Background:

One large Mongolia mining company is searching for a Near-Field Communication system to simplify the tracking of trucks from its coal mines to weigh stations, and through its processing plant. Hopeland's partner XXX company have cooperated with Hopeland for several years and have rich experience in RFID Vehicle Tracking, Smart Weight System etc. Therefore they explained the advantages of their RFID solution and get the contract from this mining company.

Solution:

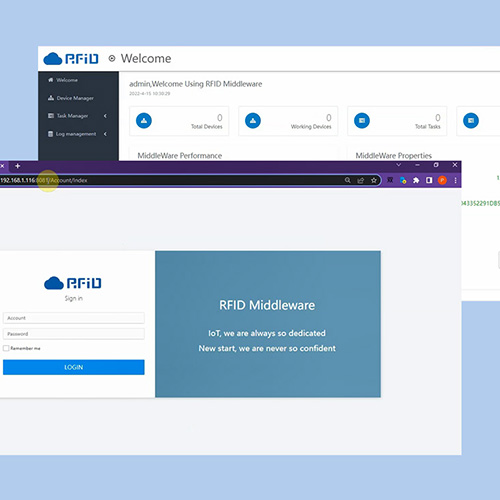

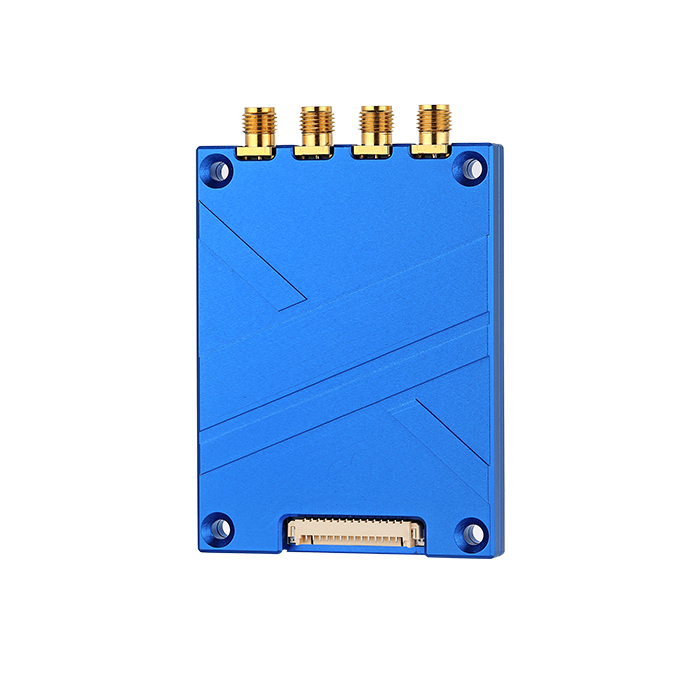

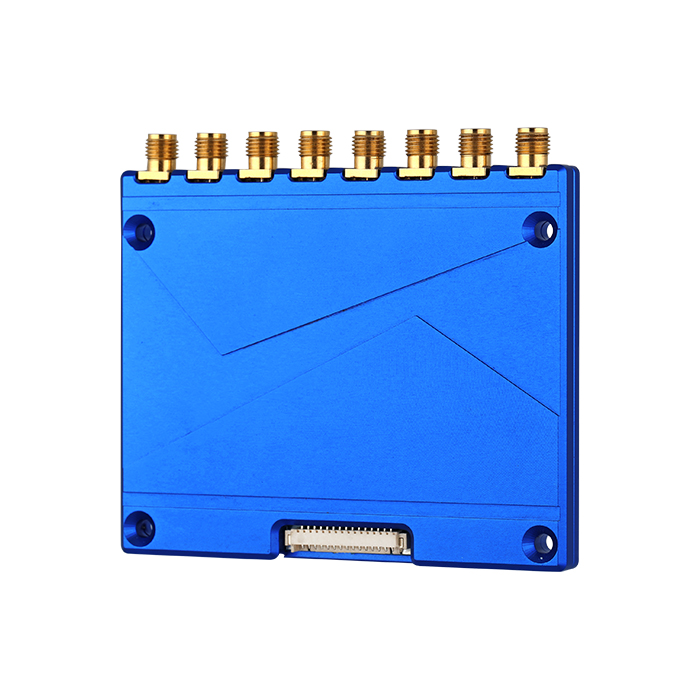

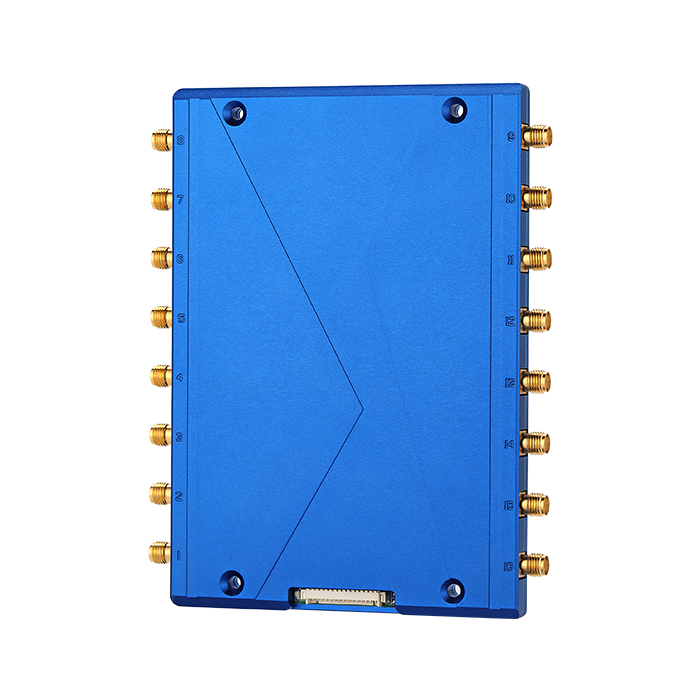

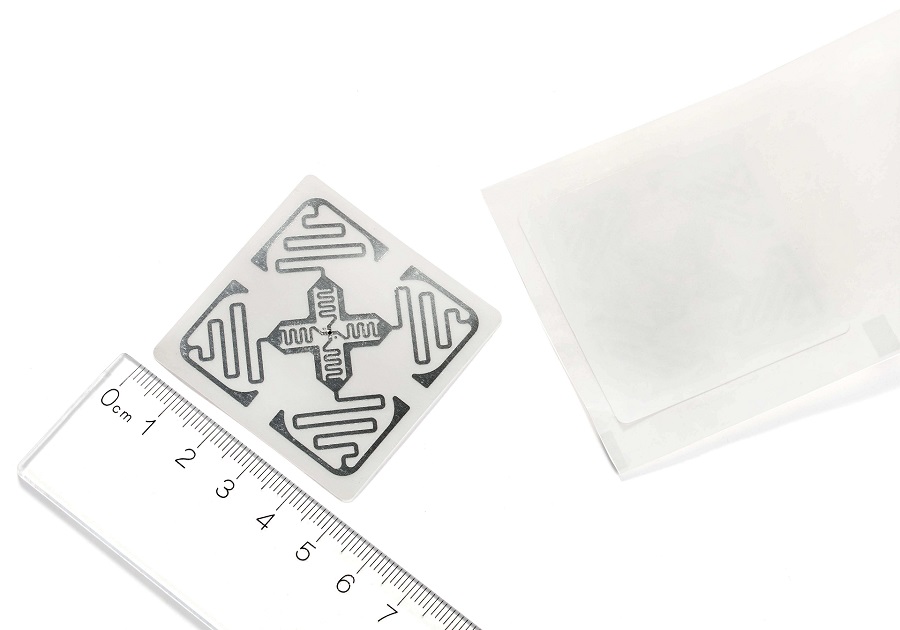

