-

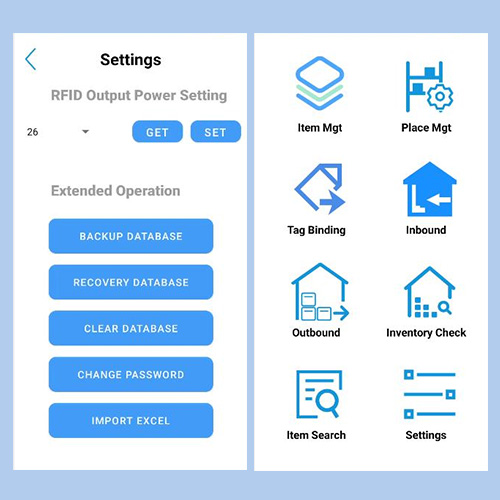

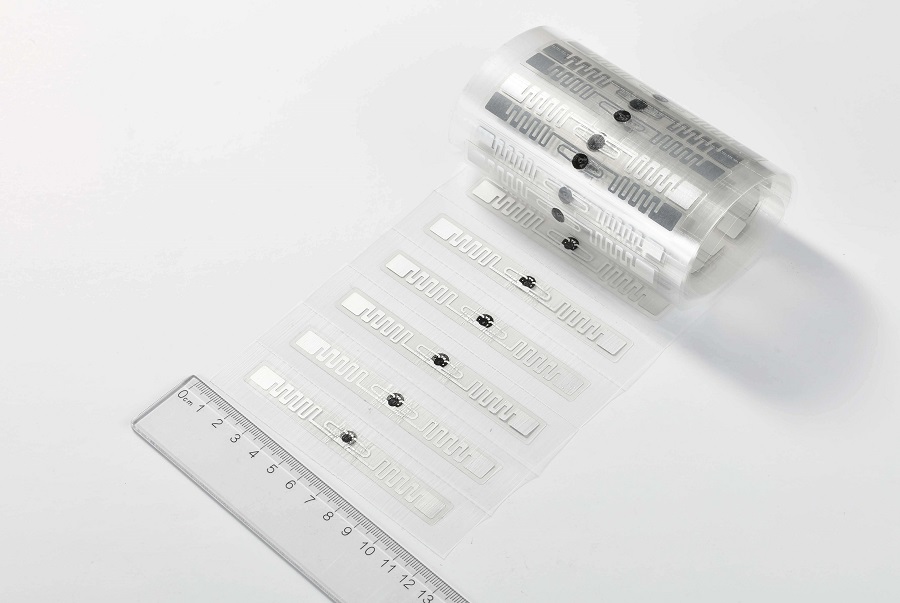

Long-distance Reading, Waterproof, Anti-corrosion, Easy to carry

Long-distance Reading, Waterproof, Anti-corrosion, Easy to carry -

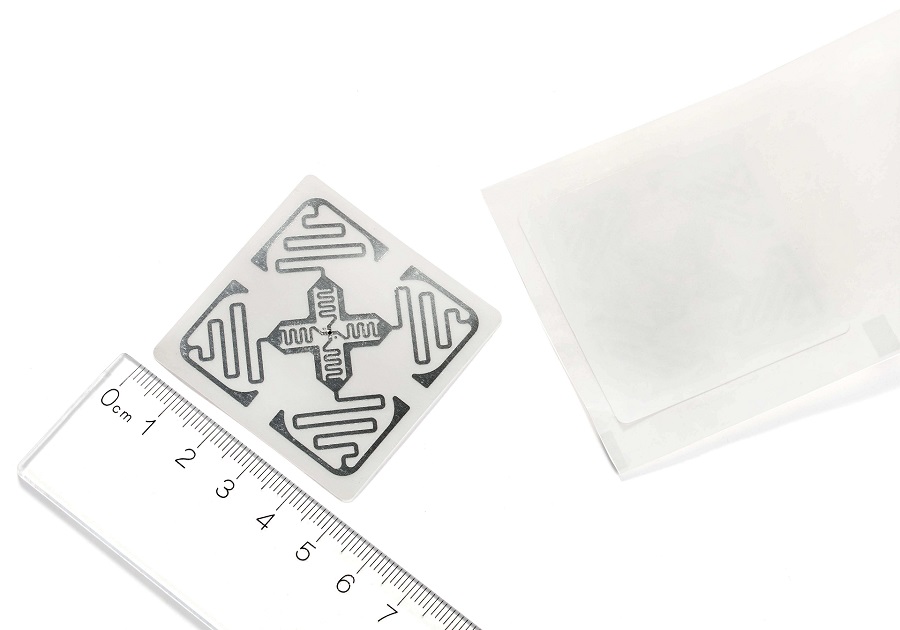

Multi-label Identification, High Label Identification Sensitivity, And Unique Identification Code

