-

Working on metal surfaces

Working on metal surfaces -

128bit rewritable EPC memory

128bit rewritable EPC memory -

>5m long reading distance

>5m long reading distance -

IP65 rugged

IP65 rugged

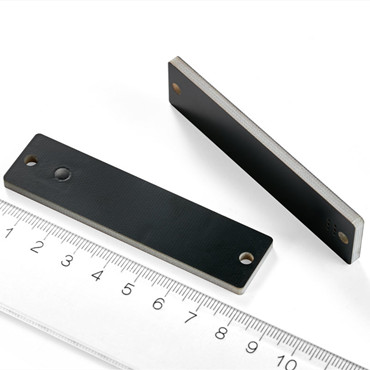

CL7203E series anti-metal RFID smart electronic tag has a recognition distance of up to 8 meters and a high-speed anti-collision mechanism.

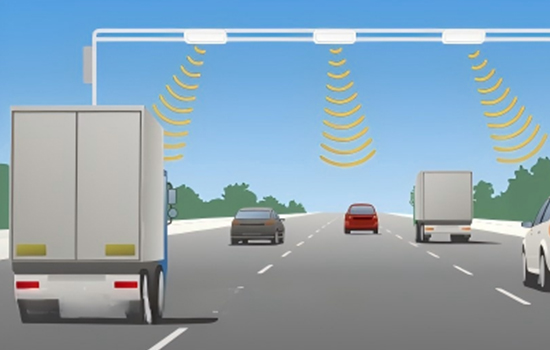

It is suitable for intelligent weighing management, license plate anti-counterfeiting recognition management, vehicle marshaling and dispatching management, intelligent parking lot management, asset management, port entry and exit vehicle inspection management, and terminal container management and many other fields.

CL7203E series anti-metal RFID smart electronic tag has a recognition distance of up to 8 meters and a high-speed anti-collision mechanism.

It is suitable for intelligent weighing management, license plate anti-counterfeiting recognition management, vehicle marshaling and dispatching management, intelligent parking lot management, asset management, port entry and exit vehicle inspection management, and terminal container management and many other fields.

-

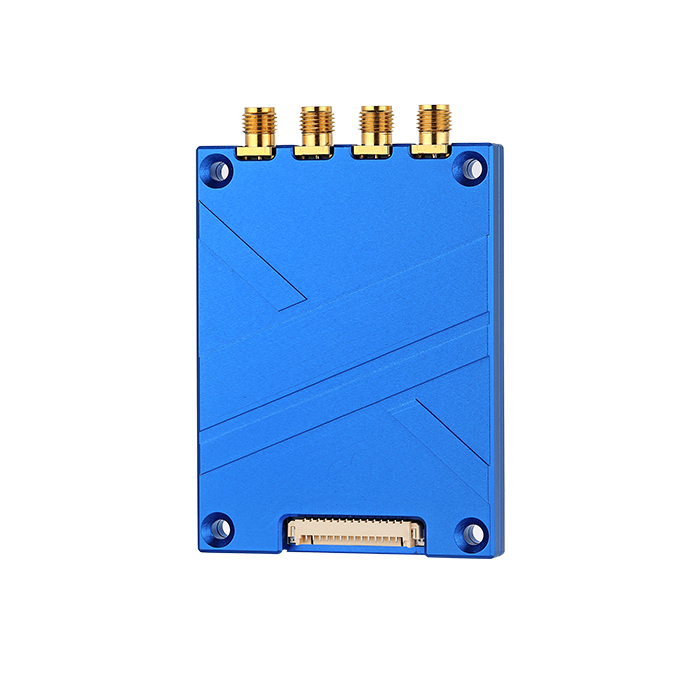

Parameters

Frequency 902MHz~928MHz; ETSI: 865-868MHz Protocol ISO/IEC 18000-6C EPC global GEN2 Class1 Chip NXP Ucode8 Reading range >5m (used Hopeland Fixed Reader) Writing range >1m Memory EPC 128bits Working mode Passive Data storage >10 years Rewriting >100000 times Polarization Liner polarization -

