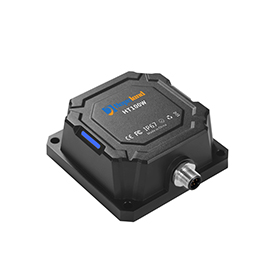

HF Industrial Integrated Reader

Features

-

Powered by ST25R3916 RF scheme

Powered by ST25R3916 RF scheme -

Support RS485 / RS232 interface

Support RS485 / RS232 interface -

Support Modbus RTU & Hopeland command protocol (Dual Protocols)

Support Modbus RTU & Hopeland command protocol (Dual Protocols) -

Support automatic tag reading mode / Command tag reading mode

Support automatic tag reading mode / Command tag reading mode

Highlights

Specifications

-

Performance parameter

Air Protocols ISO15693, ISO14443A Features Support online upgrade

Support tag reading indicatorsWork Mode Automatic tag reading mode / Command tag reading mode Working frequency 13.56Mhz Reading speed ≥100times/s Reading Distance 0m~100mm(According to Tag & Environment) Interface RS232:115200bps(default)

RS485:115200bps(default) -

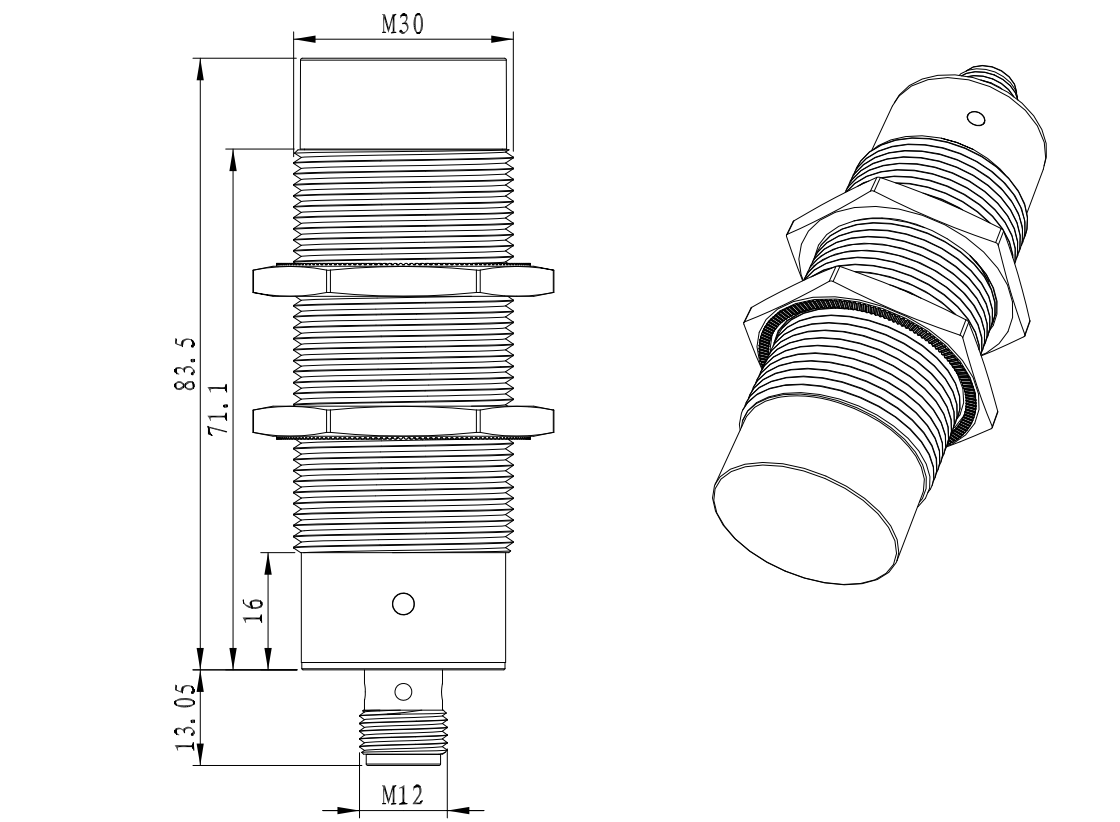

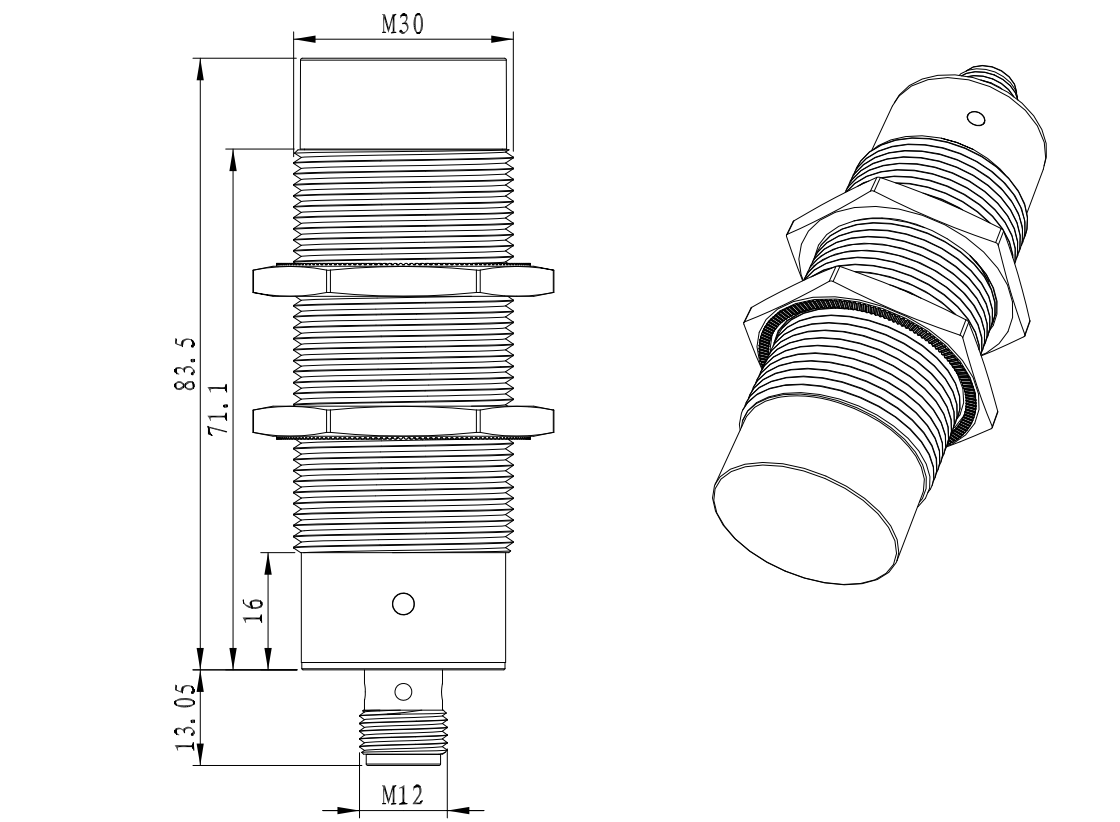

Physical parameter

Power Supply Power Supply 12~24V Power Consumption ≤1.35W Standby Power ≤0.65W Operating Temp. -25 - +80°C Storage Temp. -40 - +85°C Humidity 0%RH-95%RH non-condensing (+25℃) Atmospheric pressure 86kPa~108kPa Sealing IP67

