When combat supplies are tagged with RFID, ammunition depot custodians experience the awe-inspiring power of "scanning codes like counting troops" for the first time—the moment a handheld terminal swipes across the shelf, the information on the boxes of ammunition is synchronized to the command center. Behind this lies the profound reconstruction of military warehousing by RFID technology: by embedding anti-jamming military electronic tags into each item, a three-dimensional control network is built that enables "binding upon entry, tracking upon movement, and early warning upon anomalies." The traditional "human wave tactics" relying on paper ledgers are being replaced by digital sentinels. This upgrade of the support system, which began with a coding revolution, is redefining the "logistics speed" of modern warfare.

Breaking Through Pain Points

"In the past, it took 20 people 3 days to inventory a war reserve warehouse. Now, only one warehouse keeper needs to walk around with a handheld terminal and complete the entire inventory in 15 minutes—with a zero error rate." The director of a certain theater command's materials department described this transformation, which is precisely the military warehousing revolution brought about by RFID technology.

In modern warfare, the types of combat supplies such as ammunition, medical supplies, and individual soldier equipment are increasing exponentially. Traditional manual registration methods face three major challenges in managing these supplies:

Efficiency Black Hole

Manual inventory is prone to errors; in one exercise, a discrepancy in fuel records caused a two-hour delay in armored unit resupply.

Security Blind Spots

The movement of classified materials is difficult to track throughout the entire process, posing a risk of record tampering.

Slow Response

During earthquake relief efforts, it took six hours to locate critical rescue equipment in one warehouse.

In the crucial step of implementing the solution, each item is given a "digital ID card."

