-

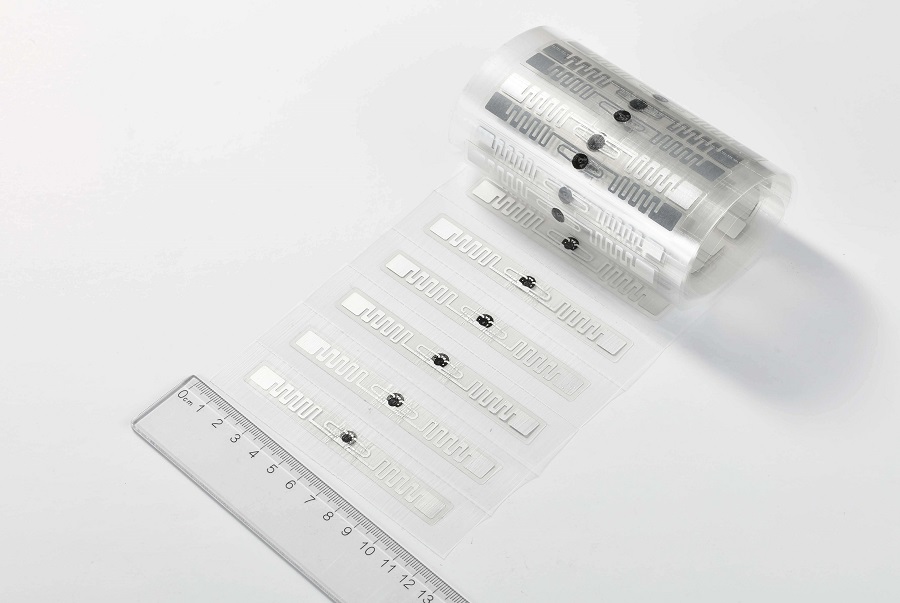

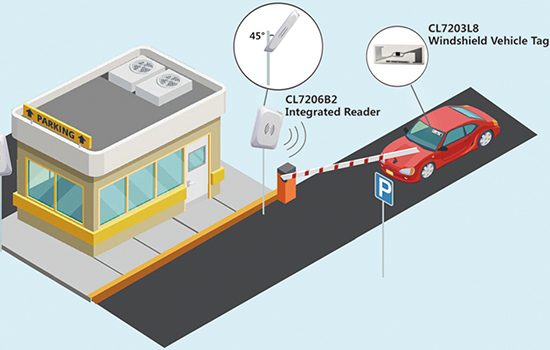

High performance: reading distance up to 8-15m

High performance: reading distance up to 8-15m -

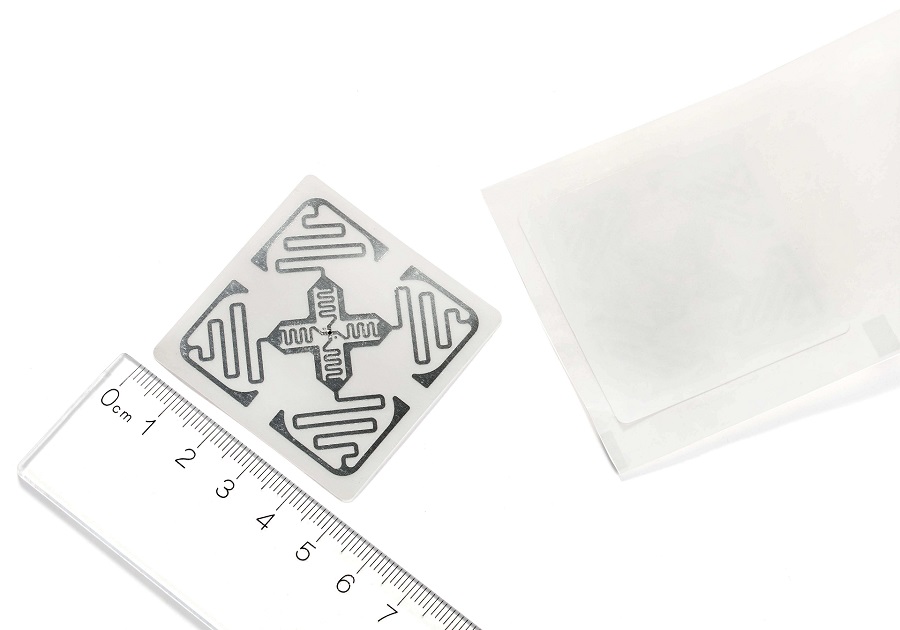

Flexible application: tamper proof, weather proof

Flexible application: tamper proof, weather proof -

For access control system, VIP card, E-ticketing, parking system etc.

For access control system, VIP card, E-ticketing, parking system etc.

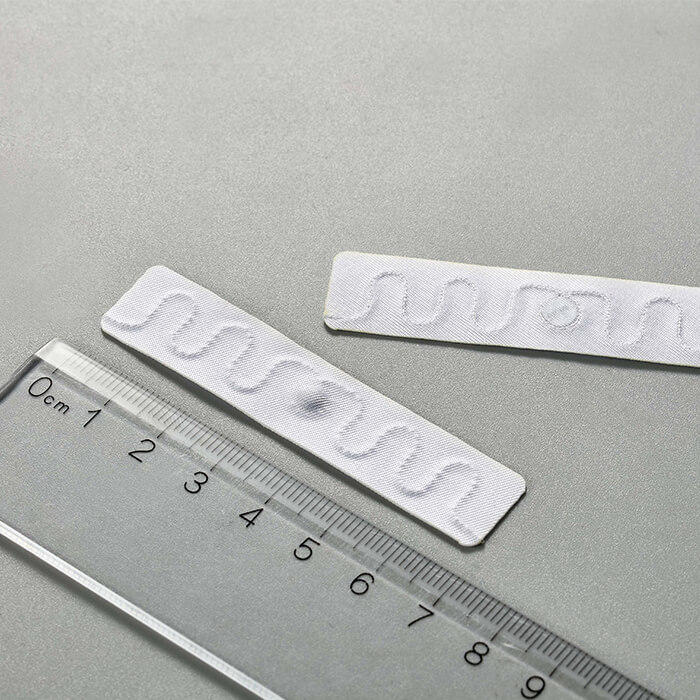

Wide Adaptability, supporting multiple RFID frequency bands such as low frequency, high frequency, and ultra-high frequency, can match different reading and writing devices and application scenarios.

Customized Forms Are Diverse, and exclusive data (such as identity information, permission passwords) can be written according to needs, as well as logos and text can be printed later to meet personalized needs.

Strong Durability, the card material is mostly PVC or ABS, waterproof, wear-resistant, anti bending, long service life, suitable for high-frequency use scenarios.

Wide Adaptability, supporting multiple RFID frequency bands such as low frequency, high frequency, and ultra-high frequency, can match different reading and writing devices and application scenarios.

Customized Forms Are Diverse, and exclusive data (such as identity information, permission passwords) can be written according to needs, as well as logos and text can be printed later to meet personalized needs.

Strong Durability, the card material is mostly PVC or ABS, waterproof, wear-resistant, anti bending, long service life, suitable for high-frequency use scenarios.

