any time in peacetime to ensure the correct inventory in daily warehouse work, In particular, the inventory work can be carried out when the access is normal.

Related Devices

-

HY820UHF RFID handheld terminalImpinj E710 Supportable,UHF 25M Read Range;Industrial IP65 Rugged,1.5M Drop Test,Suitable For Different Harsh EnvironmentRead More

-

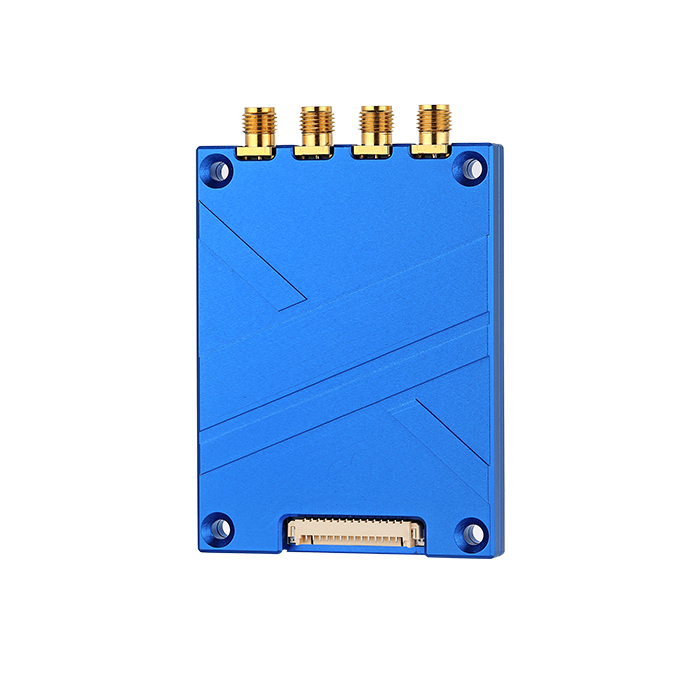

HF3808 Ports Fixed ReaderIMPINJ RAIN RFID E710 high-performance RFID chip; built-in Linux, easy to customize application development; can support POE power supply

at maximum power; expandable Bluetooth, WiFi wireless transmission function; support RJ-45/RS-232/RS-485 /USB/Wiegand multiple

communication interfaces; support remote configuration via Web.Read More -

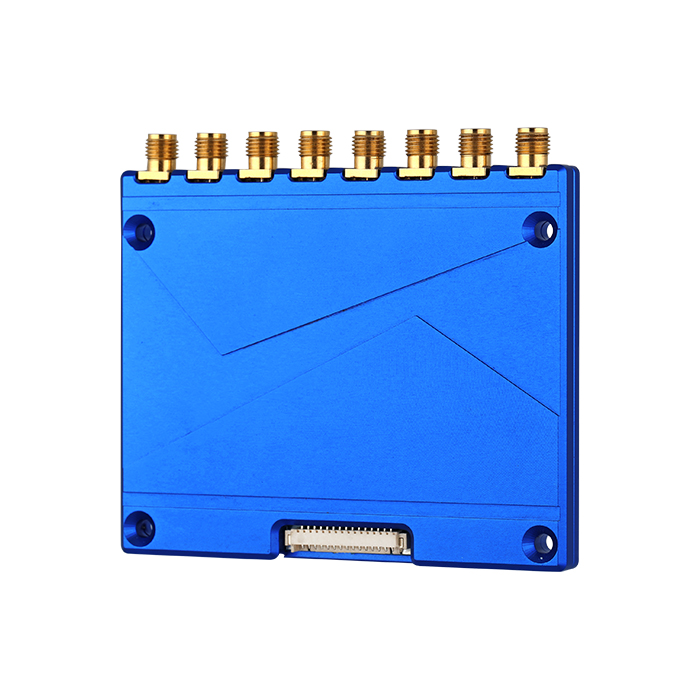

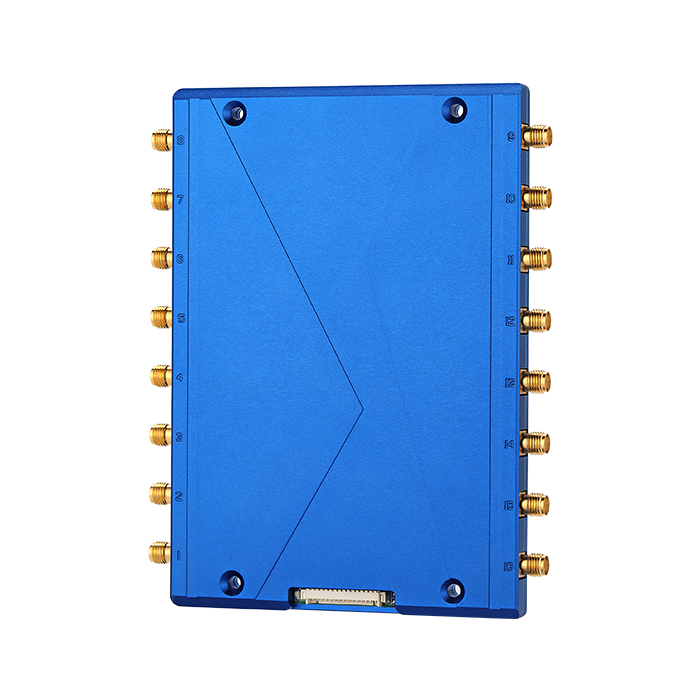

HF3404 Ports Fixed ReaderAdopt Impinj R2000/E710 chip platform; Built-in Linux system; Super long reading distance up to 30meters and 600-900 times each second. Kinds of communication interfaces: RJ45, RS485, Wiegand, USB, Wireless Wi-Fi, Bluetooth, 4G, PoE optional.Support RSSI, antenna detection, online update.Read More

-

HL7205G9dBi Long Range UHF RFID AntennaIt has the characteristics of thin thickness, low standing wave and good circular polarization. This antenna is a general-purpose antenna, suitable for use in medium-distance indoor environments.Read More

Related Solution