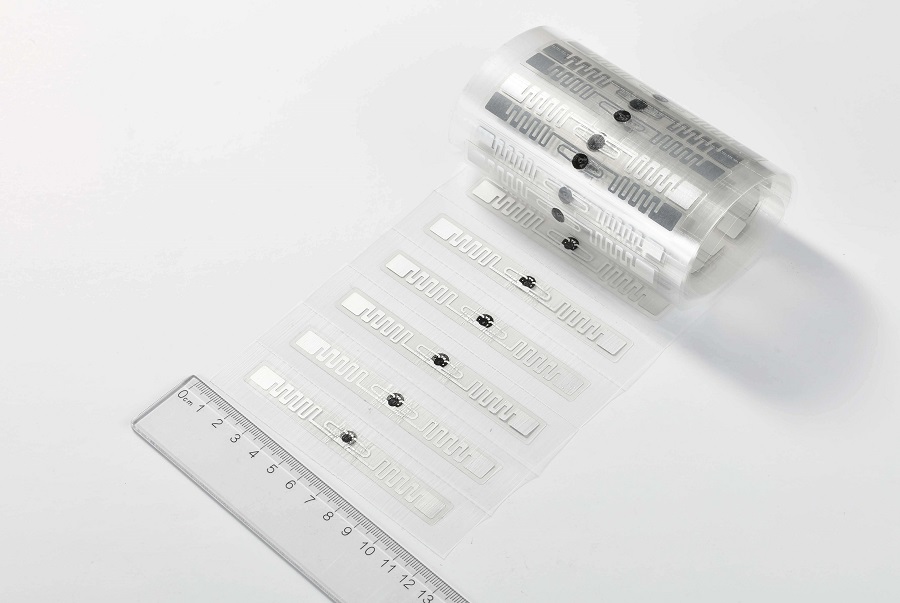

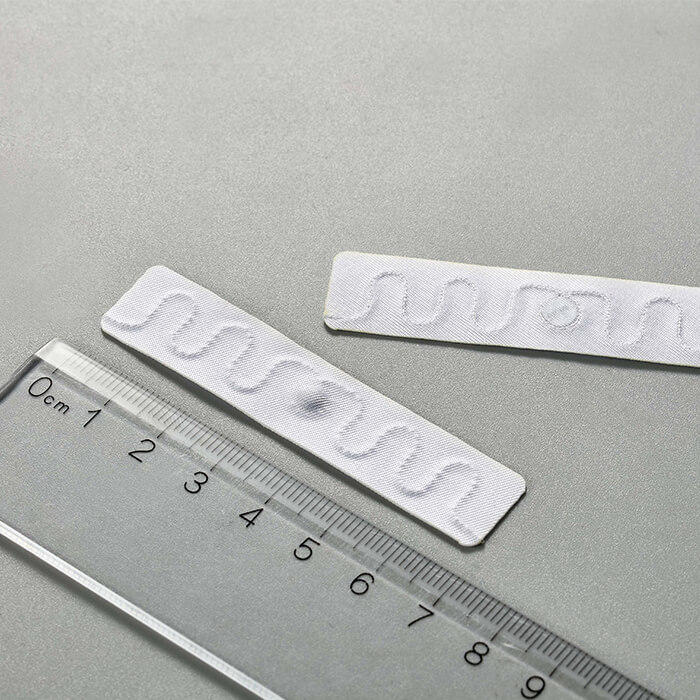

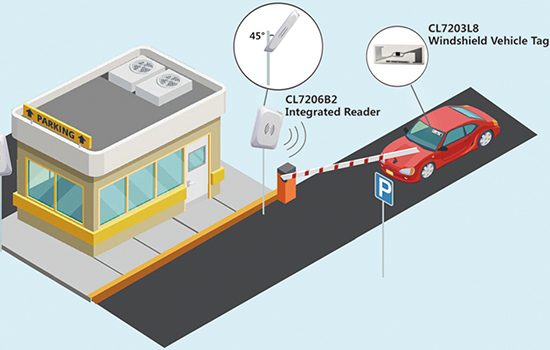

In this solution, Hopeland Integrated Reader CL7206B2 was installed at Forklifts, Weighting Station , Entry Gates, Exit Gates . RFID Windsheild Tag was installed at the Coal Vehicles as an Indentification .

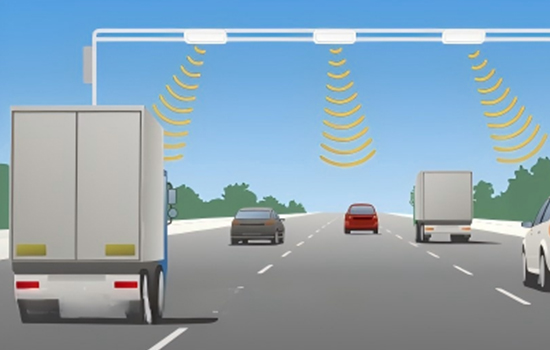

In this case, the movements of Coal Vehicles would be monitoring by RFID Readers at each station , Software tracks the truck’s location, and you can usually run a variety of reports like the time it stayed at this site, the Coal Volume it loaded.

Highlights of Hopeland Reader:

-Work normally at extreme cold weather (-40℃ in the winter of Mongolia)

-Long distance reading from Reader to Vehicle Windsheild (>15m)

-Fast & Accurate reading rate (>98%)

-Easy installation and convenient configuration

Application Effectiveness of RFID tracking for trucks operating in mines

• Automate entry and exit of verified trucks at the mines

• Prevent entry of unauthorized trucks into the mines.

• Maintain an automated record of truck movement into and out of the mines.

• Individual truck details are registered in the Vehicle Management System

• Automatic weighing & matching vehicle informations by RFID tag.

• Extensibility for worker safty by RFID Readers at Forklift, Coal Vehicles