Applications

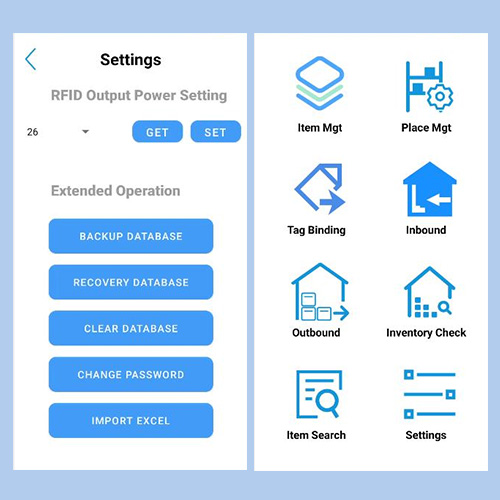

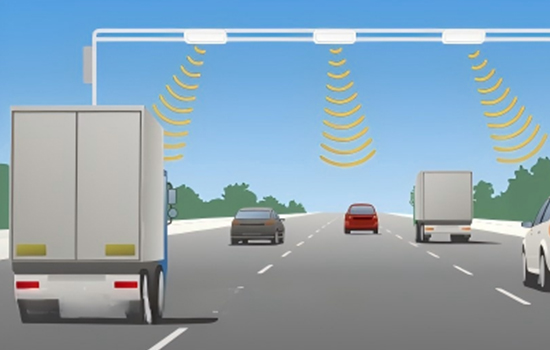

Warehousing & Logistics

Smart Warehousing

Modern warehouse storage is not only to complete the simple batch processing of goods in and out, but also to make clear database records of the types, quantities, production attributes, stacking positions and other information of goods in the warehouse. In order to obtain accurate product data and supply chain information at all stages of the logistics chain.

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

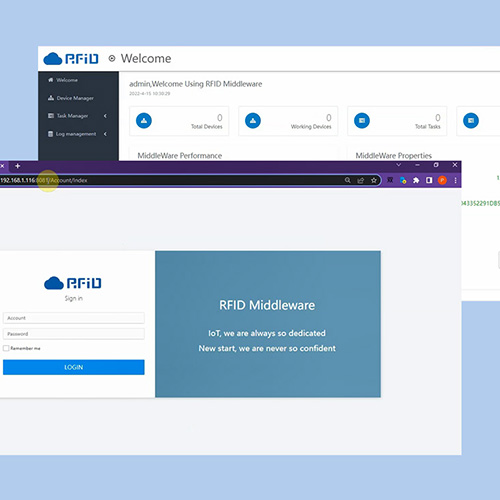

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

View Details

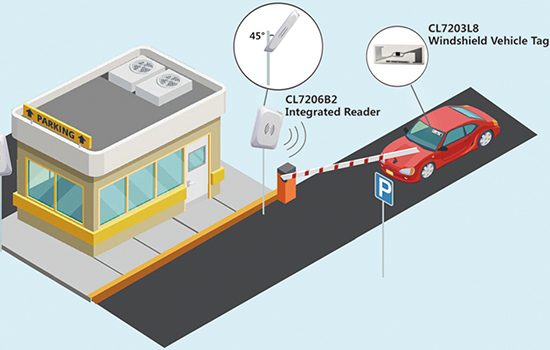

Asset Management

Tool Management Solutions

Traditional tool management methods generally rely on non-automated, paper-based systems to record, track and manage; a few use barcodes to identify and manage assets; but the efficiency is extremely low, with the increase in the number of assets, extremely The earth has increased the burden of management personnel, a serious waste of human resources, and also increased the difficulty of tool management, often resulting in untimely data and high error rates. Often the inventory management is chaotic, and the inbound and outbound data is wrong. If it is left to exist on a large scale for a long time, it will bring great cost problems to the enterprise.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

View Details

Send A Message

Related Products

-

S120USB RFID Desktop Reader/WriterS120 is a convenient desktop RFID reader&writer, portable with small size, fit for production line and work station management, access control, library management. It's widely used for tag's reading, writing, authorizing and format operation.Details

-

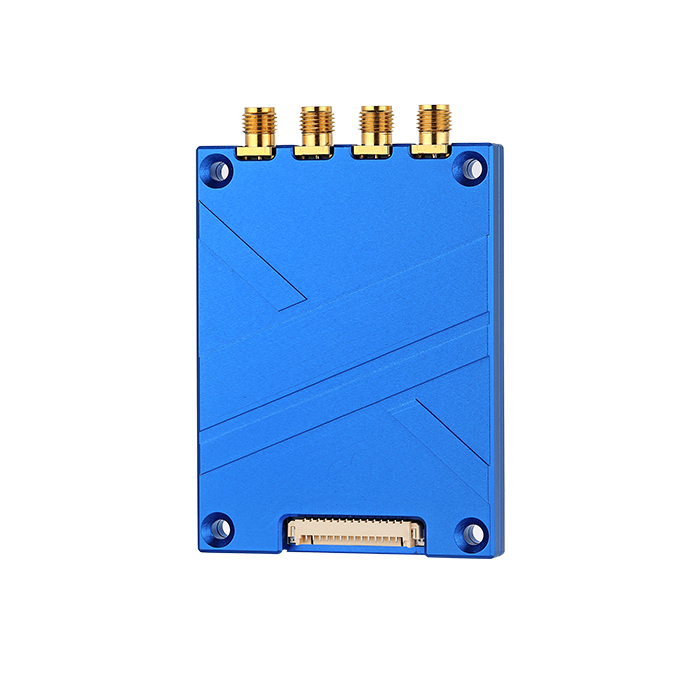

HZ5101-port UHF RFID ModuleHZ510 module is a miniaturized UHF RFID reading and writing module. The core component adopts R2000 as the core platform. R2000 is a high-performance and highly integrated reader and writer IC, which integrates the functions of analog RF front-end and baseband digital signal processing module.Details