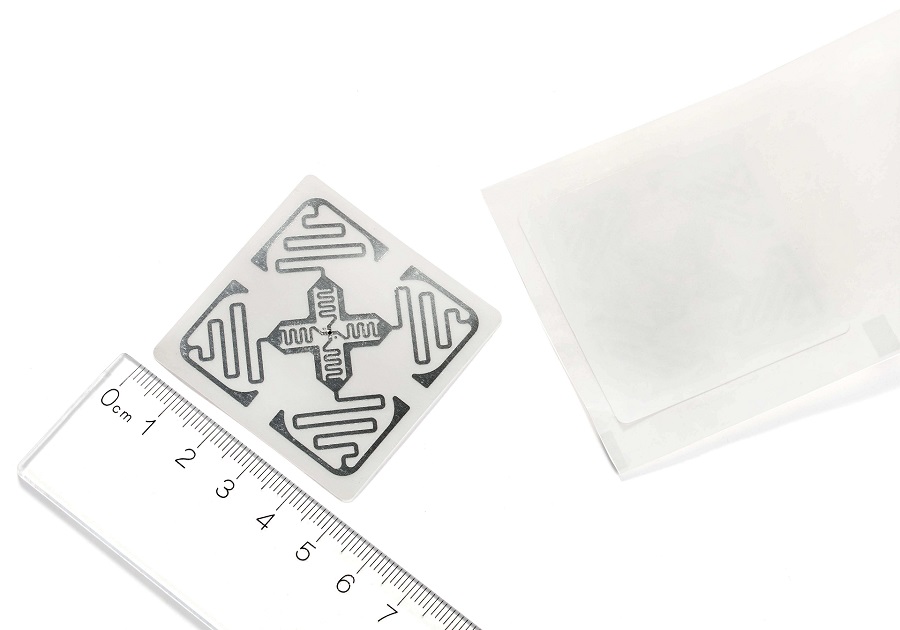

Physical

Size 80mm*20mm*3mm Housing Material PCB (FR4) Weight 20g/pcs Installation by screw or self adhesive Working temperature -25℃~85℃ Storage temperature -30℃~110℃ Relative humidity 5%~95% RH non-condensing

