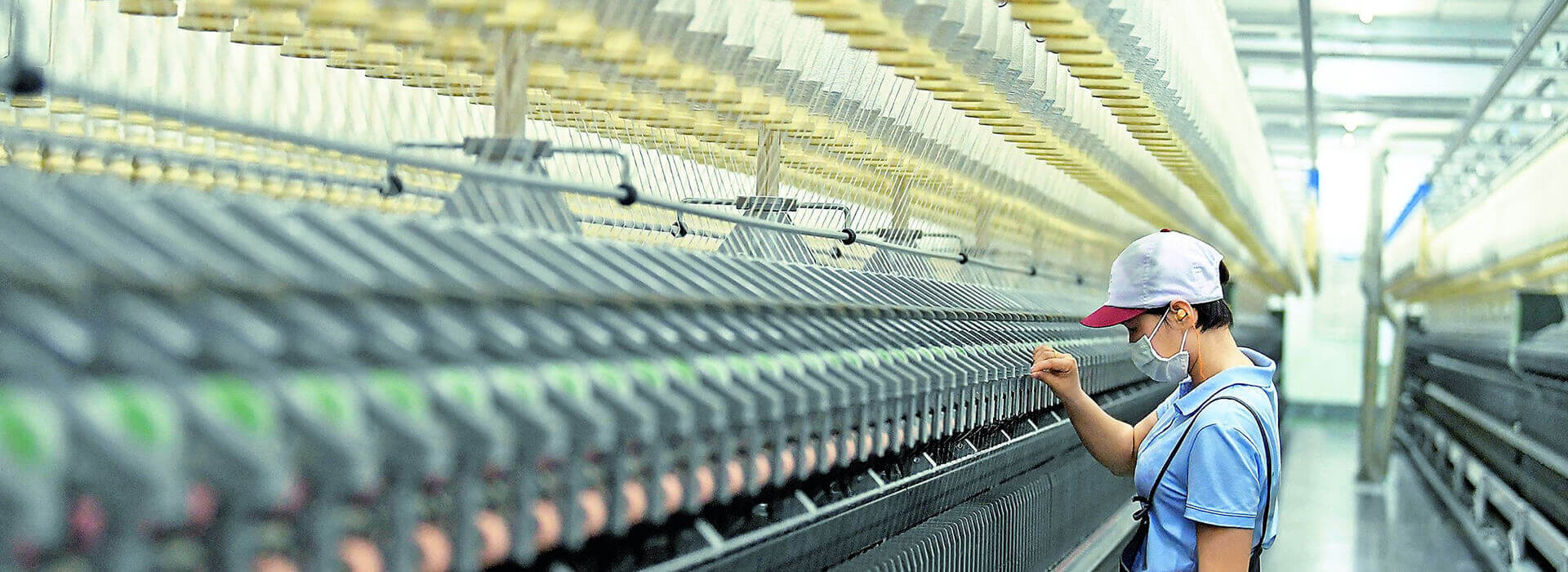

Background of the project

At present, bar code scanners are used to scan the labels outside the box one by one for weaving and wefting and winding in and out of the warehouse. The average daily scanning time is more than 28 hours and the workload is large, which wastes a lot of manpower and is not efficient.