-

HZ5404-port UHF RFID ModuleHZ540 module is a miniaturized UHF RFID reader. The core components of the core platform adopts R2000 which is a high-performance highly integrated reader IC and integrated with analog RF front-end and baseband digital signal processing modules etc.Details

-

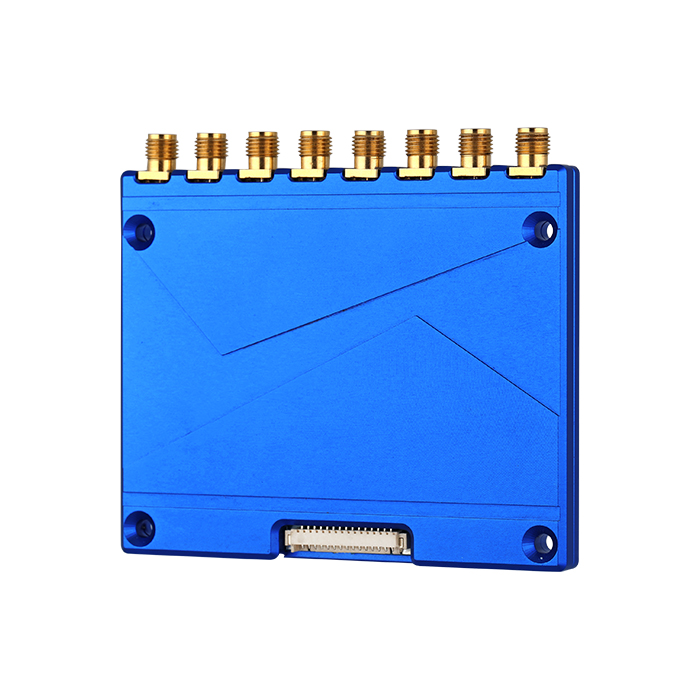

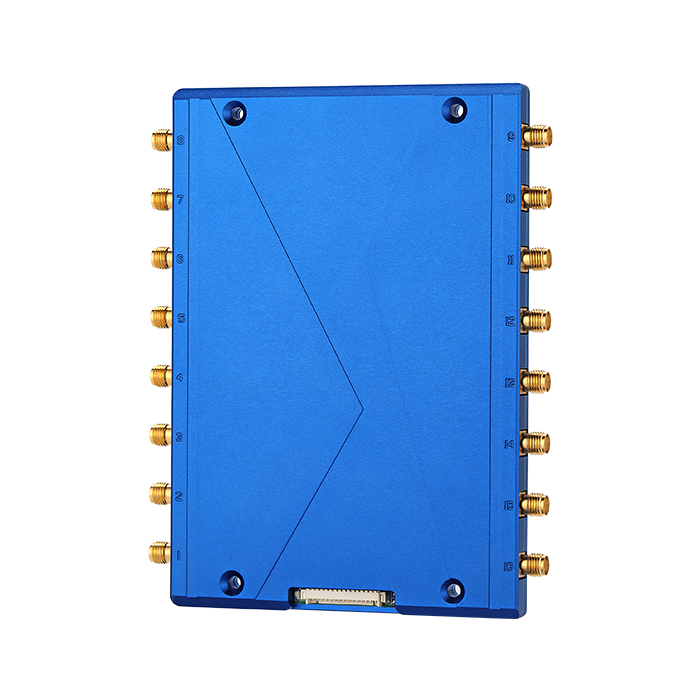

HZ5808-port UHF RFID ModuleHZ580 UHF RFID module provides a wide power supply range (dc4.5v ~ 6V). This RFID reader module is configured GPIO interface (IO1-IO4, IO1 / IO2 as input and IO3 / IO4 as output). Its frequency range is from 840MHz to 960MHz. Users can easily communicate with their own equipment through UART-TTL pin on the interface of HZ580 UHF RFID module.Details