Application background

With the rapid development of the economy, the steel industry has developed rapidly. The use of steel bars has also increased by nearly 370 times after the reform and opening up. Such a large amount of steel bars is required for inventory management, inventory, anti-theft, and delivery of various models. , anti-counterfeiting, etc., a series of problems are coming one after another, and they need to be solved urgently.

Traditional steel inventory management, inventory, anti-theft, delivery of various models, anti-crossing goods, etc. all require manual operations and records. The efficiency is very low. There may also be recording errors, resulting in incorrect information and affecting customers. Orders lead to the loss of corporate assets, and it is quite difficult to solve them manually.

solution

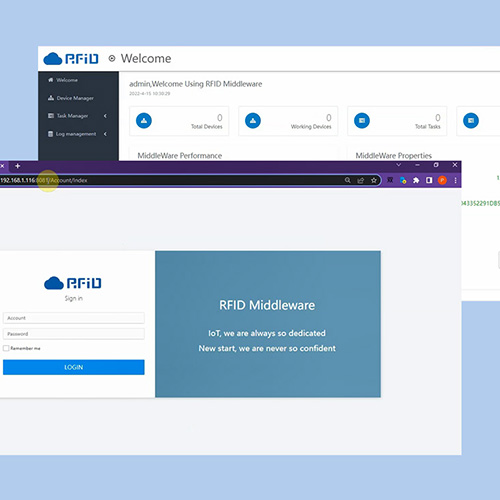