-

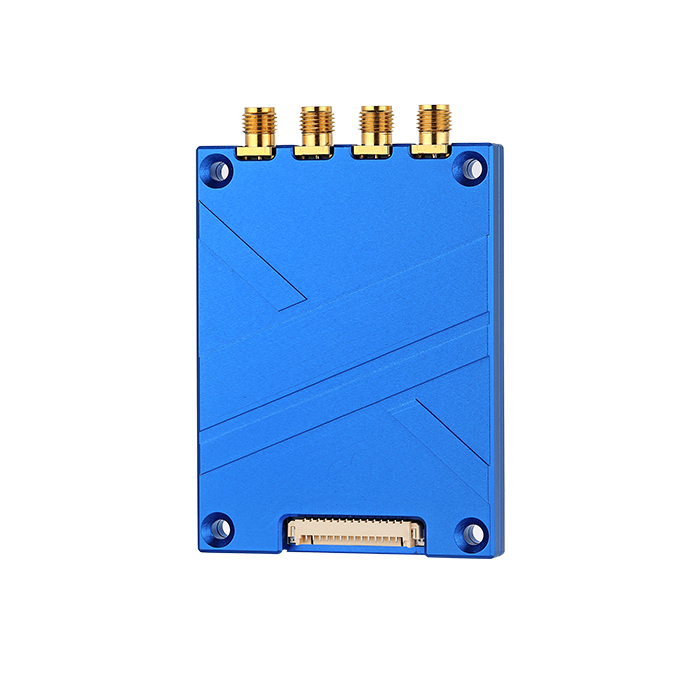

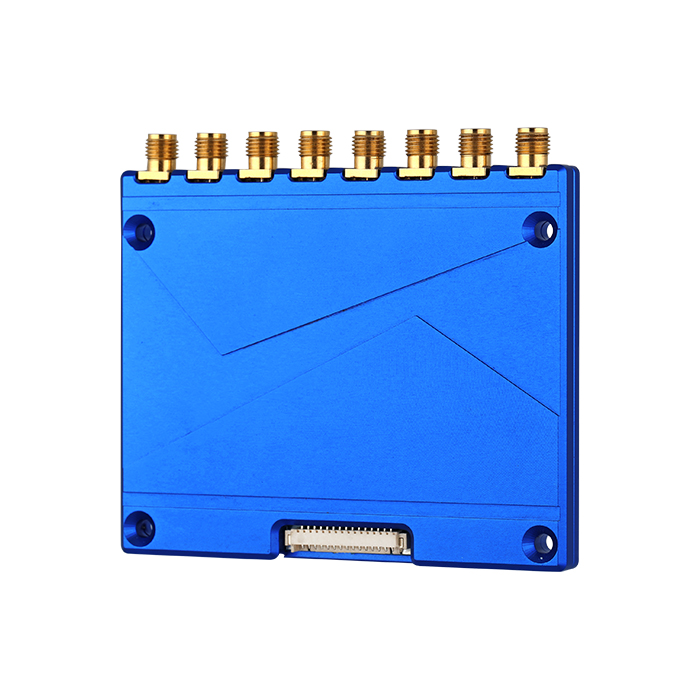

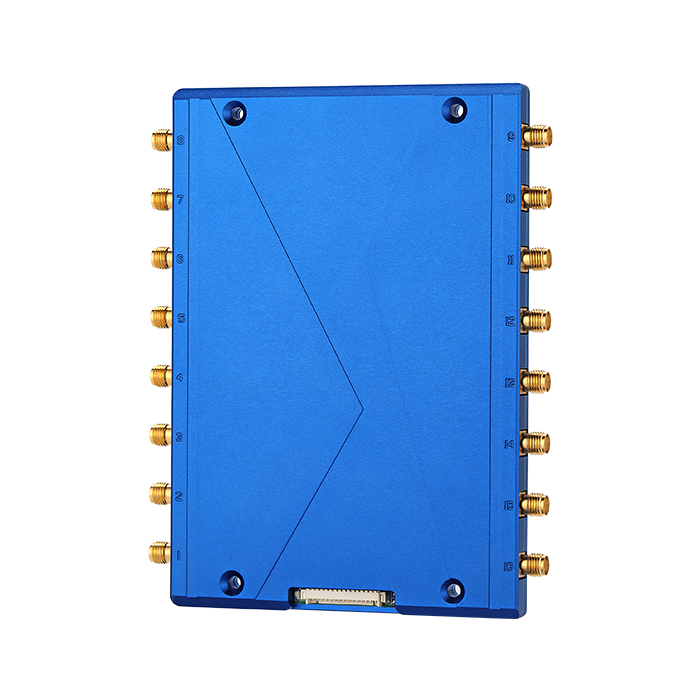

Parameters

Frequency 902MHz~928MHz; ETSI: 865-868MHz Protocol ISO/IEC 18000-6C EPC global GEN2 Class1 Chip R6/R6P/U8/H-EC Polarization Liner polarization Sensitivity -17dB -19dB Reading range 5-20m Writing range 3.5m EPC area 96 to 480bits User area 512bits TID area 96bits -