Multi-label Identification, High Label Identification Sensitivity, And Unique Identification Code -

Mainly Used In Warehouse Management, Asset Management, Material Management and So On

Mainly Used In Warehouse Management, Asset Management, Material Management and So On

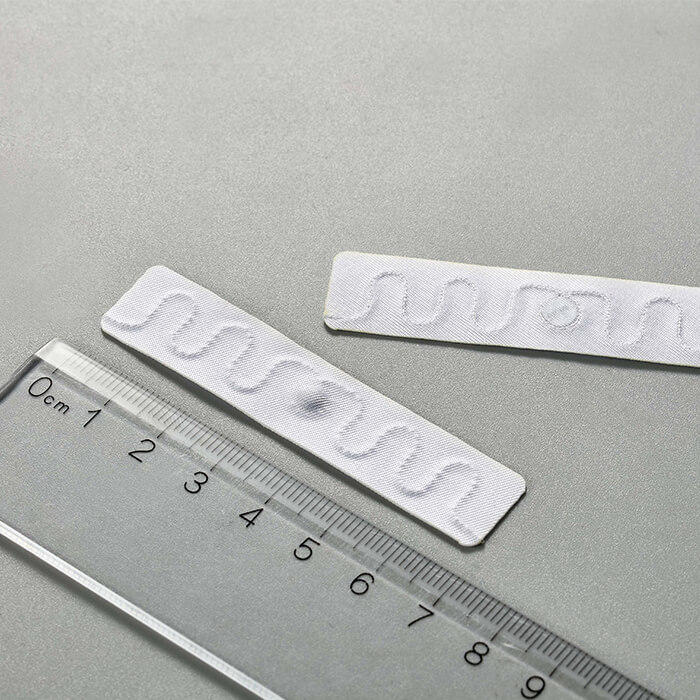

Easy to fix, not easy to fall off, can tightly fit irregular or cylindrical objects such as pipes and cables.

High-quality materials, supporting waterproof, temperature resistant, wear-resistant and other characteristics, suitable for complex environments such as industrial and outdoor environments.

The identification is intuitive and can print text, barcodes, and QR codes, making it easy to quickly identify and trace information.

Easy to install, no need for additional tools, can be fixed after wrapping, improving marking efficiency.

Easy to fix, not easy to fall off, can tightly fit irregular or cylindrical objects such as pipes and cables.

High-quality materials, supporting waterproof, temperature resistant, wear-resistant and other characteristics, suitable for complex environments such as industrial and outdoor environments.

The identification is intuitive and can print text, barcodes, and QR codes, making it easy to quickly identify and trace information.

Easy to install, no need for additional tools, can be fixed after wrapping, improving marking efficiency.