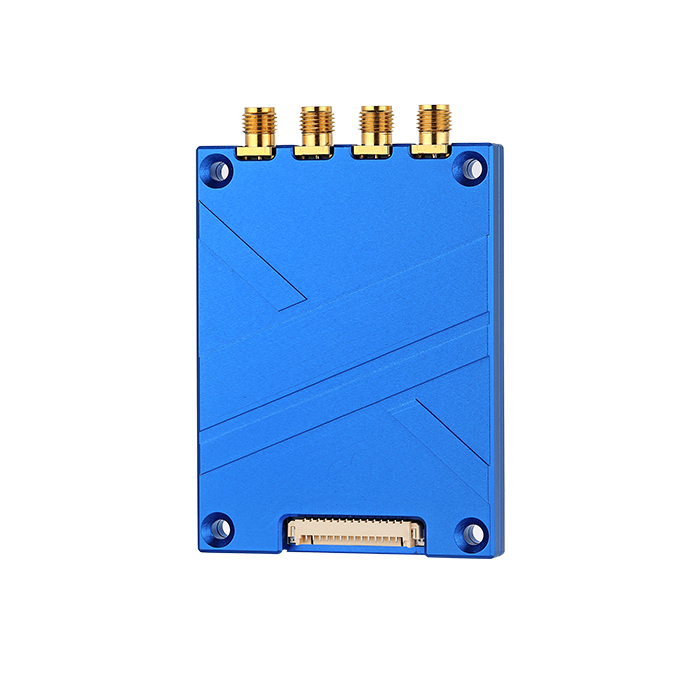

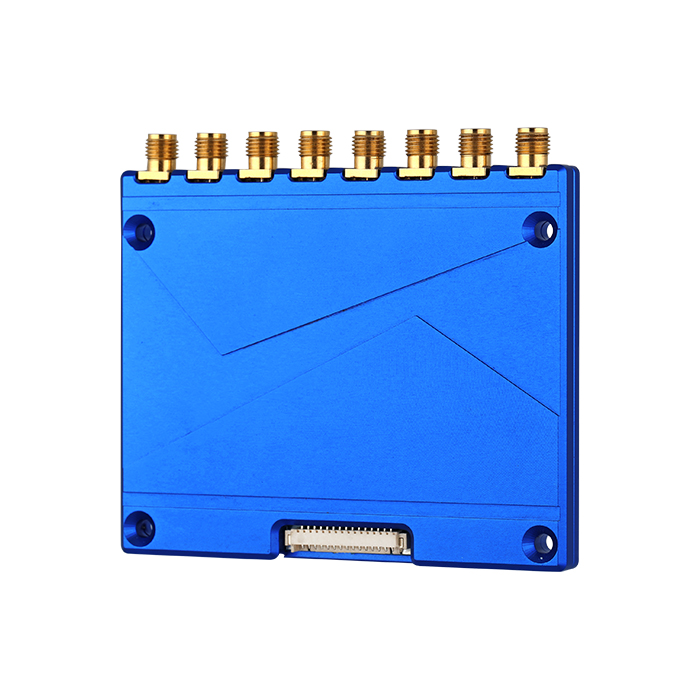

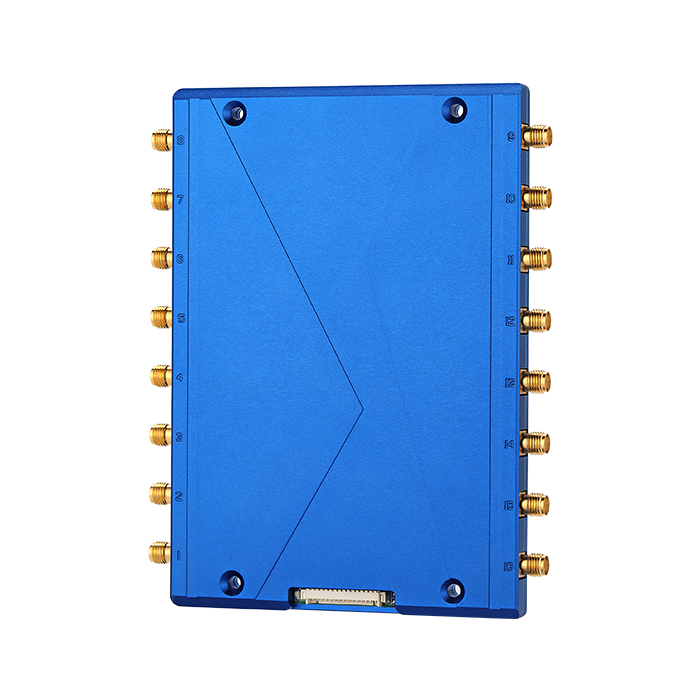

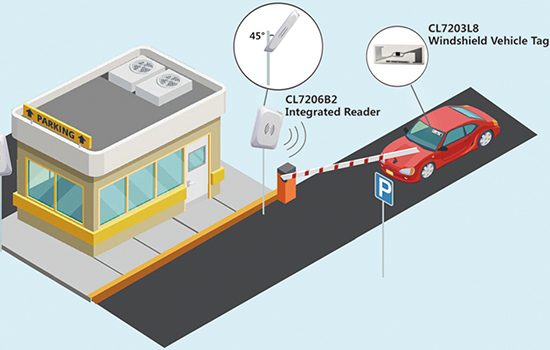

Introduce RFID long-distance radio frequency identification technology for management to achieve quick and real-time understanding of all material information in the warehouse. The possibility of sending the wrong goods is also greatly reduced. Information such as the quantity and model of steel entering and exiting the warehouse are also automatically collected and uploaded in a timely manner. This avoids the occurrence of manual errors. The RFID steel warehouse management system can see the current steel inventory information in real time on the background computer, which greatly improves inventory efficiency and prevents wrong shipments. The impact on the loss of company assets and customer orders will be greatly improved.