Physical parameter

Working mode Passive Data storge ISO/IEC 18000-6C,EPC Class1 Gen2 Rewriting >10years Housing Material PVC Weight 7g/pc Package 200pcs/box

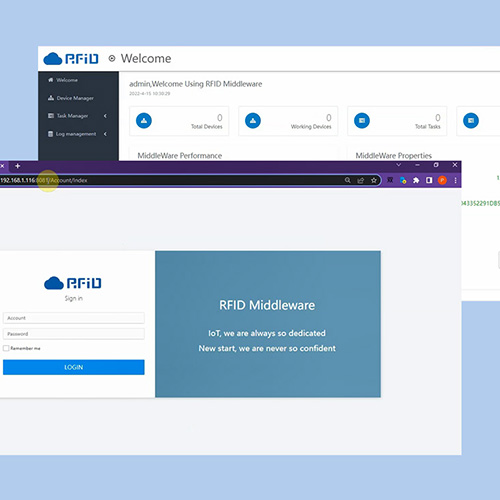

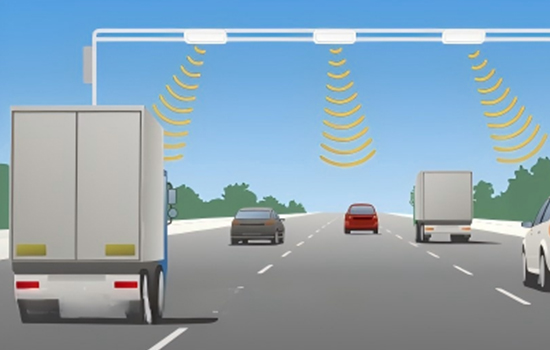

RFID technology (radio frequency identification technology), as a revolutionary solution to security and management, can effectively solve the traffic issues. Hopeland provides a variety of RFID products, including UHF RFID readers, RFID Antennas, RFID vehicle tags, to promote the management of highway toll collections.

Registered vehicles cannot be ensured in the field, although for different zoning, established the identity of cardboard. When we want to find out a specific vehicle, the process will be much time-consuming and cumbersome. Sometimes, some cars are not observed, the presence of area stopped for a long time and has not been sold. The stock situation cannot be timely to be controlled. For this situation, we need to implement automatic vehicle access registration, to achieve partition statistics, sales statistics, long stay and early-warning capabilities, making it imperative. Therefore, we need a new system to replace the existing system, which using more scientific and reasonable methods to reach vehicle monitoring.