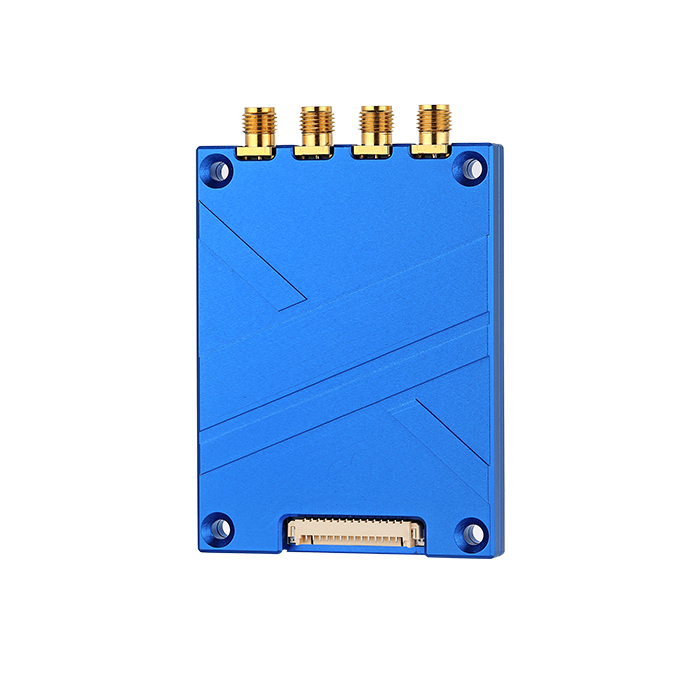

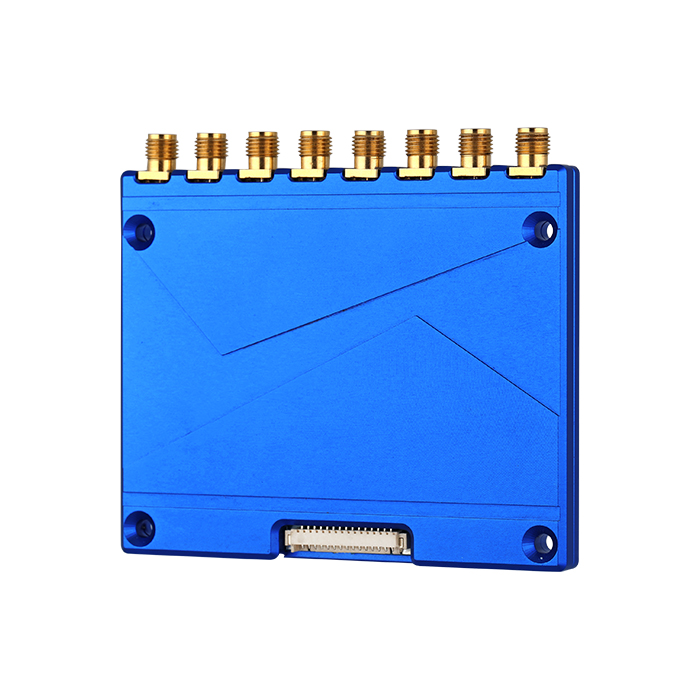

The modern warehouse management system based on RFID technology can automatically complete the scanning of multiple labels at one time, save time and manpower, effectively achieve the accuracy of inventory, detect idle weft yarns in time, and improve the efficiency of management weft allocation. Cooperate with automatic assembly line, AGV, manipulator and other equipment, use RFID technology to intelligently perceive equipment and materials, realize production automation, real-time and visualize warehouse management, and use special mobile terminals to achieve fast and accurate inventory. The successful implementation of the project will provide strong support for the information process of the subsequent automated allocation warehous

