UHF RFID Desktop Printer P113 - support metal tag

Features

-

Complete DLL, OCX and other SDK, complete Windows, Linux, Mac driver, make worry-free.

Complete DLL, OCX and other SDK, complete Windows, Linux, Mac driver, make worry-free. -

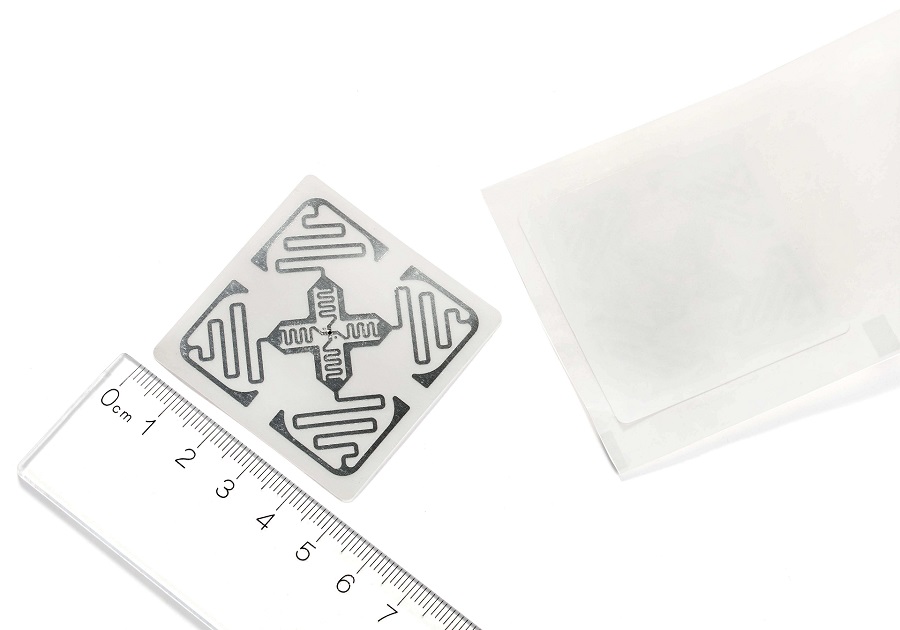

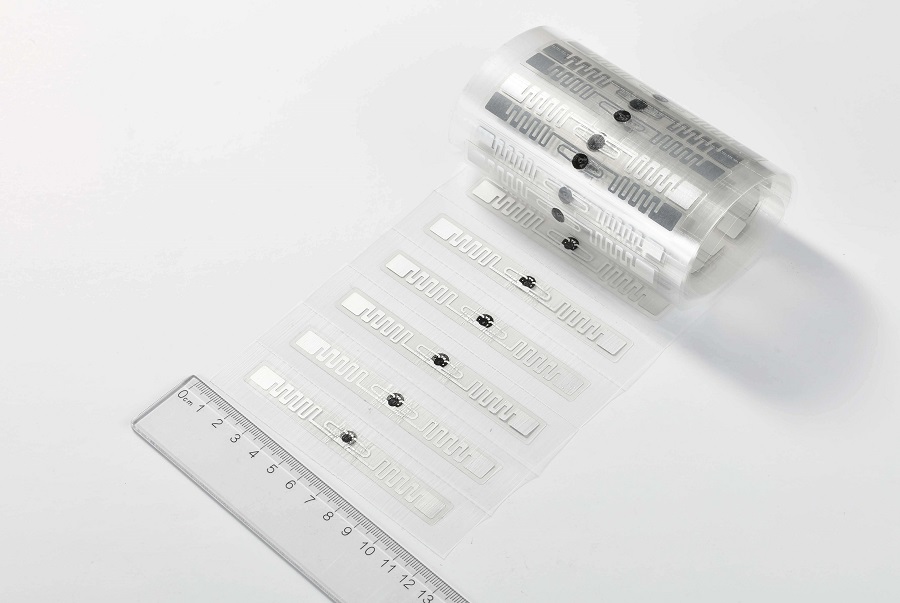

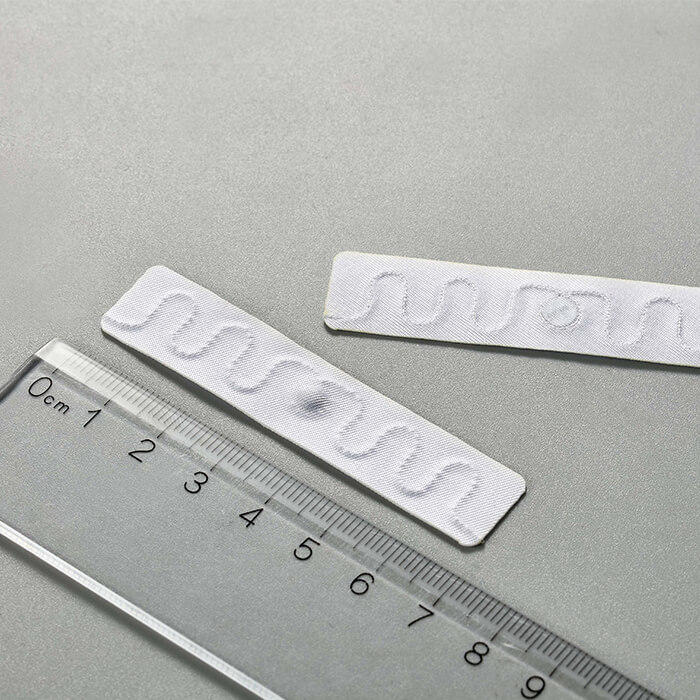

Support sense and print for RFID tags with different shapes and styles.

Support sense and print for RFID tags with different shapes and styles. -

Reasonable inner warehouse layout, very convenient for installation and replacement

Reasonable inner warehouse layout, very convenient for installation and replacement -

Accommodate up to 300 meters of ribbons and 5-inch label paper rolls

Accommodate up to 300 meters of ribbons and 5-inch label paper rolls -

300DPI printing speed, up to 6 inches per second realizes to save more working time

300DPI printing speed, up to 6 inches per second realizes to save more working time -

The combination of compactness and durability meets the needs of users who require small space and high-intensity printing in large quantities.

The combination of compactness and durability meets the needs of users who require small space and high-intensity printing in large quantities.

Highlights

Specifications

-

Parameters