-

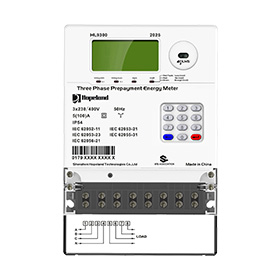

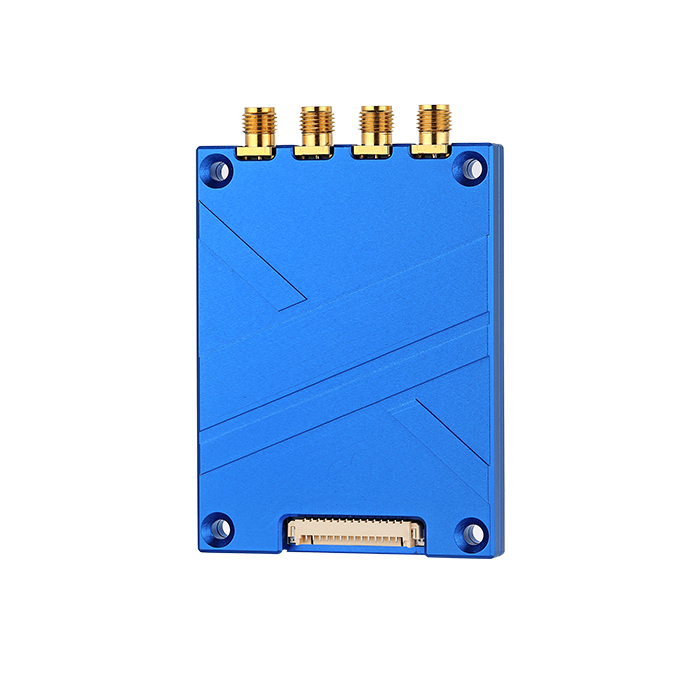

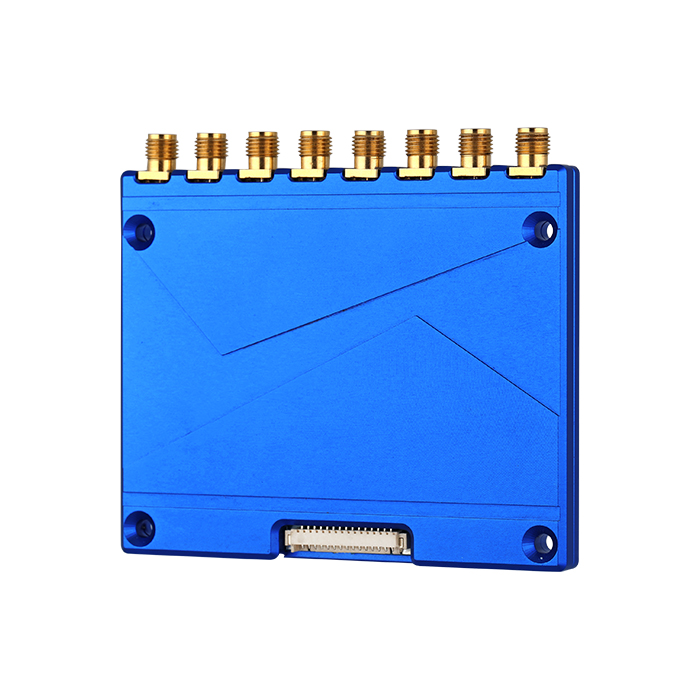

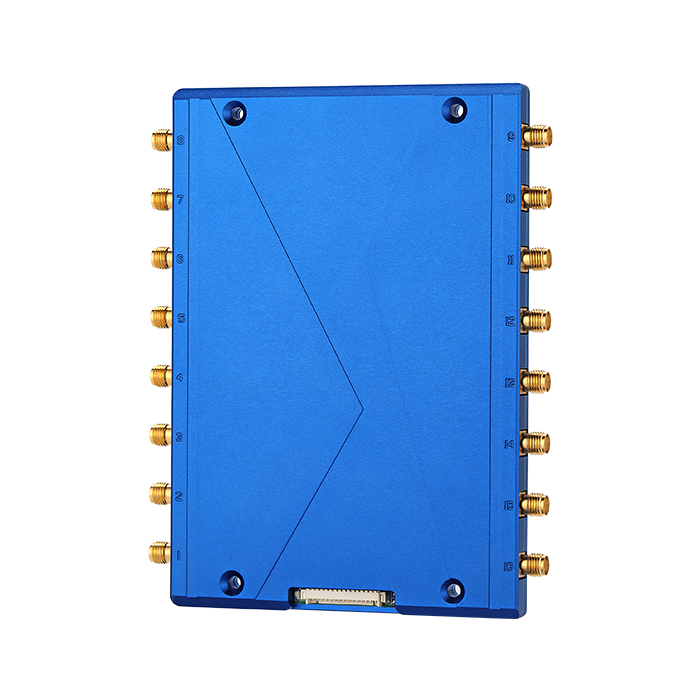

Physical Parameter

Housing Material: PP PP 400 x 25 x 3 mm Customize logo printing, coding, writing data, etc. Installing: hanging -

Performance Parameter

Protocol: ISO/IEC 18000-6C EPC Class 1 Gen 2 Frequency: 860MHZ~960MHZ Chip IMPINJ R6P EPC Area 128bit