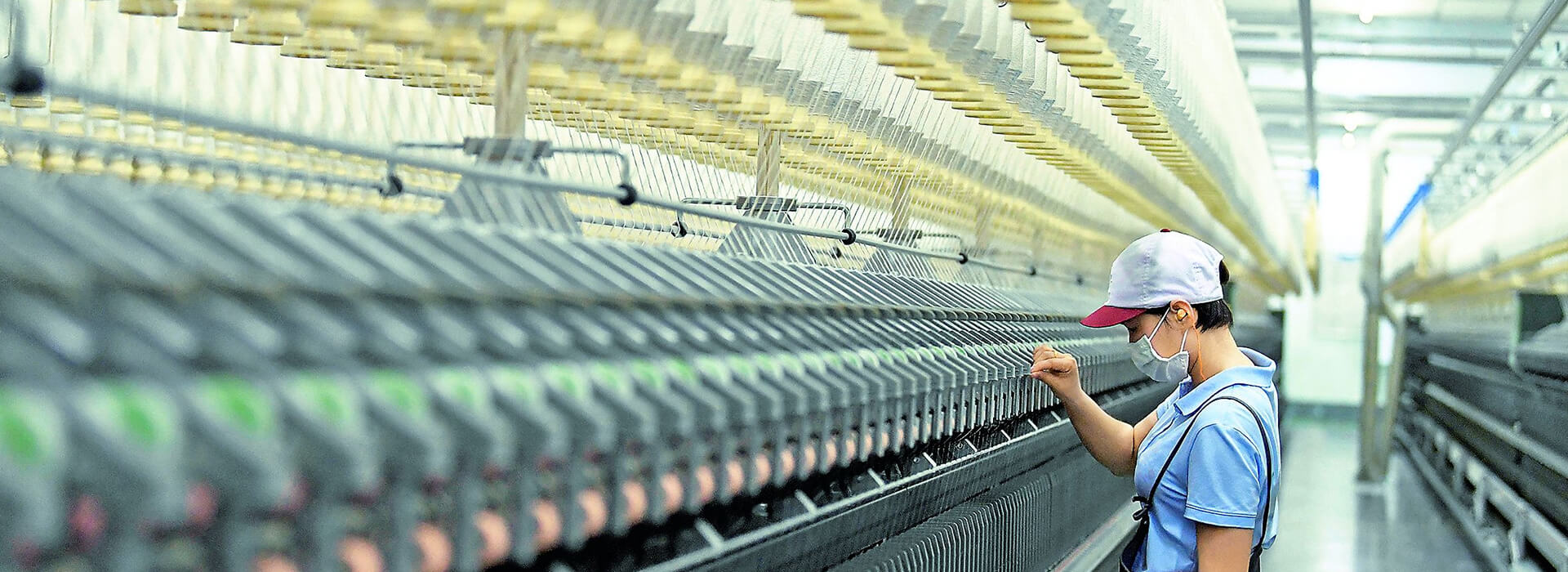

Goals

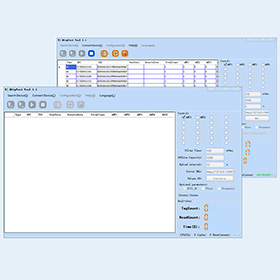

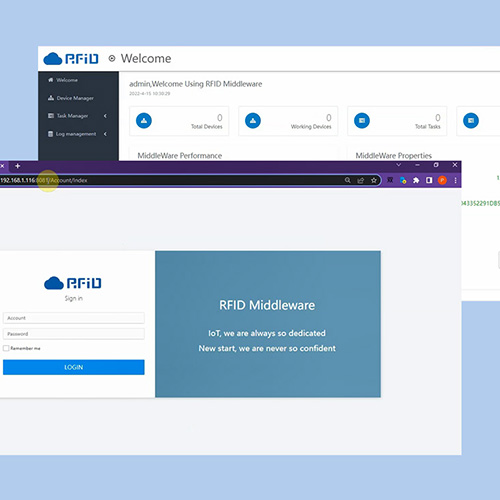

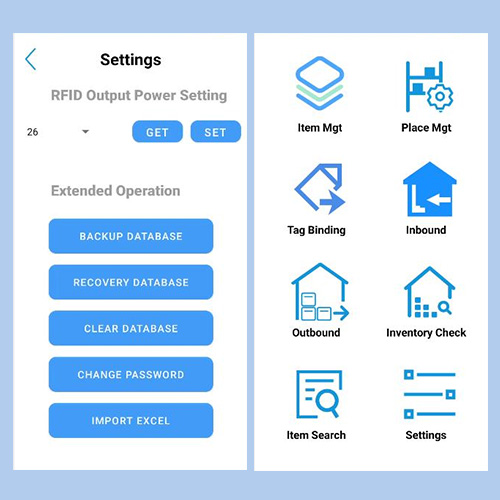

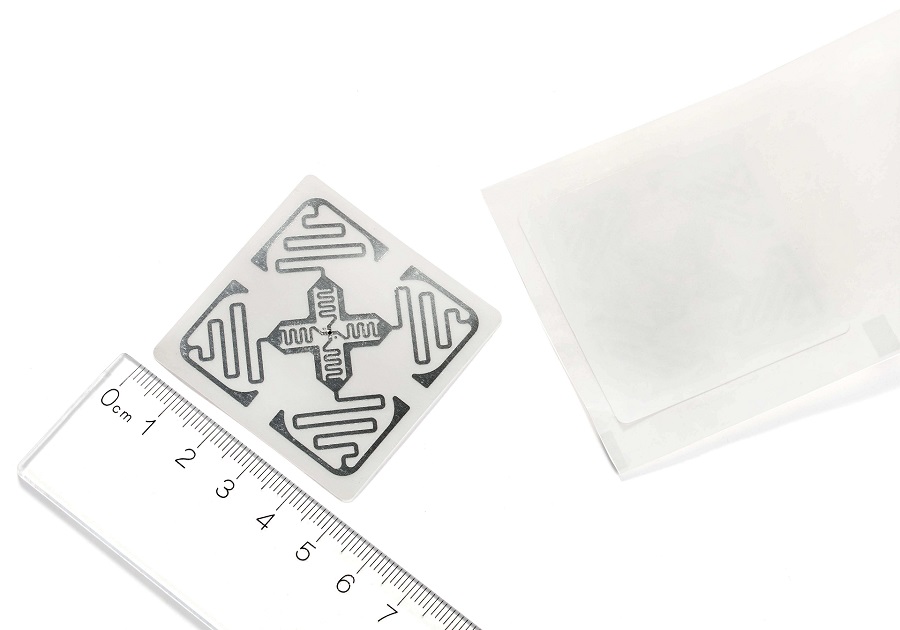

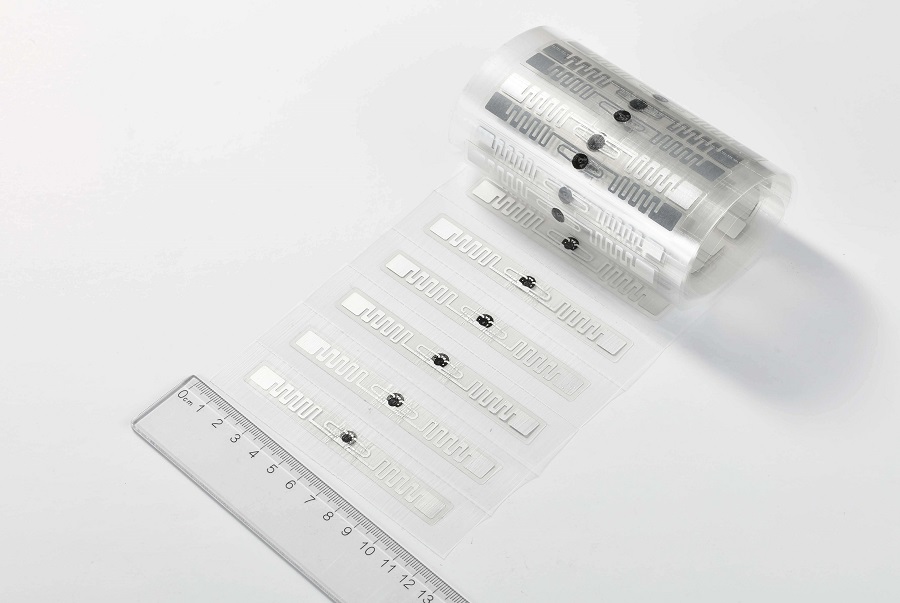

Starting from the weighing in the winding workshop, the robotic arm is used to pack and bind the pallet labels on the assembly line, and the incoming and outgoing documents are combined through the centralized identification channel to automatically complete the material flow from the winding workshop to the weaving warehouse and weaving workshop. At the same time, combined with handheld devices, Manage pallets and storage locations.

solution

The modern warehouse management system based on RFID technology can automatically complete the scanning of multiple labels at one time, save time and manpower, effectively achieve the accuracy of inventory, detect idle weft yarns in time, and improve the efficiency of management weft allocation. Cooperate with automatic assembly line, AGV, manipulator and other equipment, use RFID technology to intelligently perceive equipment and materials, realize production automation, real-time and visualize warehouse management, and use special mobile terminals to achieve fast and accurate inventory. The successful implementation of the project will provide strong support for the information process of the subsequent automated allocation warehouse.