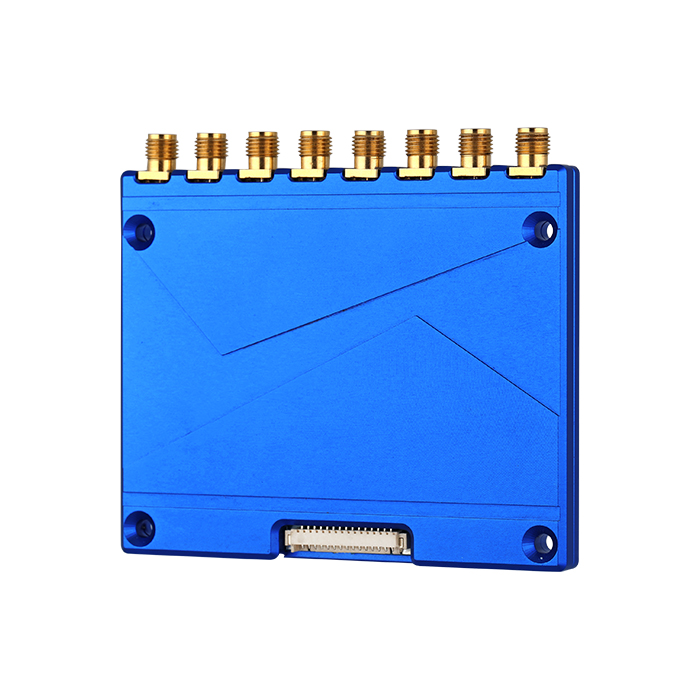

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

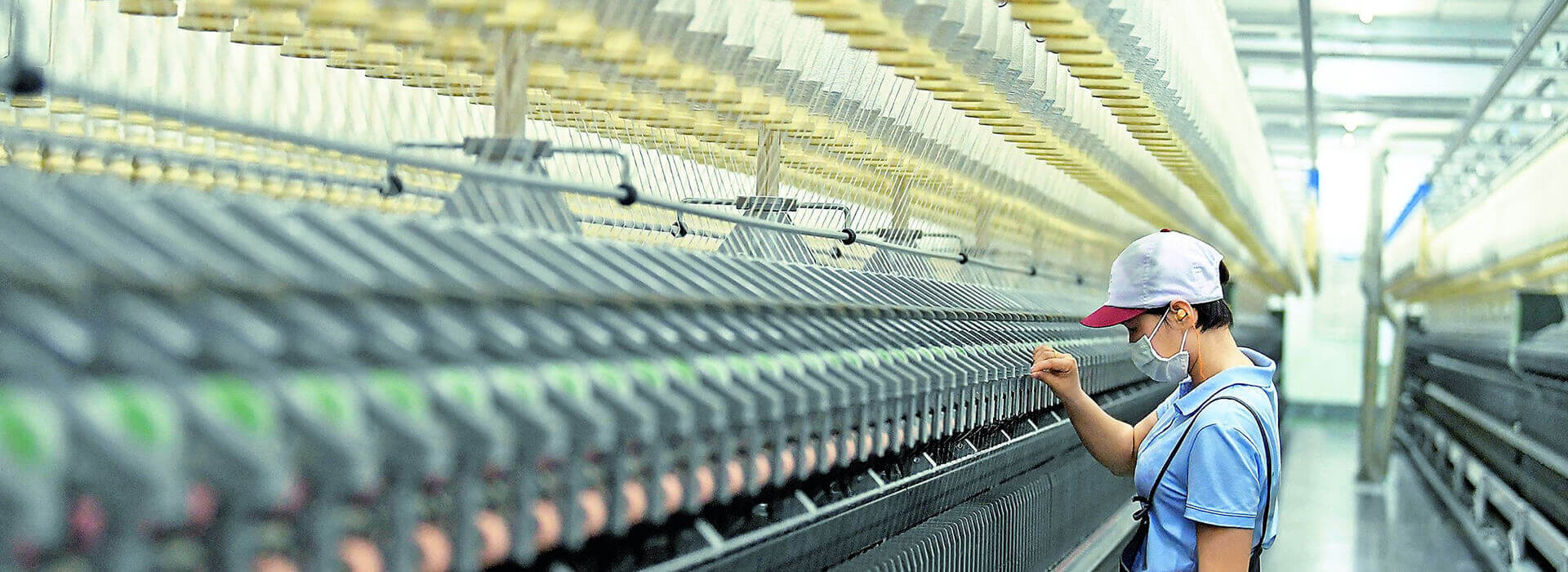

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.

-

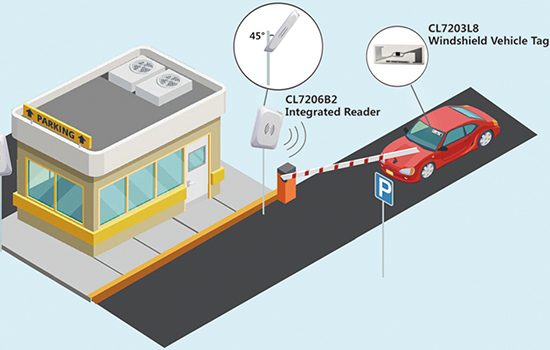

CL7203L8RFID Tag Sticker for Vehicle WindshieldRFID sticker/label fragile, especially designed for vehicle windshield, applications: ITS( Intelligent Transportation System), ETC(Electronic Toll Collection), vehicle management, parking management.Details

-

CL7203E-5213UHF RFID PCB Anti-Metal Tag CL7203E-5213Anti-metal RFID sticker/label, suitable for metal surface, long reading distance & multiple reading: assets management, documents management,equipment management and so on.Details