Printing method Direct thermal & Thermal transfer Resolution 300 DPI (12dots/mm), 200DPI version optional Maximum print speed 6 IPS(152.4mm/s) Maximum print width 4.17″(106mm)

Maximum print length 78.7″(2000mm) Memory 8 MB Flash ROM, 16 MB SDRAM Media Roll-feed, die-cut, continuous, fan-fold, tags, tickets in plain paper or thermal paper

Width:4.6″(118mm) max.,0.8″(20mm)min.

Supply roll: OD 5″(127mm) max., ID 1″(25.4mm) min.

Thickness: 0.06~0.5mm (0.002″~0.02″), including linerRibbon Wax, Wax/Resin, Resin

Ribbon roll: OD 2.75″(70mm) max. with ID 1″(25.4mm) core or ID 0.5″(12.7mm) core

Max width: 110mm; Max length: 300MMedia sensor Adjustable reflective & Transmissive -

Physical

Bar Code Types 1D Barcode : Code 39,Code 93,Code 128,Codabar,EAN-8/13/128,Interleave

2 of 5,UCC-128,UPC A/E 2 and 5 add-on, etc.

2D Barcode: Data Matrix, MaxiCode, PDF417, QR, etc.Interfaces USB 2.0, RS232 Power rating 24 VDC, 2.0 A Weight 2.62KGS Dimensions W208 x D310 x H195 mm Operation environment Temperature: 32° F ~ +104° F (0° C ~ 40° C)

Relative humidity: 5% - 85% non condensingStorage environment

Temperature: -40° F ~ +140° F (-40° C ~ 60° C)

Relative humidity: 5% - 85% non condensingOptions RJ45 network card, peeler. Air Protocols ISO/IEC18000-6B, 6C / EPC C1Gen2 C2GEN2 optional Frequency USA: 902-928MHz (FCC part 15) / ETSI: 865-868MHz

CN: 920-925MHz (CMIIT)

