Background of the project

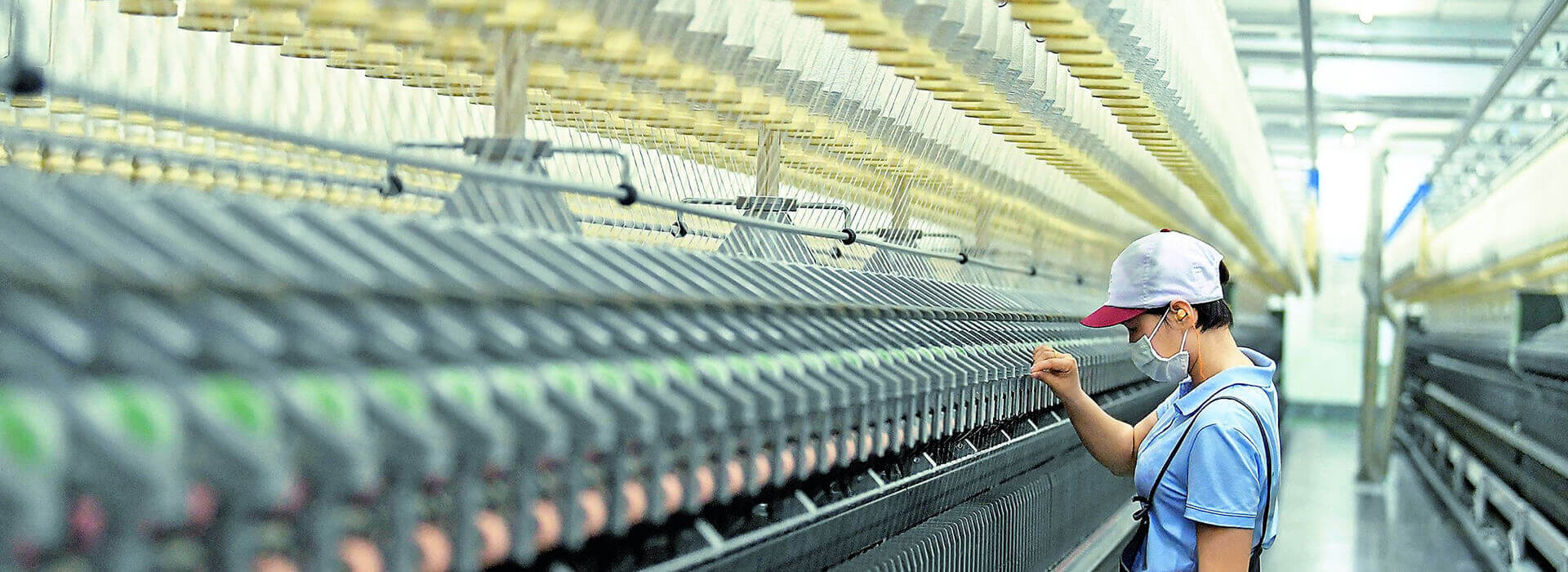

A factory is mainly engaged in the manufacture and sales of auto parts; auto parts technology development, technical consultation and other businesses. At present, the production line management mainly uses barcodes to manage parts, and there is a mature barcode management system. There are perfect management specifications and methods for pre-installation sorting and assembly inspection.

