An RFID solution from Wattro automates tool and equipment tracking. The solution addresses common challenges faced by companies with numerous tools, including long search times, lack of inventory visibility, and difficulties in managing tool maintenance schedules.

"With our RFID solution, we can automate tool management and create added value that is unattainable with manual solutions. This ensures transparency and saves significant time and money, allowing our customers to complete their projects more efficiently and reliably."

Anton Trojosky – Co-founder and CEO, Wattro

Tool Tracking

Challenges in Managing Tools and Equipment

Companies with a large number of tools and equipment, especially those whose employees take tools to projects off-site, often struggle with chaotic management systems, leading to lost or misplaced assets, disrupted workflows, and increased costs due to the need for replacements.

Conventional tracking methods required the manual scanning of QR codes for each tool, a process often overlooked by employees focused on completing their tasks rather than on administrative tasks. This led to a chaotic management system where tools were lost, there was no accounting for damaged items, and a general lack of organization. The main problem was the impracticality of existing solutions, which relied heavily on manual input that was often neglected, leading to inefficiency and increased operating costs.

Image source: Think WIoT

Automated tool management with RFID

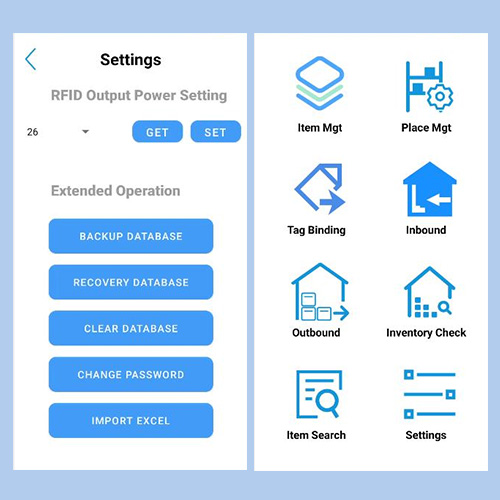

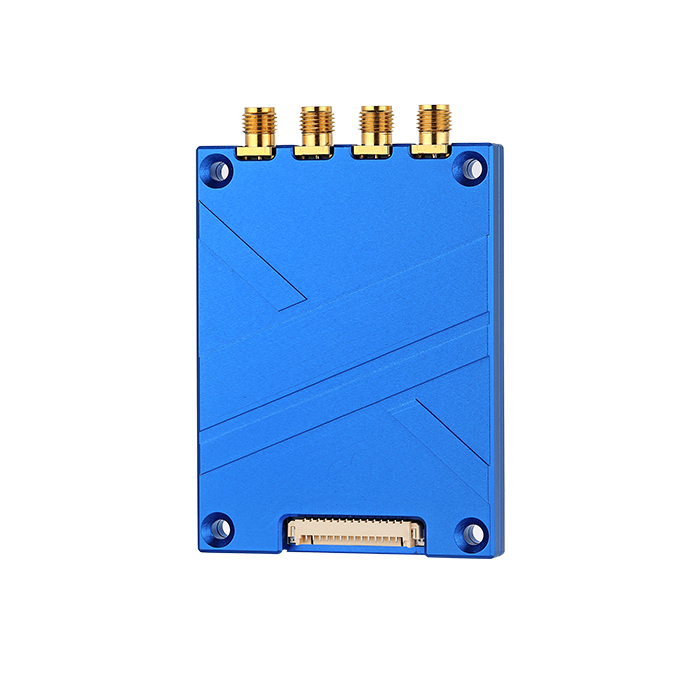

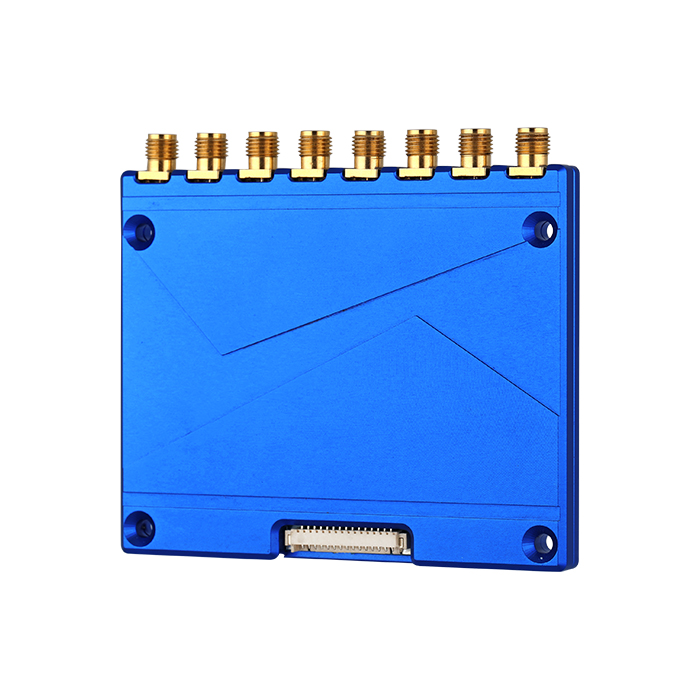

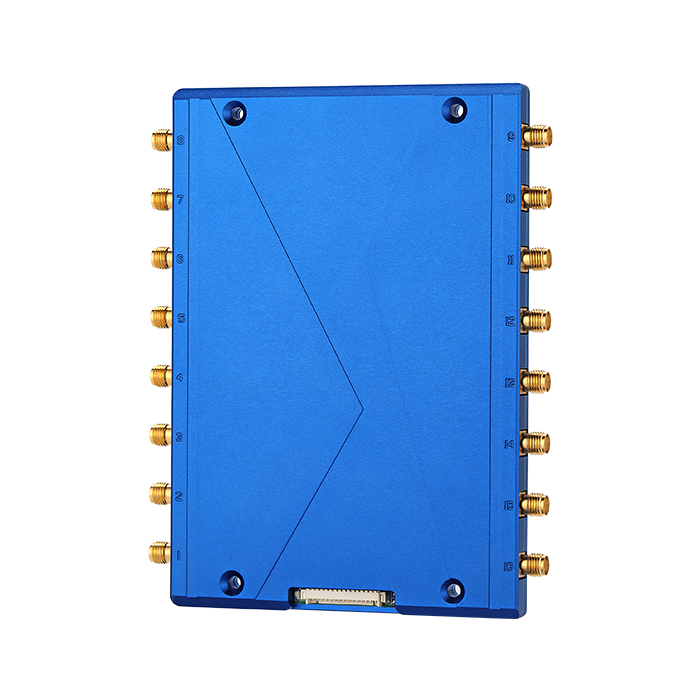

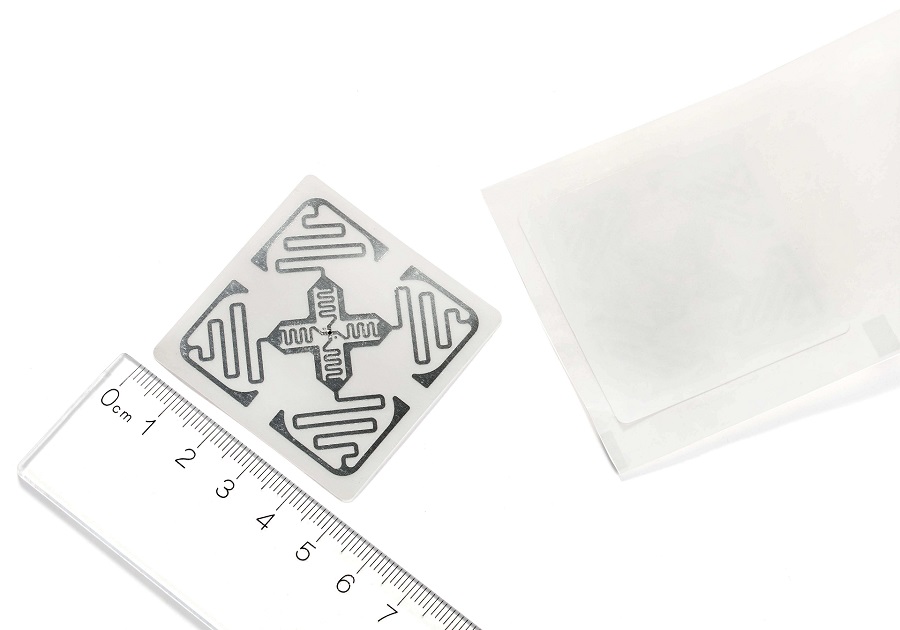

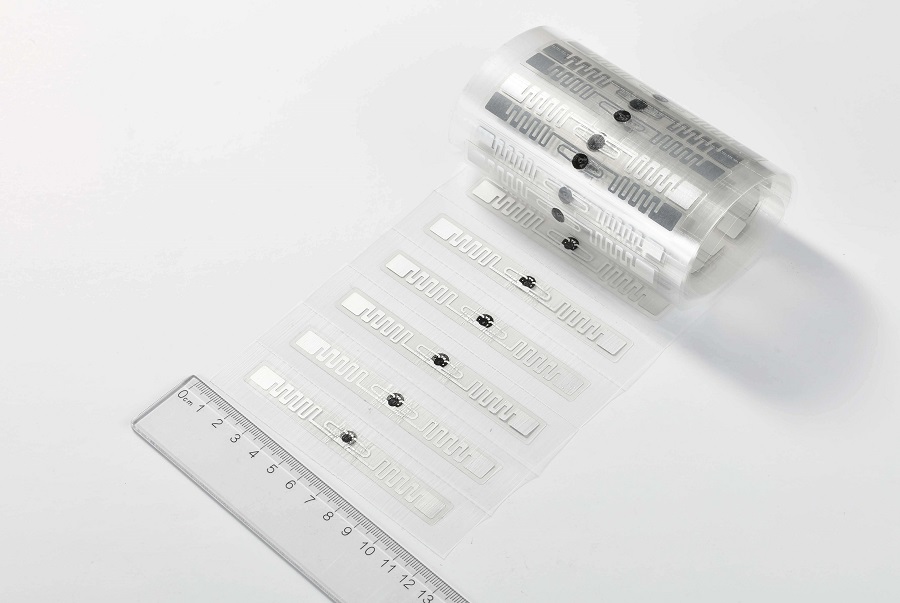

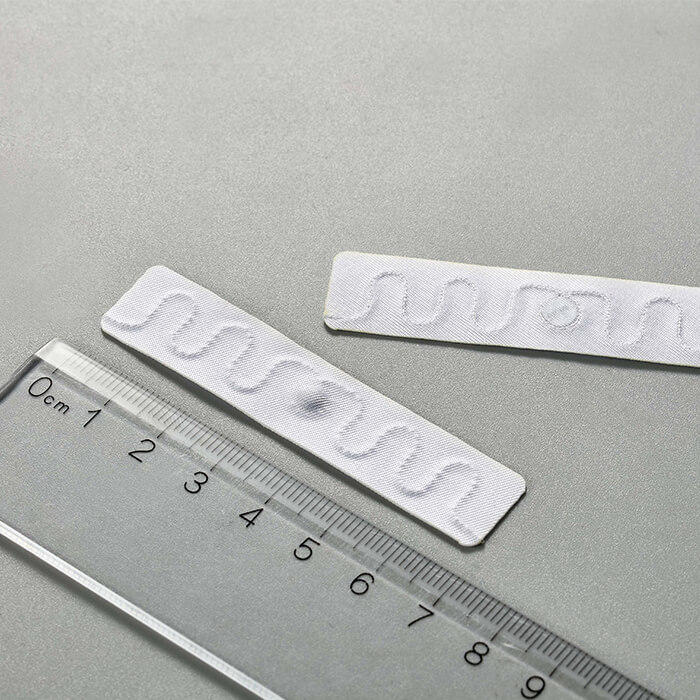

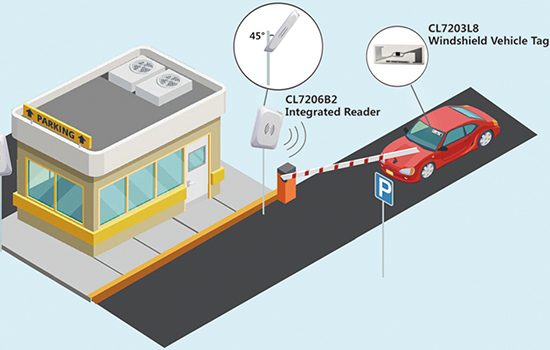

The RFID asset management solution offers complete visibility across the entire inventory and is accessible anytime, anywhere. The cornerstone of this innovation is the RFID scanning terminal developed by Wattro. Powered by the four-port UHF RFID reader module, it automatically detects and records tools as they are removed from or returned to the warehouse. If checkout is forgotten, a loud warning tone sounds. Tools are detected via radio frequencies as they leave the warehouse, enabled by RFID tagging the inventory. This integration simplifies the check-in and check-out process to a simple tap, eliminating manual scanning and reliance on smartphones. Asset management is thus streamlined.

Advantages of the RFID solution

The RFID solution offers many advantages for tradespeople. The time spent searching for tools can be drastically reduced from an average of 5-10 minutes per employee per day to about two minutes. The solution also prevents tool loss and the associated costs. Companies can save annual costs on unnecessary tool or equipment replacement. By automating the tracking process and ensuring efficient tool and equipment management, operational efficiency is improved. Comprehensive inventory visibility, combined with real-time updates and streamlined equipment requests, minimizes delays and streamlines the management of inspections and certifications.

(Some pictures and texts come from the Internet, if there is any infringement, please contact to delete.)