Applications

Warehousing & Logistics

Smart Warehousing

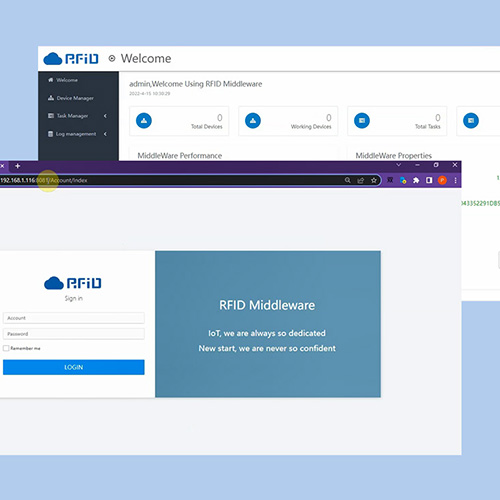

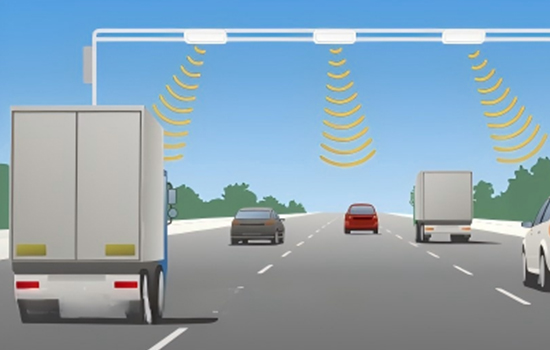

Modern warehouse storage is not only to complete the simple batch processing of goods in and out, but also to make clear database records of the types, quantities, production attributes, stacking positions and other information of goods in the warehouse. In order to obtain accurate product data and supply chain information at all stages of the logistics chain.

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

View Details

Asset Management

Tool Management Solutions

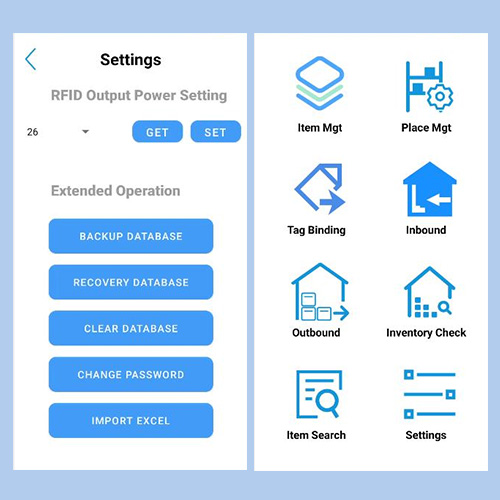

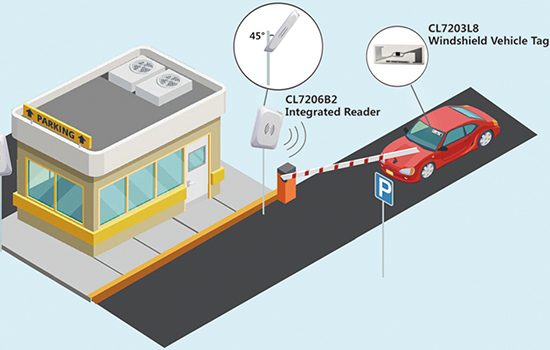

Traditional tool management methods generally rely on non-automated, paper-based systems to record, track and manage; a few use barcodes to identify and manage assets; but the efficiency is extremely low, with the increase in the number of assets, extremely The earth has increased the burden of management personnel, a serious waste of human resources, and also increased the difficulty of tool management, often resulting in untimely data and high error rates. Often the inventory management is chaotic, and the inbound and outbound data is wrong. If it is left to exist on a large scale for a long time, it will bring great cost problems to the enterprise.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

View Details

Send A Message

Related Products

-

HH100Android Integrated RFID readerNew Shine serie - Android Integrated RFID reader HH100 Smart IoT device with integrated design but support 1 additional antenna port. Running with Impinj Indy R2000 chipset/ newest Impinj E710 RAIN RFID reader chip upgradable, and operated on Otca-core Android 9.0 operation system. It not only includes built-in 4G, WiFi, and Bluetooth as standard, and PoE (IEEE 802.3 af/at/bt) optional, but also supports built-in web management functions such as remote parameter configuration, MQTT, HTTP post, MySQL database transferring and so on.Details

-

HF100New 2-port Integrated RFID readerNew Sharp series Linux Super long reading Integrated RFID reader - HF100 2-port version integrated RFID reader is one of series Hopeland Fixed RFID Reader, integrated design but support 1 additional antenna port. Running with Impinj Indy R2000 chipset/ newest Impinj E710 RAIN RFID reader chip upgradable, and operated on Linux 2.6 operation system. It not only includes built-in 4G, WiFi, and Bluetooth, and PoE (IEEE 802.3 af/at/bt) optional, but also supports built-in web management functions such as remote parameter configuration, MQTT, HTTP post, MySQL database transferring and so on.Details

-

HF3808 Ports Fixed ReaderIMPINJ RAIN RFID E710 high-performance RFID chip; built-in Linux, easy to customize application development; can support POE power supply

at maximum power; expandable Bluetooth, WiFi wireless transmission function; support RJ-45/RS-232/RS-485 /USB/Wiegand multiple