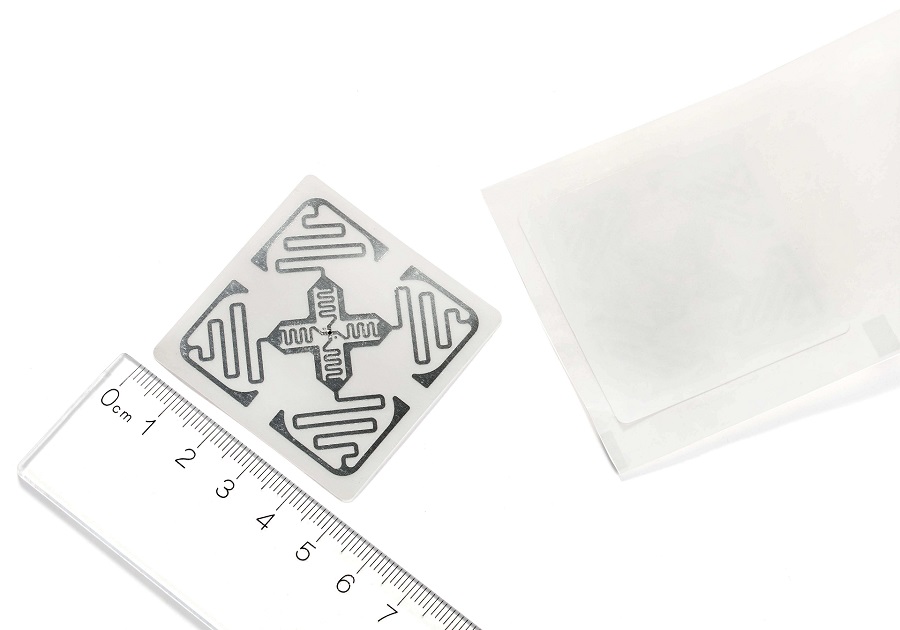

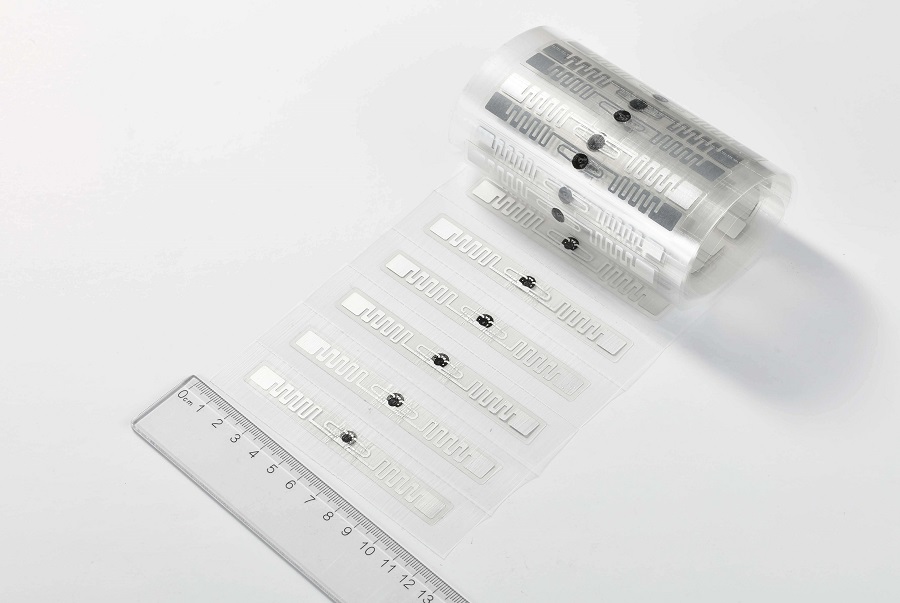

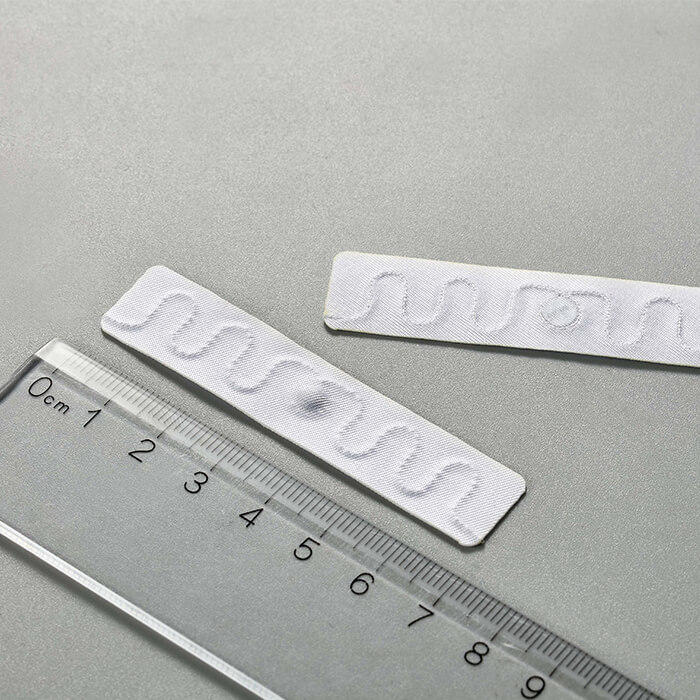

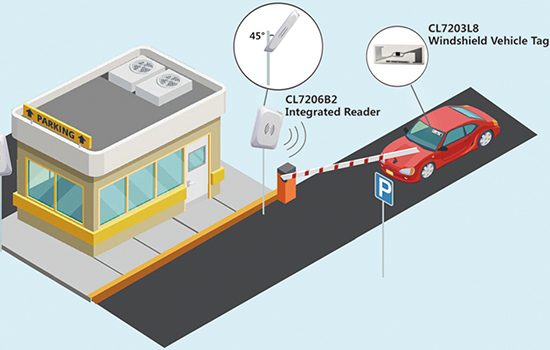

In order to speed up production, reduce inventory costs, improve yield rate, speed up logistics flow efficiency, and realize automatic production management monitoring, it is planned to replace the original barcode technology with RFID electronic tags

Using advanced management technology to transform the original bar code management system, it mainly solves the following problems:

1. The reliability of the data cannot be guaranteed. Since the information is collected manually, errors are inevitable, and the integrity and reliability of the data cannot be guaranteed;

2. The workload is large, the statistical work is lagging behind, and the data statistics, summarization and reports required for production management are completely manually completed. The processing is time-consuming, so there is no guarantee that the production information will be provided to the enterprise management personnel in time, resulting in a lag in the statistical work;

3. It cannot be combined with new technologies, cannot realize automatic production, and cannot realize automatic warehouse management;

RFID technology, a technology that can collect batch data in real time in harsh environments, can perfectly solve the above problems. The main advantages of using RFID technology are:

1. No contact is required, and the whole process does not require manual intervention, which can automatically collect data and is not easy to damage;

2. It can also collect information on objects in operation, and can identify multiple cards at the same time, which is more convenient to operate;

3. It can be applied to a series of requirements such as harsh production environment, unreachable personnel, large data storage, high real-time data transmission requirements, and reliable and effective data transmission.

Generally speaking, RFID, as an emerging technology, has great application prospects for real-time data collection in the working environment of production, warehousing and logistics, and can reduce manual operations for the existing production management process and warehousing of molding technology. , multi-dimensional automatic collection, realize the orderly supervision of the whole process, make each system operate efficiently, and improve production efficiency.