Application details

1. Steel warehouse inventory inventory

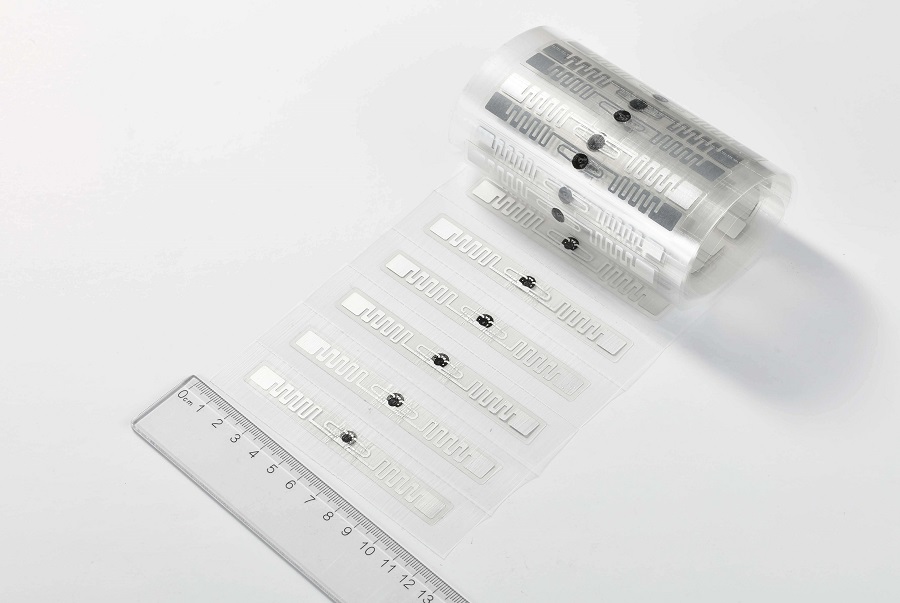

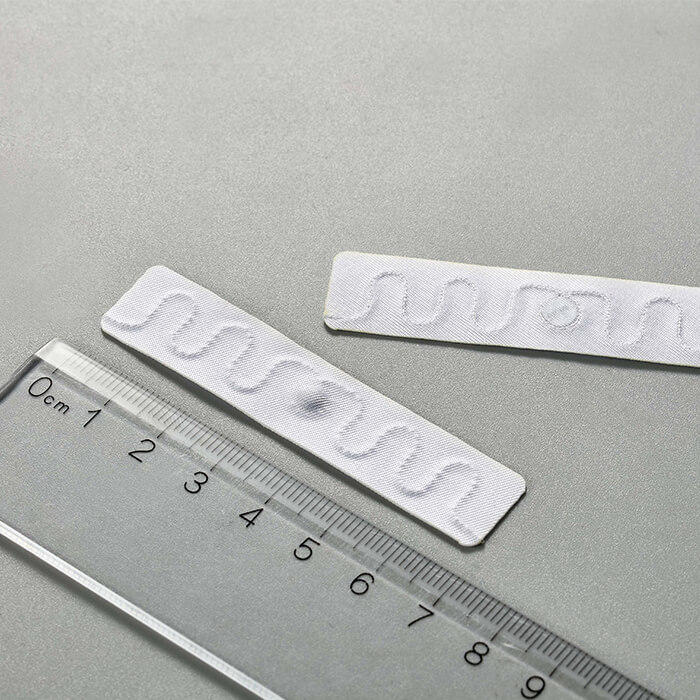

Install RFID tags on the sides of each bundle of steel bars and attach them to the sides of the steel bars. Install the RFID reader on the corresponding wall with the tag and upload the data to the backend system

2. Steel bars in and out of warehouse

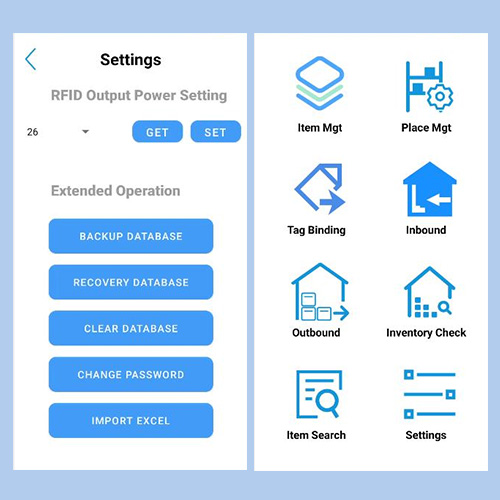

When the warehouse keeper gets the picking list, he can directly use the back-end software to check which area of the warehouse the essential items are in. Then he brings a handheld device to read the tags in the area to see if it is the item he needs. If so, If it is confirmed that the goods are essential, the crane can be notified to start lifting the swept bundles of steel bars. After all the goods are loaded and the truck is about to take away the goods, the warehouse manager will use the handheld phone to check the goods at the door of the warehouse. All goods are scanned again, and after confirming again that they are correct, the truck can be released.