In the fierce competition in the automobile manufacturing industry, how to improve production efficiency, reduce costs and optimize inventory management has become the focus of major automobile companies. SAIC, as one of the leading companies in China's automobile industry, has recently taken an important step in the field of logistics management: introducing an innovative solution that combines drones with RFID (Radio Frequency Identification) technology for inventory counting, achieving a significant reduction in labor costs and setting a new benchmark for the industry.

As a subsidiary of SAIC Group, SAIC Anji Logistics manages millions of cars transported by SAIC in China every year. Their garages must keep data on the status, quantity, and address of thousands of cars and conduct regular inventory checks. However, the traditional inventory counting method relies on a large amount of manual operation, which is not only time-consuming and labor-intensive, but also prone to errors. It is difficult to adapt to the needs of the rapid development of the modern automobile manufacturing industry and seriously affects logistics efficiency. In order to solve this pain point, SAIC Group actively explored and introduced a company's "drone + RFID" inventory counting solution. This solution realizes the automation and intelligence of inventory counting by integrating the high-altitude operation capabilities of drones and the precise identification capabilities of RFID technology.

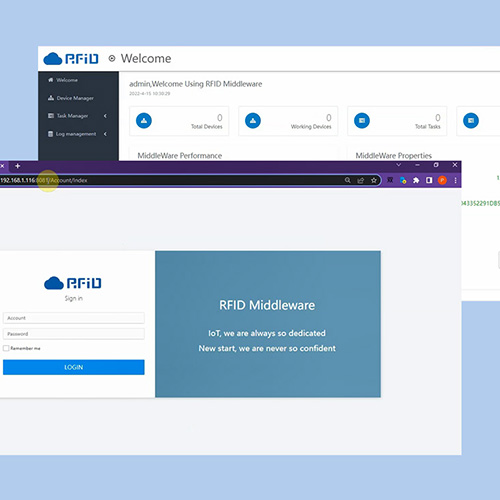

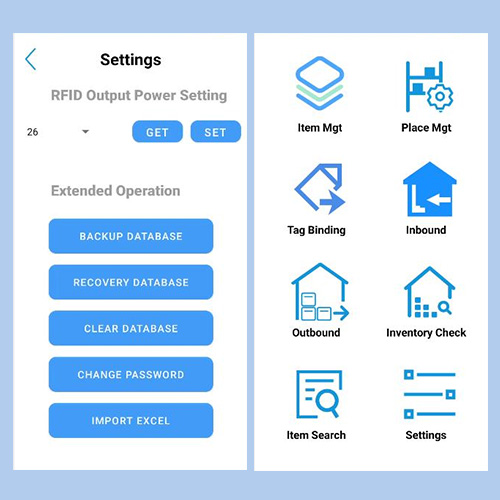

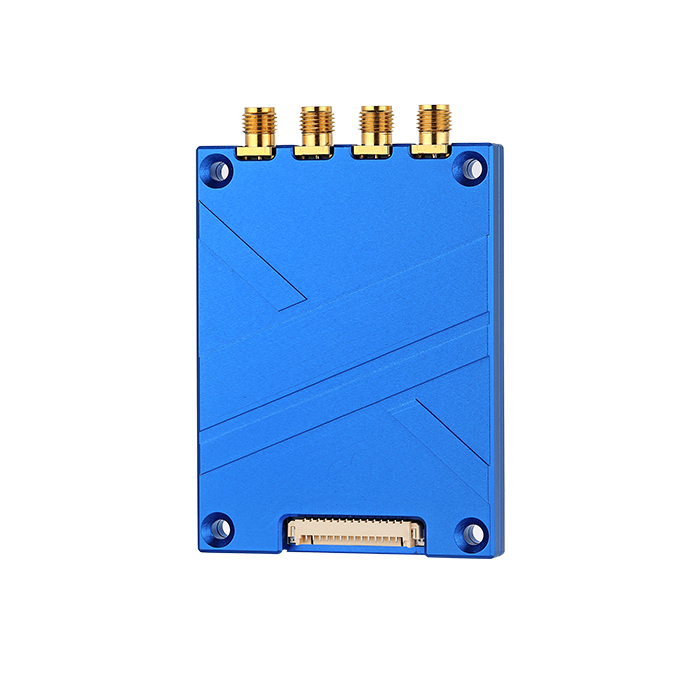

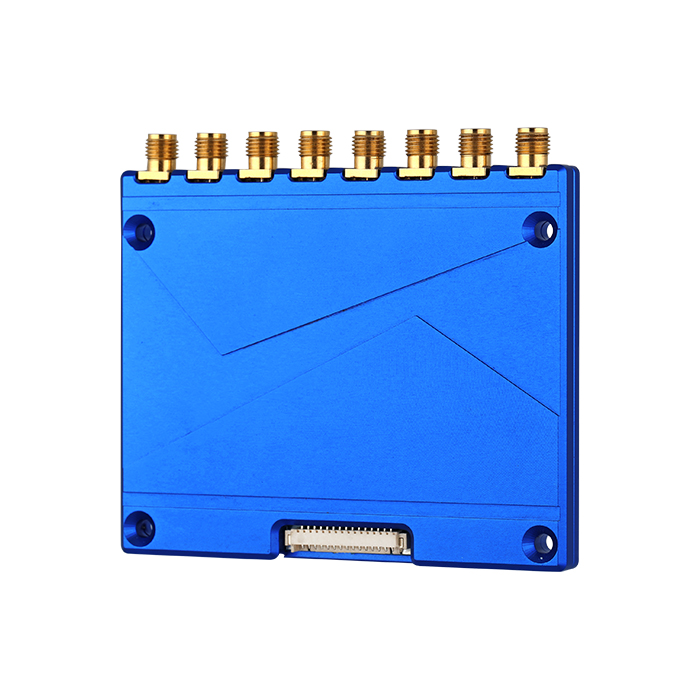

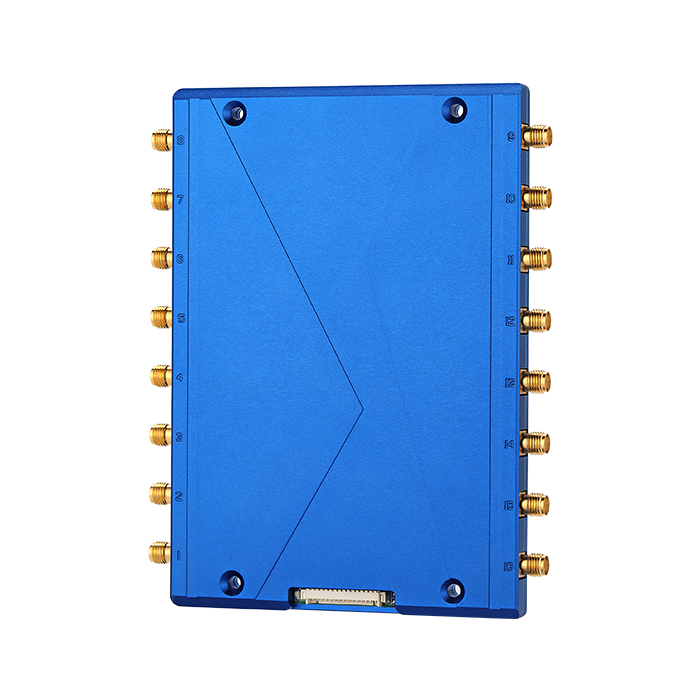

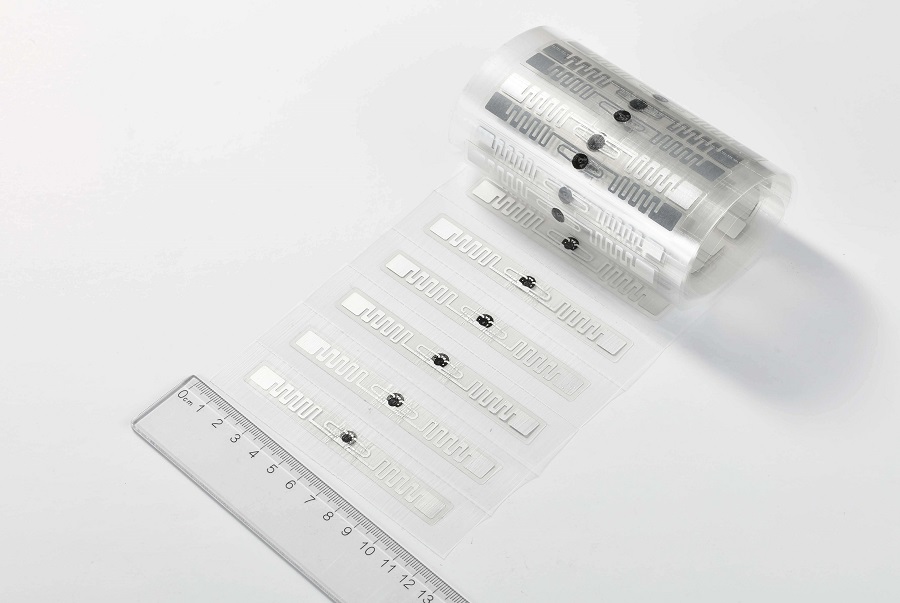

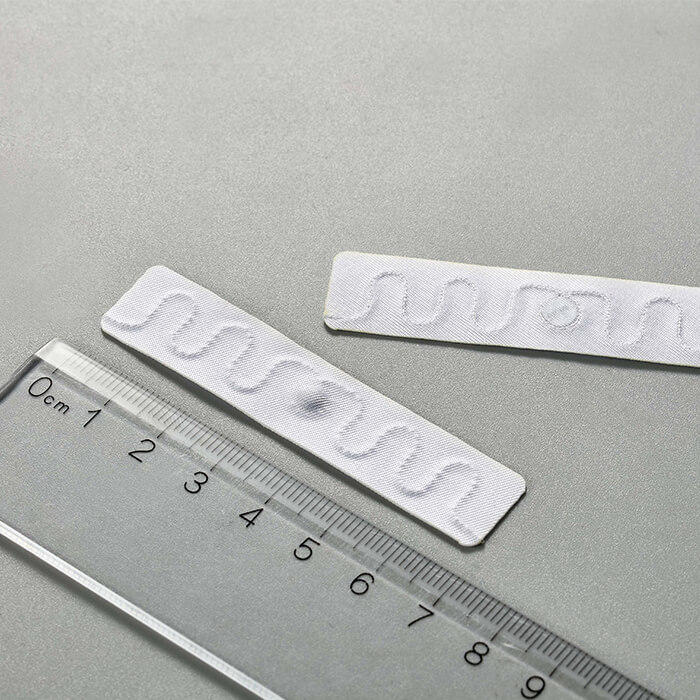

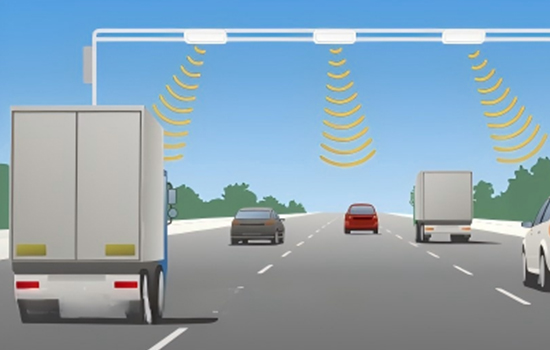

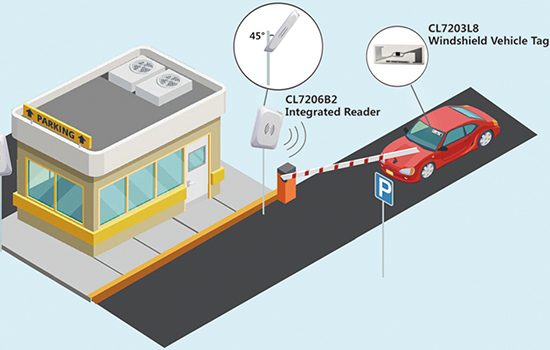

Drones play an important role in inventory counting. They are equipped with high-precision RFID readers and fly autonomously according to preset flight routes, covering every corner of the warehouse, thus perfectly achieving "efficient coverage and accurate identification". RFID technology provides accurate data support for inventory counting. Every car is affixed with an RFID tag, which stores the vehicle's unique identification information and related data. When a drone flies over a vehicle, the RFID reader quickly reads the information in the tag and transmits the data to the backend system for processing. This process enables real-time data updates and accurate records, ensuring the authenticity and reliability of inventory data.

(Some pictures and texts come from the Internet, if there is any infringement, please contact to delete)