Solution advantage

Realize the fully automatic management of the production workshop from weighing, coding, stacking, transportation and turnover, saving labor, and improving accuracy and efficiency.

Related application scenarios

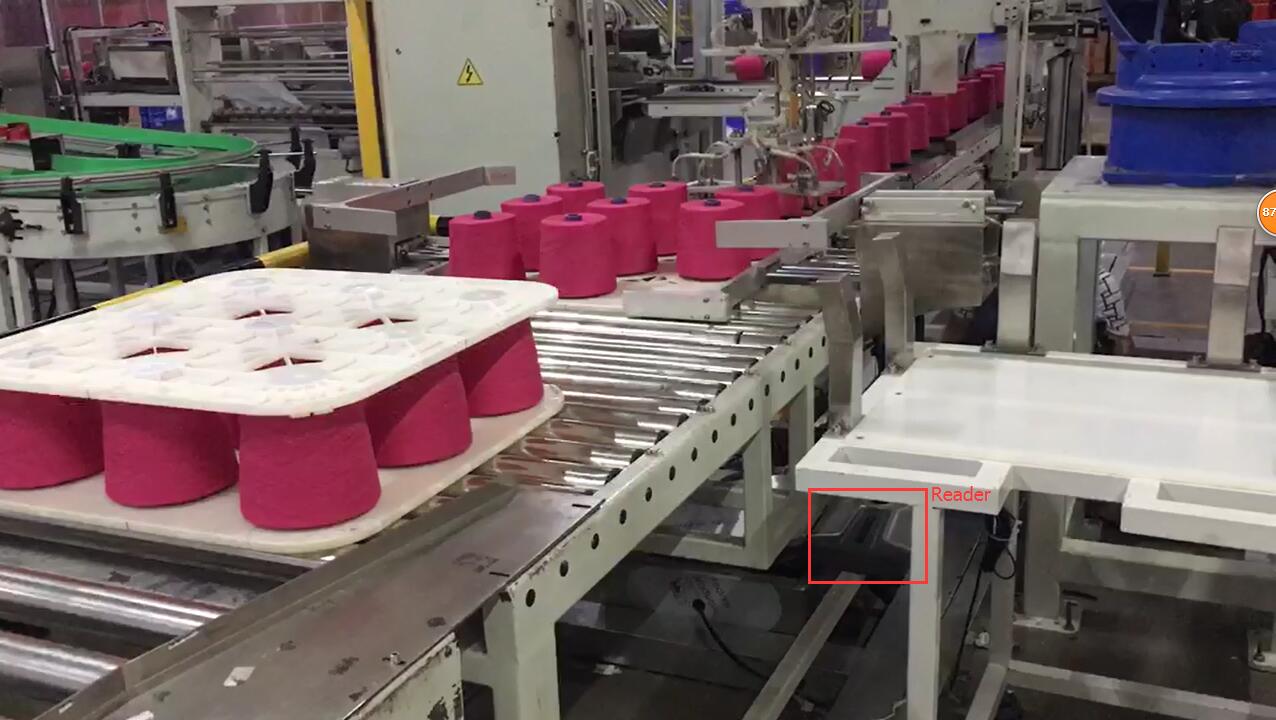