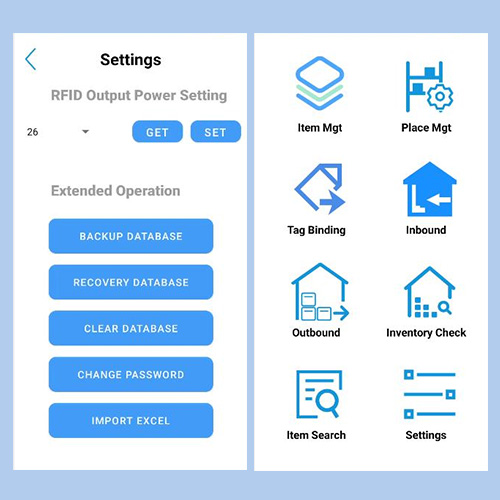

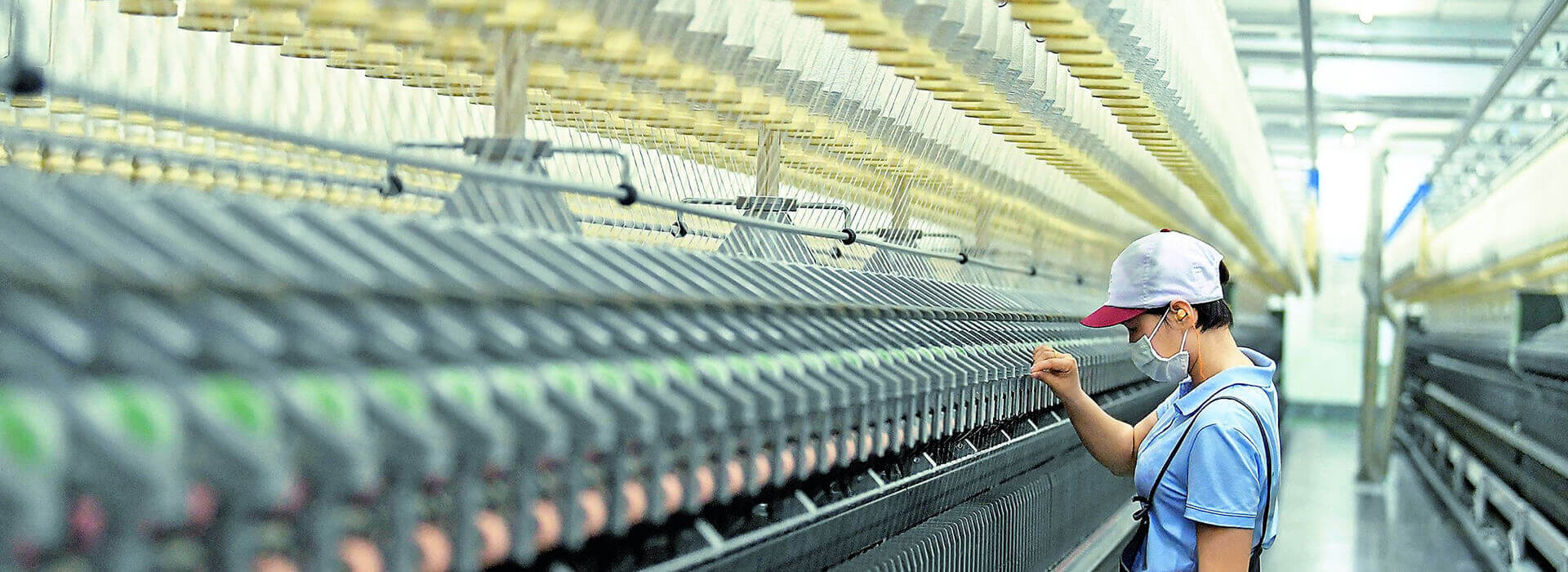

At present, the one-dimensional barcode/two-dimensional barcode identification technology has been widely used in the management of item classification and labeling. However, its barcode technology relies on visible light scanning reflection, has low recognition rate, is easy to break, contaminates, is sensitive to media such as water and oil, and stores a limited amount of information, which affects its application in large-scale logistics management.

RFID radio frequency identification technology is a typical representative of automatic identification technology. It has high recognition accuracy, reliable performance, large amount of stored information, resistance to oil and sewage washing, etc. It is especially suitable for automatic identification requirements in industrial environments. The use of RFID tags to replace barcodes and other identification products can effectively complete the automatic management of warehousing and realize automatic collection, automatic processing and information reporting of product information.

In terms of tool management application technology, traditional automatic identification technologies such as one-dimensional bar code/two-dimensional bar code have also been widely used in the management of item classification and labeling. However, the barcode technology itself relies on the visible light scanning reflection, the recognition rate is low, the barcode is easily damaged and stained, and the amount of stored information is small. Generally, it only identifies a certain type of product, which affects its wide application in logistics management.

Compared with barcode technology, RFID radio frequency identification technology is a typical representative of non-contact long-distance automatic identification technology. RFID technology has high recognition accuracy, reliable performance, large amount of stored information, and oil and sewage resistance, especially suitable for automatic identification requirements in harsh working environments. The use of RFID tags to replace barcodes and other identified goods can effectively complete the automatic management of assets, and realize the automatic collection, automatic processing and report output of asset information.