communication interfaces; support remote configuration via Web.Details -

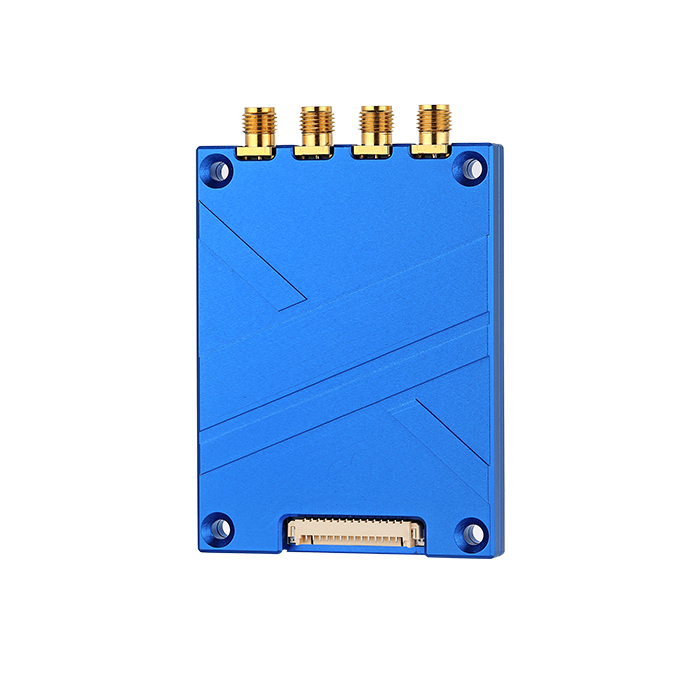

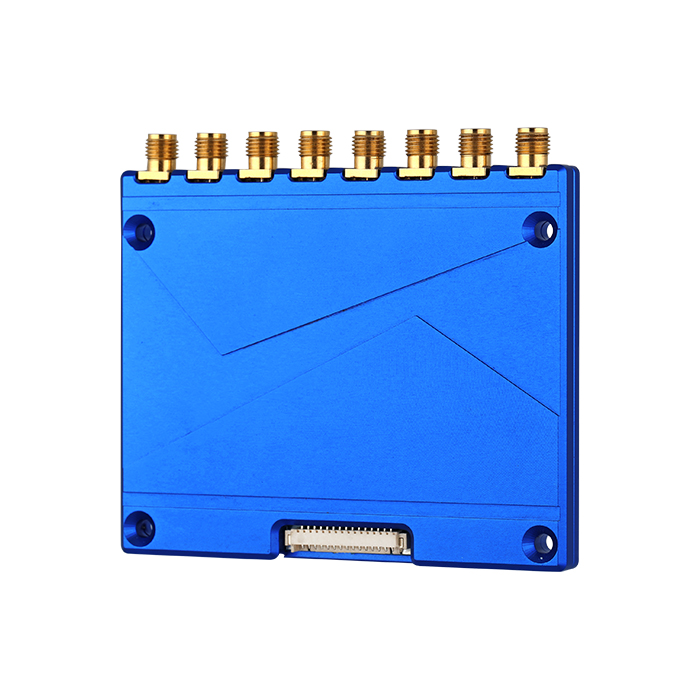

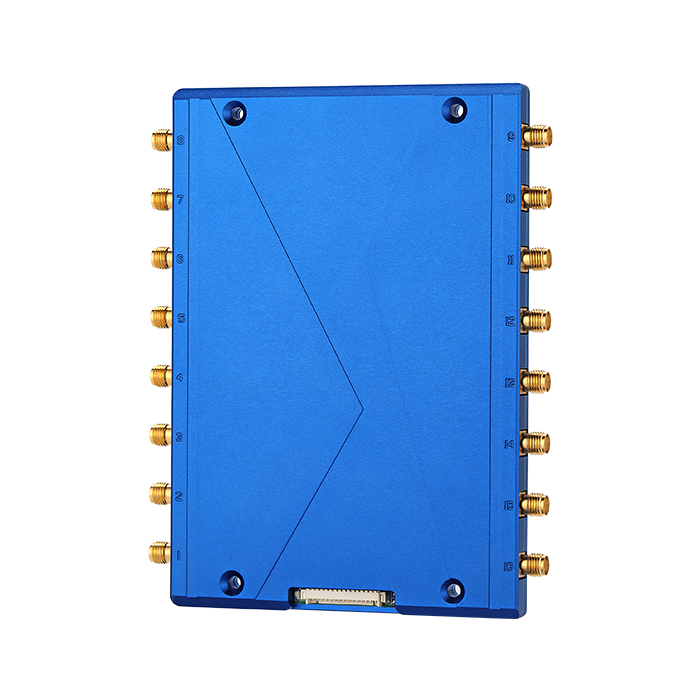

HZ5101-port UHF RFID ModuleHZ510 module is a miniaturized UHF RFID reading and writing module. The core component adopts R2000 as the core platform. R2000 is a high-performance and highly integrated reader and writer IC, which integrates the functions of analog RF front-end and baseband digital signal processing module.Details