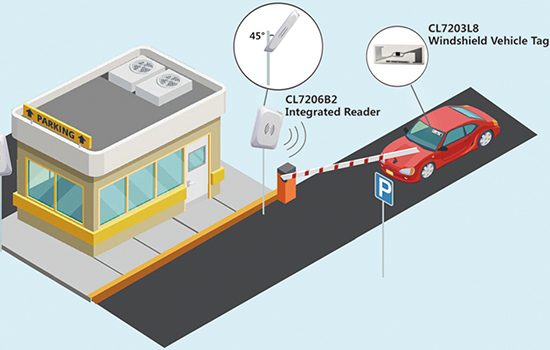

Robotic stacking

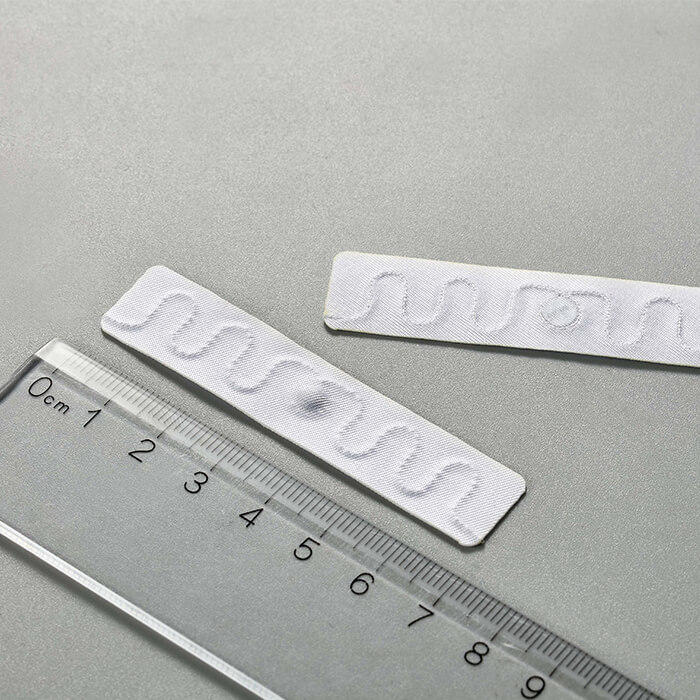

Automatic coding

AGV linkage

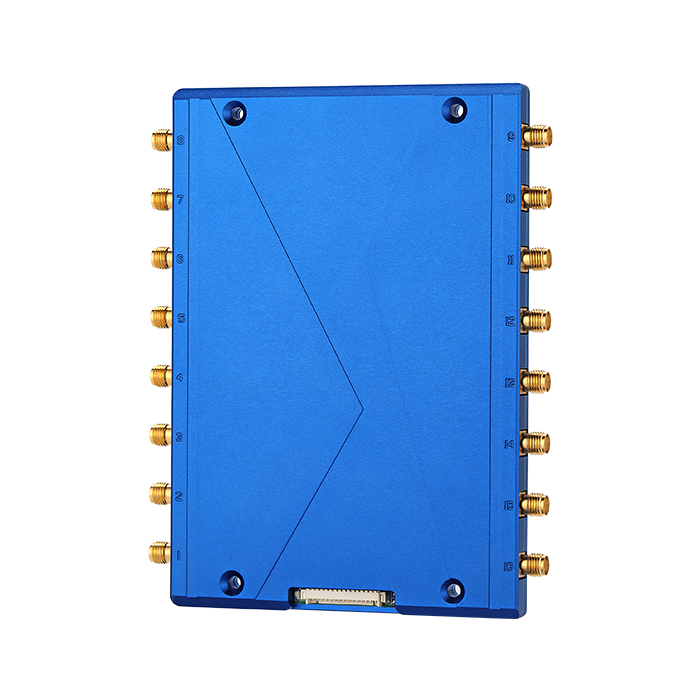

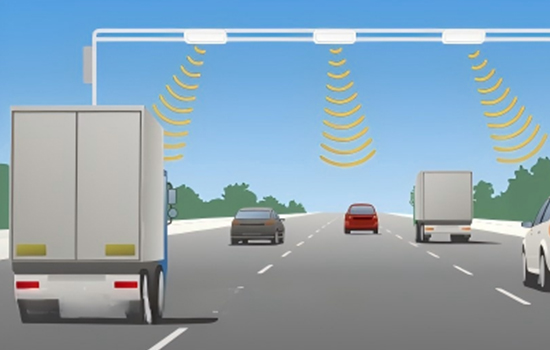

Inbound and outbound scanning