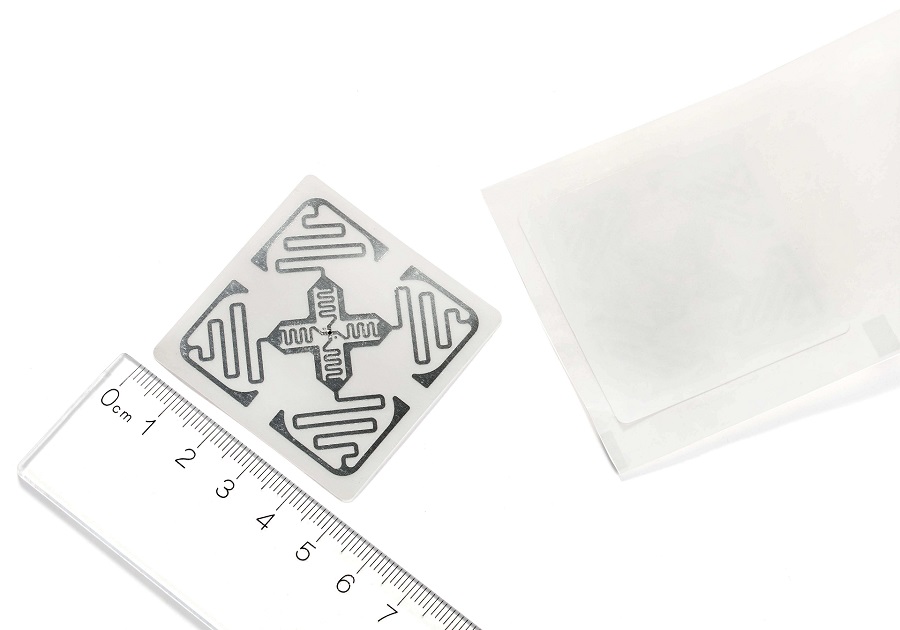

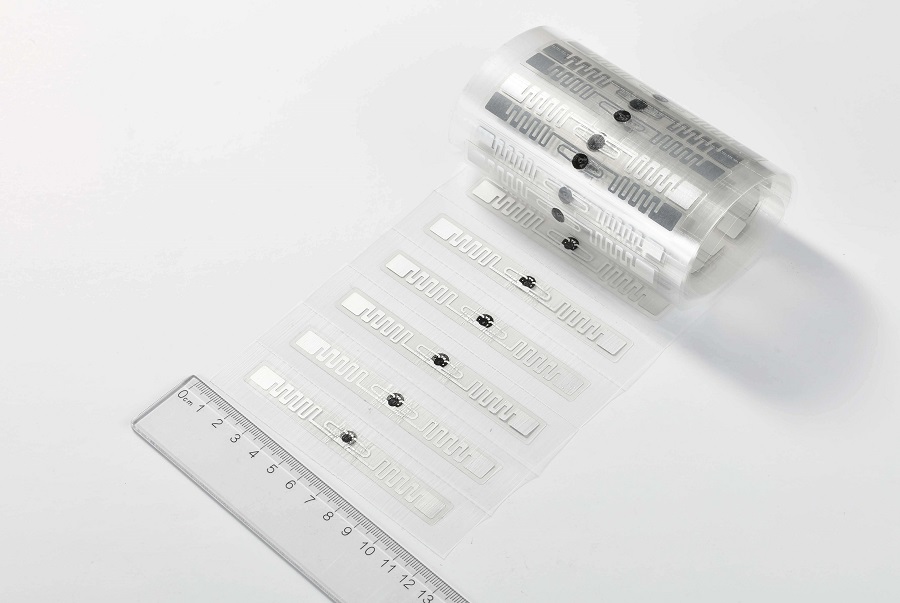

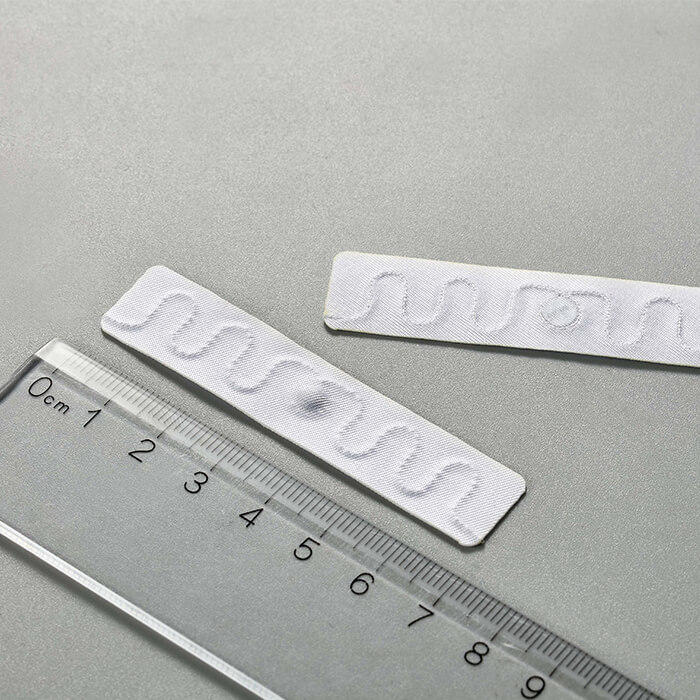

Customized Specialized RFID Tags: Metal-resistant and high/low temperature resistant tags are used in ammunition depots; flexible waterproof tags are adapted for individual soldier equipment. Each tag can store field information (production batch, maintenance records, etc.).

Hopeland Anti-Metal and Metal-resistant RFID Tag Sample Pic.