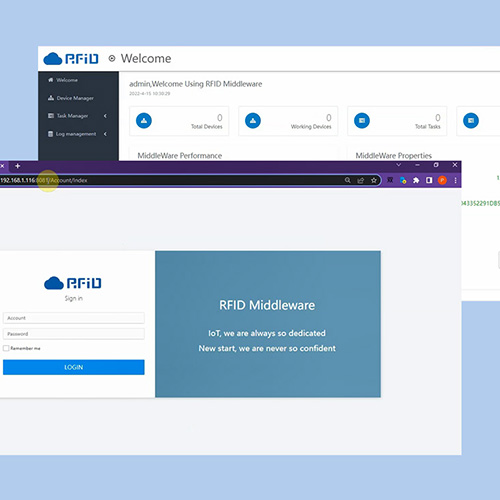

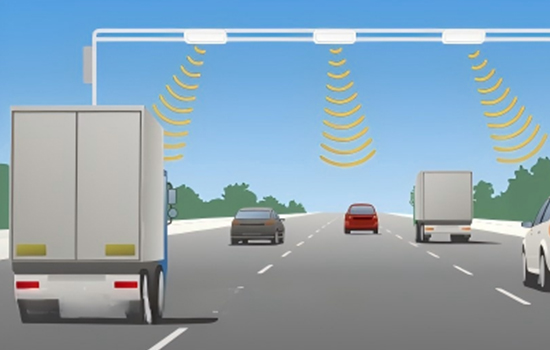

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

-

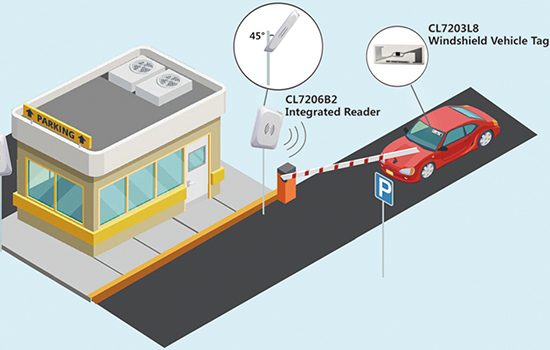

CL7203L8RFID Tag Sticker for Vehicle WindshieldRFID sticker/label fragile, especially designed for vehicle windshield, applications: ITS( Intelligent Transportation System), ETC(Electronic Toll Collection), vehicle management, parking management.Details

-

CL7203L1Global Class1 Gen2 Standard RFID Card CL7203L1Standard UHF RFID white card CL7203L1: Access control system, VIP card, e- Ticketing, assets management, parking system,library management, working station managemnet, etc..Details

-

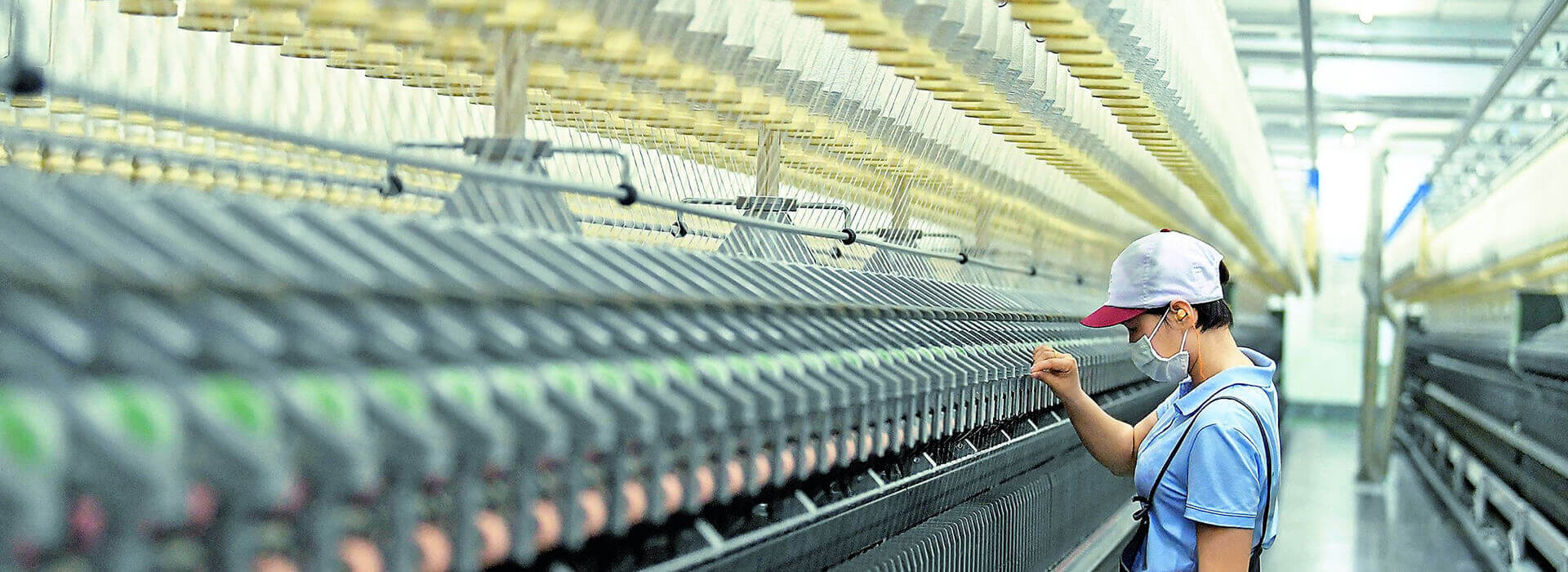

CL7203H-TL7015UHF Textile Laundry Tag Label RFID tag RFID labelThe RFID tags enable uniform companies, hospitality organizations, commercial cleaners, and medical facilities, woven RFID tags for ordinary linen, clothing, pillowcases, etc. It is specially designed to track the health textiles in the harsh environment of the entire laundry industry.Details

-

CL7203S-9522UHF Flexible Metal Label RFID tagThis is a most common and wide use RFID tag - paper label with adhesive, and usually used in fixed assest management, warehousing management, inventory control, medicine tracking and so on.Details