-

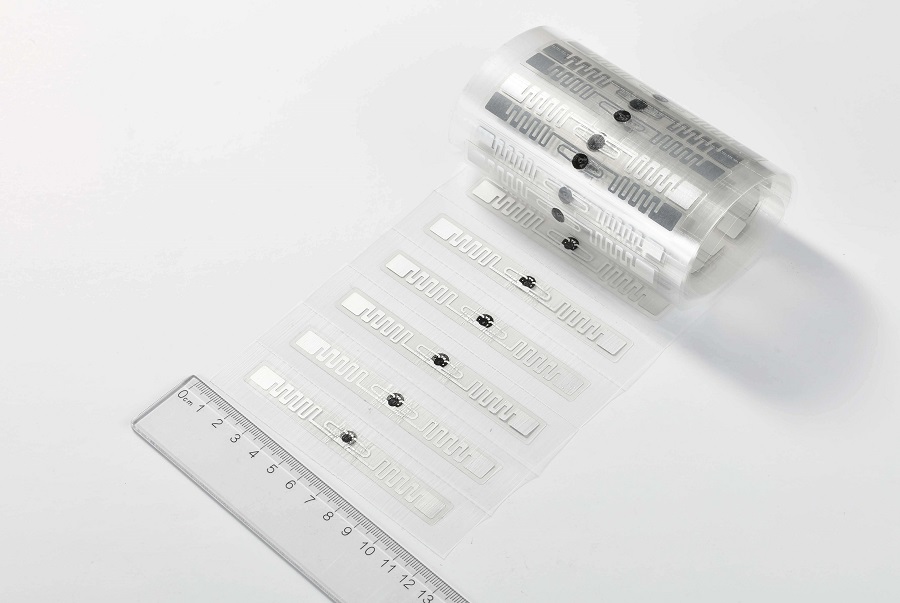

CL7203L-9654UHF Wet Inlay CL7203L-9654Hopeland UHF Wet inlay Use Alien Chipset,Support ISO18000-6C And EPCglobal C1 Gen2 Protocol,Support Multiple Reading,The shape is slender and thin, and it can be easily hidden and installed. It is very suitable for applications in the fields of books, archives and electronic ticket management.Details

-

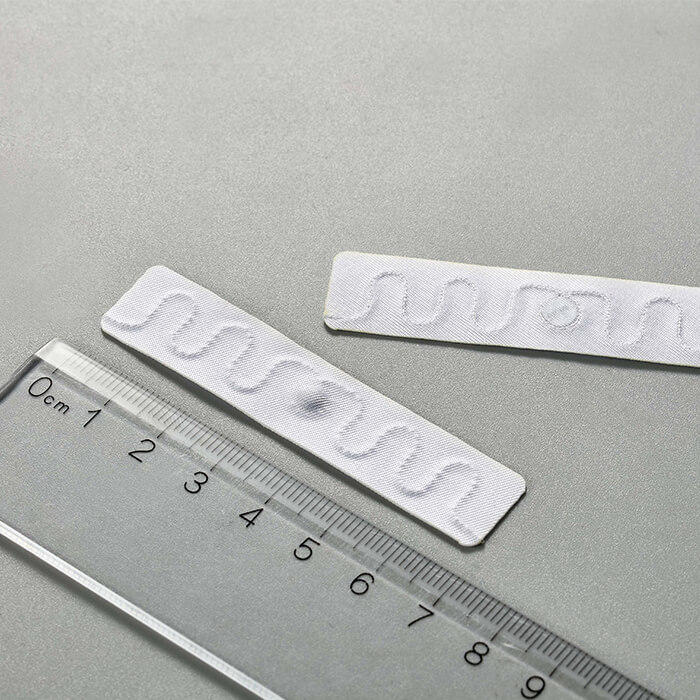

CL7203L-H47UHF Paper LabelHopeland UHF Paper Label Use Impinj Chipset,Support ISO18000-6C and EPCglobal C1 Gen2 Protocol,Support Multiple Reading,The shape is slender and thin, and it can be easily hidden and installed. It is very suitable for applications in the fields of books, archives and electronic ticket management.Details