Second-level Response in Important Application Scenarios

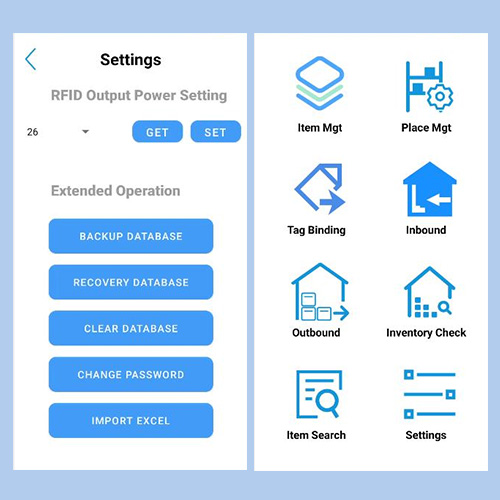

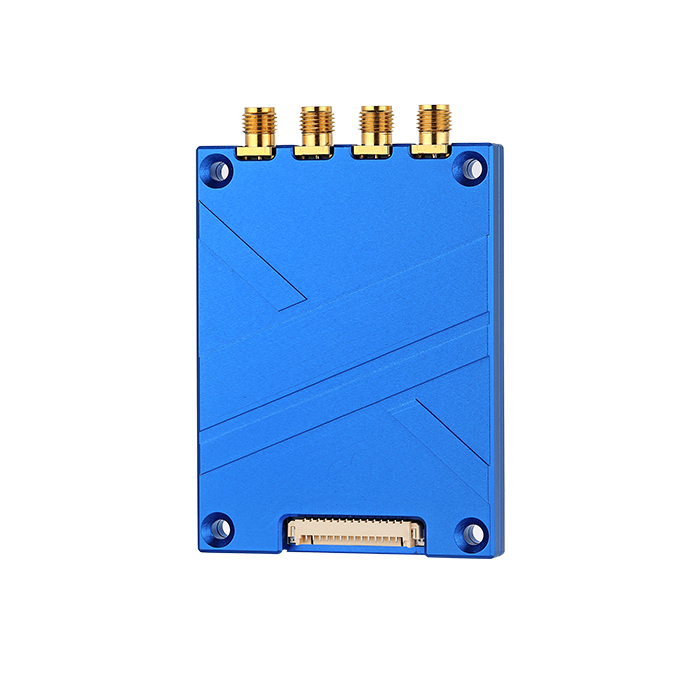

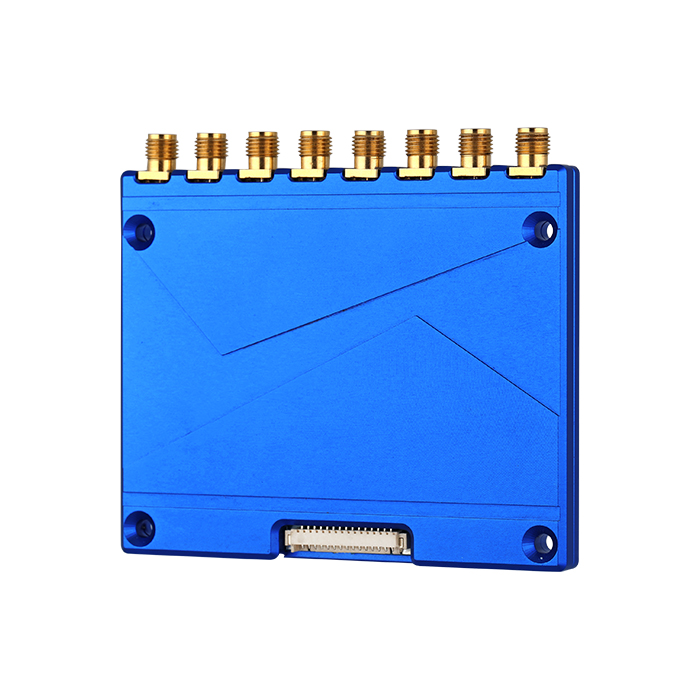

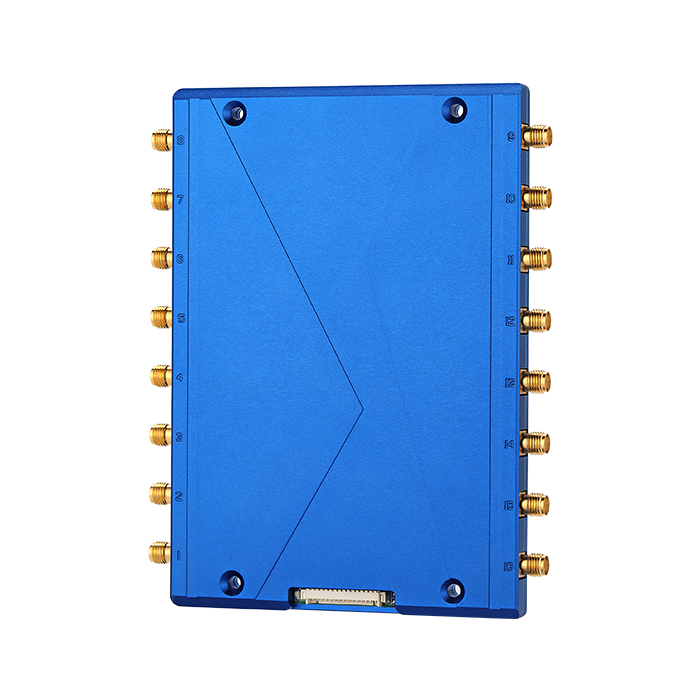

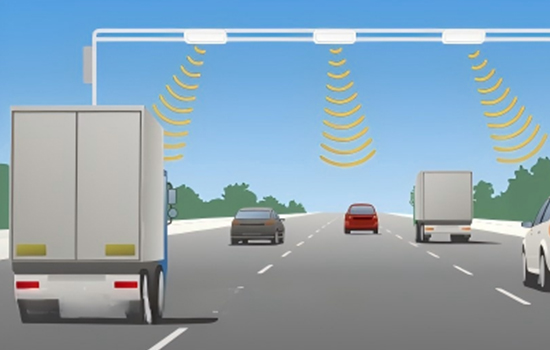

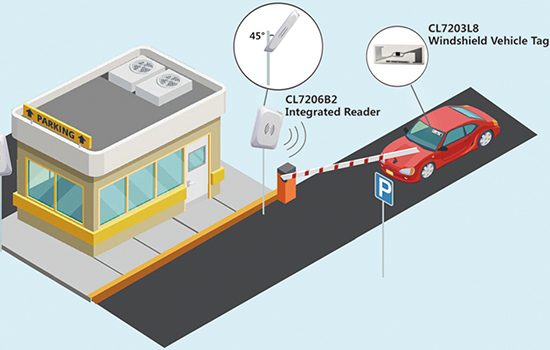

Smart Access Control Inventory: Multi-antenna readers are deployed at warehouse entrances and exits, instantly collecting data as materials pass by, 300% faster than traditional methods.

Mobile Real-Time Verification: Warehouse keepers use handheld terminals to scan shelves, simultaneously reading 500+ tags within 30 meters, enabling "inventory while moving" in fuel depots.

Emergency Material Location: Tags have built-in audible and visual alarm modules that can be activated via a dedicated frequency band in field conditions, locating critical materials within 30 seconds.

(Some texts come from the Internet, if there is any infringement, please contact to delete)